4.16

ELECTRONIC FUEL INJECTION

CRANKSHAFT POSITION SENSOR

(CPS)

Operation Overview

The engine speed sensor is essential to engine operation,

constantly monitoring the rotational speed (RPM) and position

of the crankshaft.

A ferromagnetic 60-tooth ring gear with two consecutive teeth

missing is mounted on the flywheel. The inductive speed sensor

is mounted 1.0 0.26 mm (0.059 0.010 in.) away from the

ring gear. During rotation, an AC pulse is created within the

sensor for each passing tooth. The ECU calculates engine speed

from the time interval between the consecutive pulses. The two-

tooth gap creates an “interrupt” input signal, corresponding to

specific crankshaft position for PTO cylinder. This signal serves

as a reference for the control of ignition timing by the ECU.

Synchronization of the CPS and crankshaft position takes place

during the first two revolutions each time the engine is started.

This sensor must be properly connected at all times. If the sensor

fails or becomes disconnected for any reason, the engine will

quit running.

CPS Test

The crankshaft position sensor is a sealed, non-serviceable

assembly. If fault code diagnosis indicates a problem within this

area, test and correct as follows:

1. Disconnect main harness connector from ECU.

2. Connect an ohmmeter between the pin terminals. A

resistance value of 560 10% at room temperature (20

C, 68 F) should be obtained. If resistance is correct, check

the mounting, air gap, toothed ring gear (damage, runout,

etc.), and flywheel key.

3. Disconnect speed sensor connector from wiring harness.

(the connector with one heavy black lead) Viewing the

connector with dual aligning rails on top, test resistance

between the terminals. A reading of 560 10% should

again be obtained.

NOTE: If the resistance is incorrect, remove the

screw securing the sensor to the mounting bracket

and replace the sensor. If the resistance in step 2

was incorrect, but the resistance of the sensor alone

was correct, test the main harness circuit between

the sensor connector terminals and the

corresponding pin terminals in the main connector.

Correct any observed problem, reconnect the

sensor, and perform step 2 again.

CPS Replacement

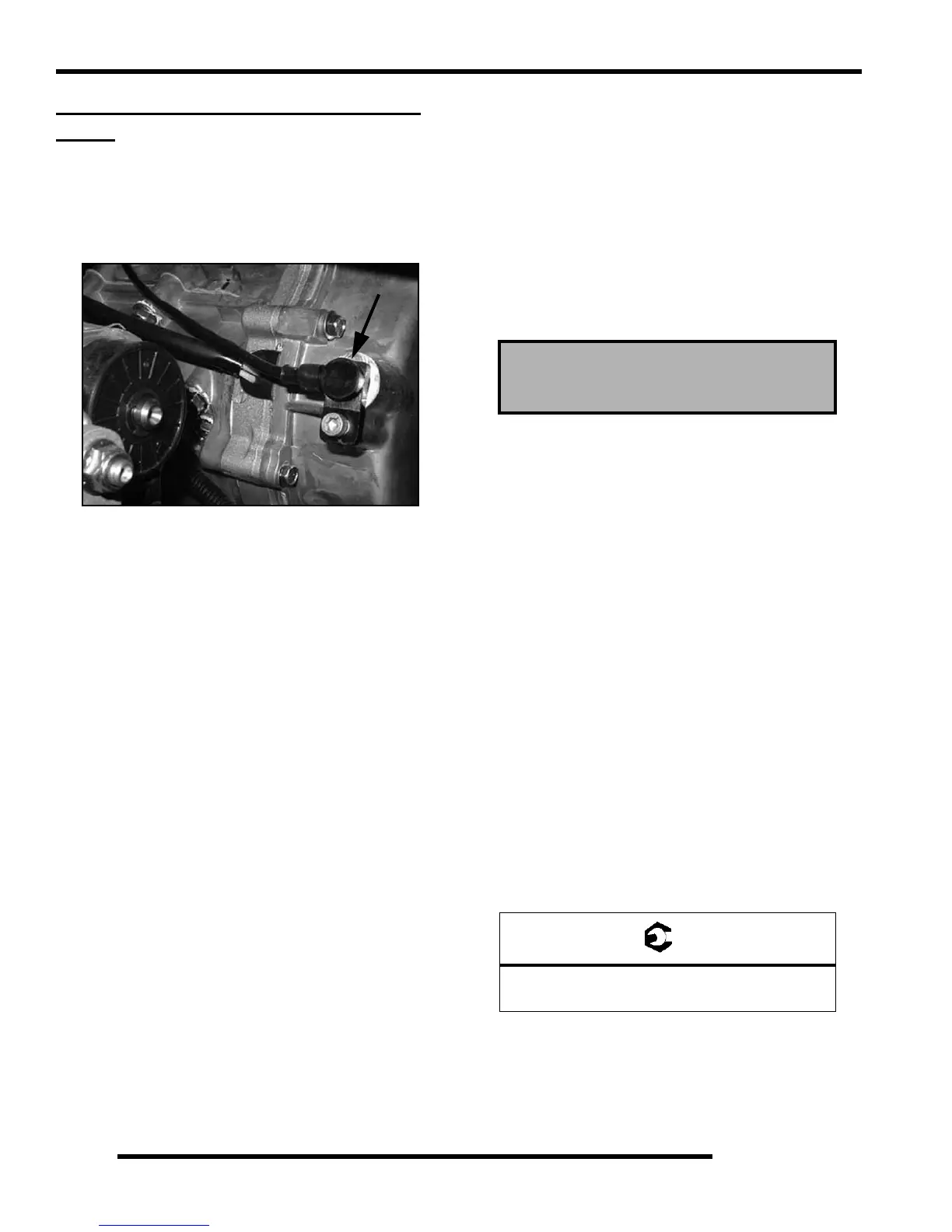

1. Disconnect sensor harness connector.

2. Using a 6 mm hex wrench, remove the retaining bolt and

replace the sensor, using a light coating of oil on the o-ring

to aid installation.

3. Torque the retaining bolt to specification.

Crankshaft Position Sensor:

560

10% (20 C, 68 F)

= T

CPS Retaining Bolt Torque:

25 in. lbs. (2.8 Nm)

Loading...

Loading...