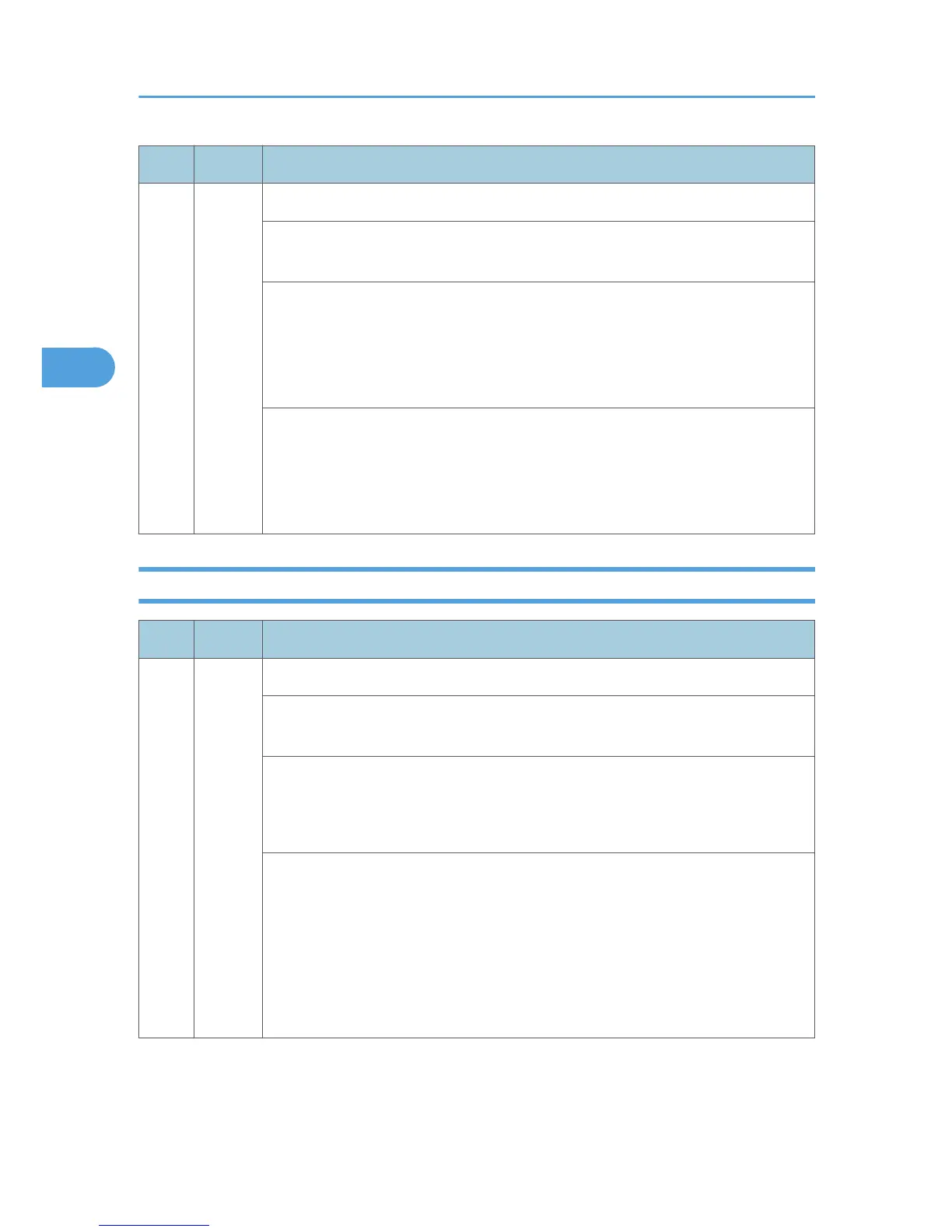

No. Type Details (Symptom, Possible Cause, Troubleshooting Procedures)

392 B

TD sensor initial setting error

Initialization of the new PCU unit failed (the drum and development roller did not

start rotating)

• ID sensor harness loose, broken

•

TD sensor harness loose, broken

•

ID sensor defective

• TD sensor defective

1. Replace the harness of the ID sensor.

2. Replace the the ID sensor.

3.

Replace the harness of the TD sensor.

4. Replace the TD sensor.

SC4xx: Image Processing - 3

No. Type Details (Symptom, Possible Cause, Troubleshooting Procedures)

401 D

Transfer roller leak error 1

A transfer roller current leak signal wad detected. (The current feedback signal for

the transfer roller was not detected within the correct time.)

• High voltage supply board set incorrectly or defective

• Transfer roller set incorrectly or damaged

•

Transfer unit set incorrectly

1. Check the high voltage supply board is set correctly.

2. Check the harness of the high voltage supply board.

3.

Replace the high voltage supply board.

4. Check the transfer roller is set correctly.

5. Replace the transfer roller.

6. Check the transfer unit is set correctly.

3. Appendix: Service Call Conditions

56

Loading...

Loading...