6.9

CLUTCHING

6

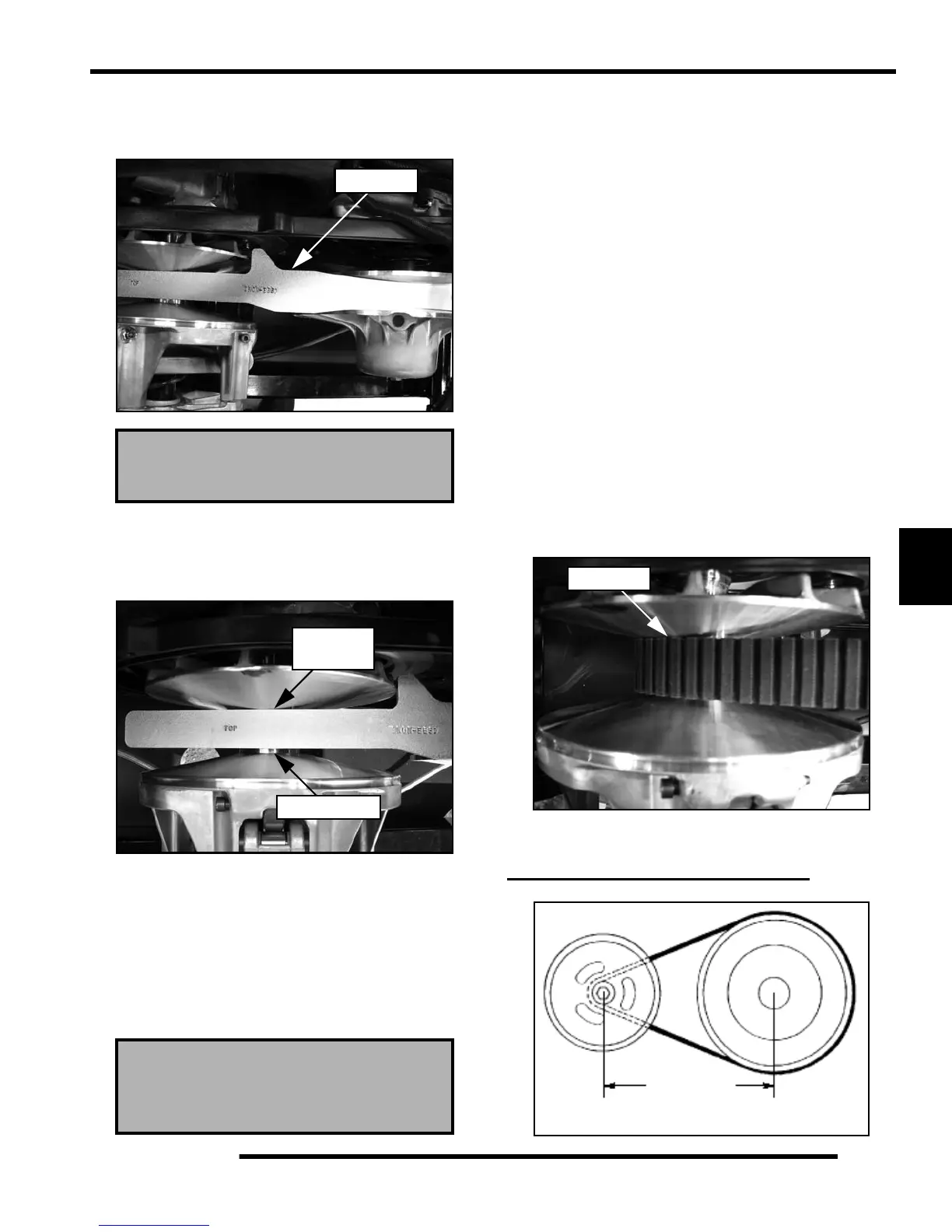

7. Place the alignment tool in the sheaves of the driven clutch

and hold firmly as you rotate it down between the sheaves

of the drive clutch.

8. As you rotate the tool down between the drive clutch

sheaves, the tool should touch the clutch shaft bearing while

maintaining a clearance of roughly .020” between the tool

and stationary sheave of the drive clutch.

9. If the alignment tool hits the stationary sheave before it

reaches the shaft bearing, the driven clutch will need to be

spaced out to correct the alignment.

• Remove the driven clutch. Add the required amount of

alignment washers to obtain the correct measurement

with the alignment tool. You may need to add more

than one alignment washer.

10. If the alignment tool touches the shaft bearing but has an

excessive amount of clearance between the tool and

stationary sheave, the driven clutch will need to be moved

in to correct the alignment.

• Remove the driven clutch. Remove the required

amount of washers to obtain roughly .020” clearance

between the tool and stationary sheave.

