10.28

ELECTRICAL

Specific Gravity Test

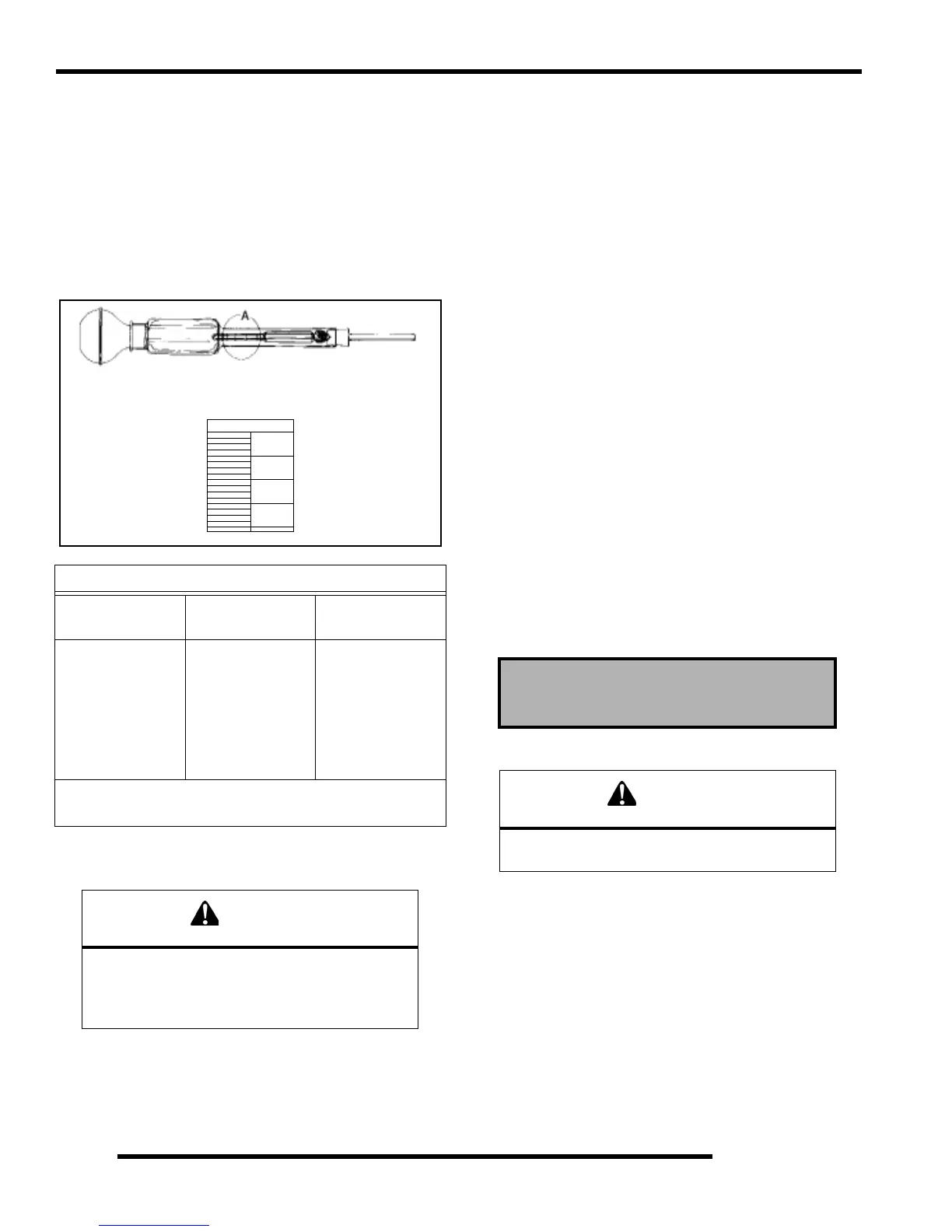

A tool such as a Battery Hydrometer (PN 2870836) can be used

to measure electrolyte strength or specific gravity. As the battery

goes through the charge/discharge cycle, the electrolyte goes

from a heavy (more acidic) state at full charge to a light (more

water) state when discharged. The hydrometer can measure

state of charge and differences between cells in a multi-cell

battery. Readings of 1.270 or greater should be observed in a

fully charged battery. Differences of more than .025 between the

lowest and highest cell readings indicate a need to replace the

battery.

Load Test

NOTE: This test can only be performed on machines

with electric starters. This test cannot be performed

with an engine or starting system that is not working

properly.

A battery may indicate a full charge condition in the OCV test

and the specific gravity test, but still may not have the storage

capacity necessary to properly function in the electrical system.

For this reason, a battery capacity or load test should be

conducted whenever poor battery performance is encountered.

To perform this test, hook a multitester to the battery in the same

manner as was done in the OCV test. The reading should be 12.6

volts or greater. Engage the starter and observe the battery

voltage while cranking the engine. Continue the test for 15

seconds. During cranking the observed voltage should not drop

below 9.5 volts. If the beginning voltage is 12.6 volts or higher

and the cranking voltage drops below 9.5 volts during the test,

replace the battery.

Off Season Storage

See Chapter 2 “Maintenance” for battery service procedures.

Charging Procedure

1. Remove the battery to prevent damage from leaking or

spilled acid during charging.

2. Charge the battery with a charging output no larger than 1/

10 of the battery’s amp/hr rating. Charge as needed to raise

the specific gravity to 1.270 or greater.

3. Install battery in vehicle with positive terminal toward the

front. Coat threads of battery bolt with a corrosion resistant

dielectric grease.

4. Connect battery cables.

5. After connecting the battery cables, install the cover on the

battery and attach the hold down strap.

6. Install clear battery vent tube from vehicle to battery vent.

WARNING: Vent tube must be free from obstructions and

kinks and securely installed. If not, battery gases could

accumulate and cause an explosion. Vent should be routed

away from frame and body to prevent contact with

electrolyte. Avoid skin contact with electrolyte, as severe

burns could result. If electrolyte contacts the vehicle frame,

corrosion will occur.

7. Route cables so they are tucked away in front and behind

battery.

SPECIFIC GRAVITY

State of Charge*

Conventional

Lead-Acid

YuMicron™ Type

100% Charged 1.265 1.275

75% Charged 1.210 1.225

50% Charged 1.160 1.175

25% Charged 1.120 1.135

0% Charged less than 1.100 less than 1.115

* At 80° F

NOTE: Subtract .01 from the specific gravity reading at 40° F.

CAUTION

To prevent shock or component damage,

remove spark plug high tension leads and

connect securely to engine ground

before proceeding.

1.10

1.15

1.20

1.25

1.30

Detail A

Battery Hydrometer (PN 2870836)

Dielectric Grease

(PN 2871329)

WARNING

To avoid the possibility of explosion, connect

positive (+) cable first and negative (-) cable last.

Loading...

Loading...