NOTE: The number of washers behind the driven

clutch will vary between vehicles.

IMPORTANT: It may not be possible to achieve

perfect alignment with the tool as previously

described, because of the thickness of the alignment

washers. It is better to have clearance between the

tool and stationary sheave of the drive clutch than to

have the tool touch the stationary sheave before it

touches the shaft bearing.

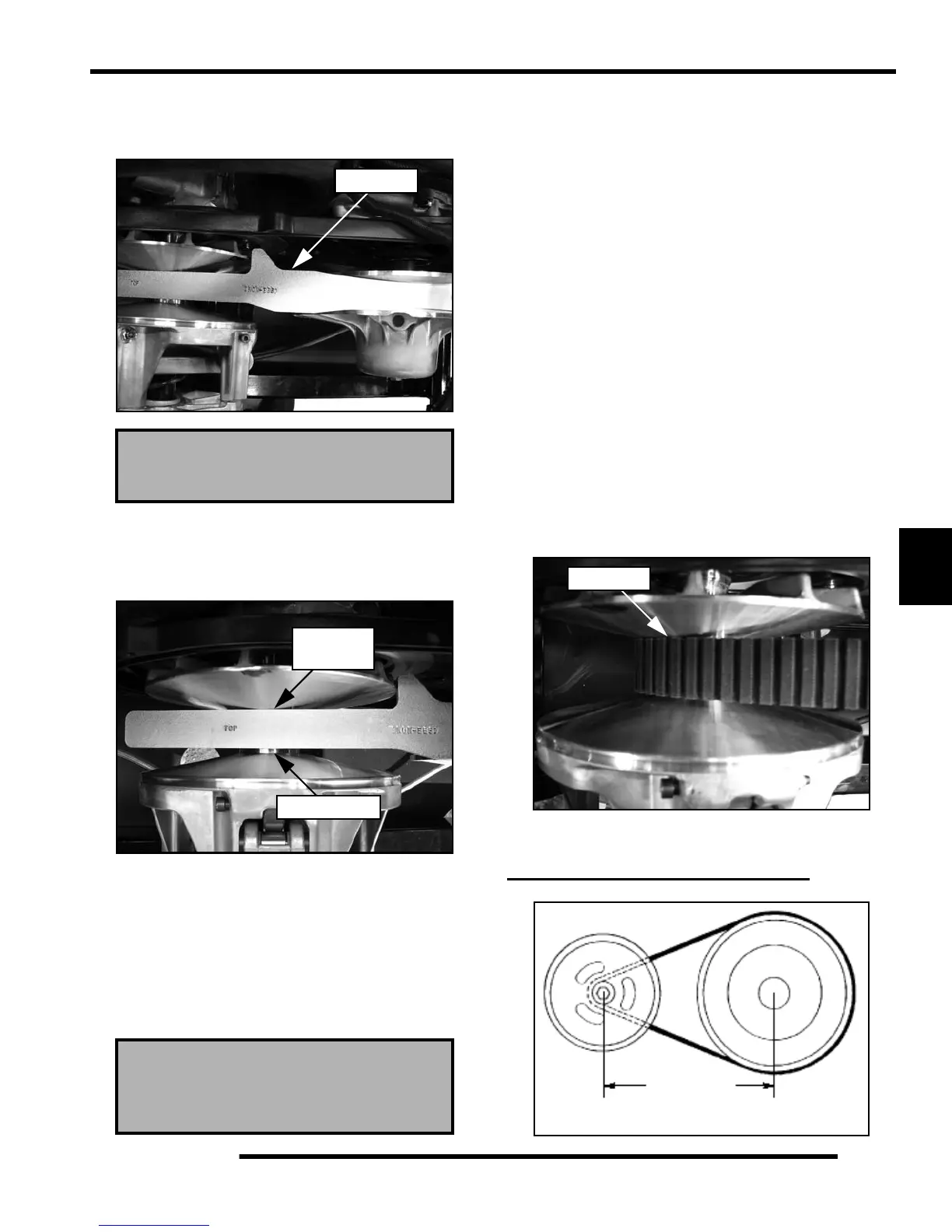

11. After completing the clutch alignment procedure, the belt

should ride in the drive clutch with an approximate .020”

gap between the belt and stationary sheave and a larger gap

of approximately .130” between the belt and moveable

sheave.

CLUTCH CENTER DISTANCE

Clutch Alignment Tool

PA-49011

Alignment Washers

(.030”) PN: 7556454

(.060”) PN: 7556120

PA-49011

Stationary

Sheave

Shaft Bearing

.020” Gap

Center

Distance

10.05 in. / 255 mm

Loading...

Loading...