326 Rockwell Automation Publication 2080-UM002N-EN-E - November 2022

Appendix E PID Function Blocks

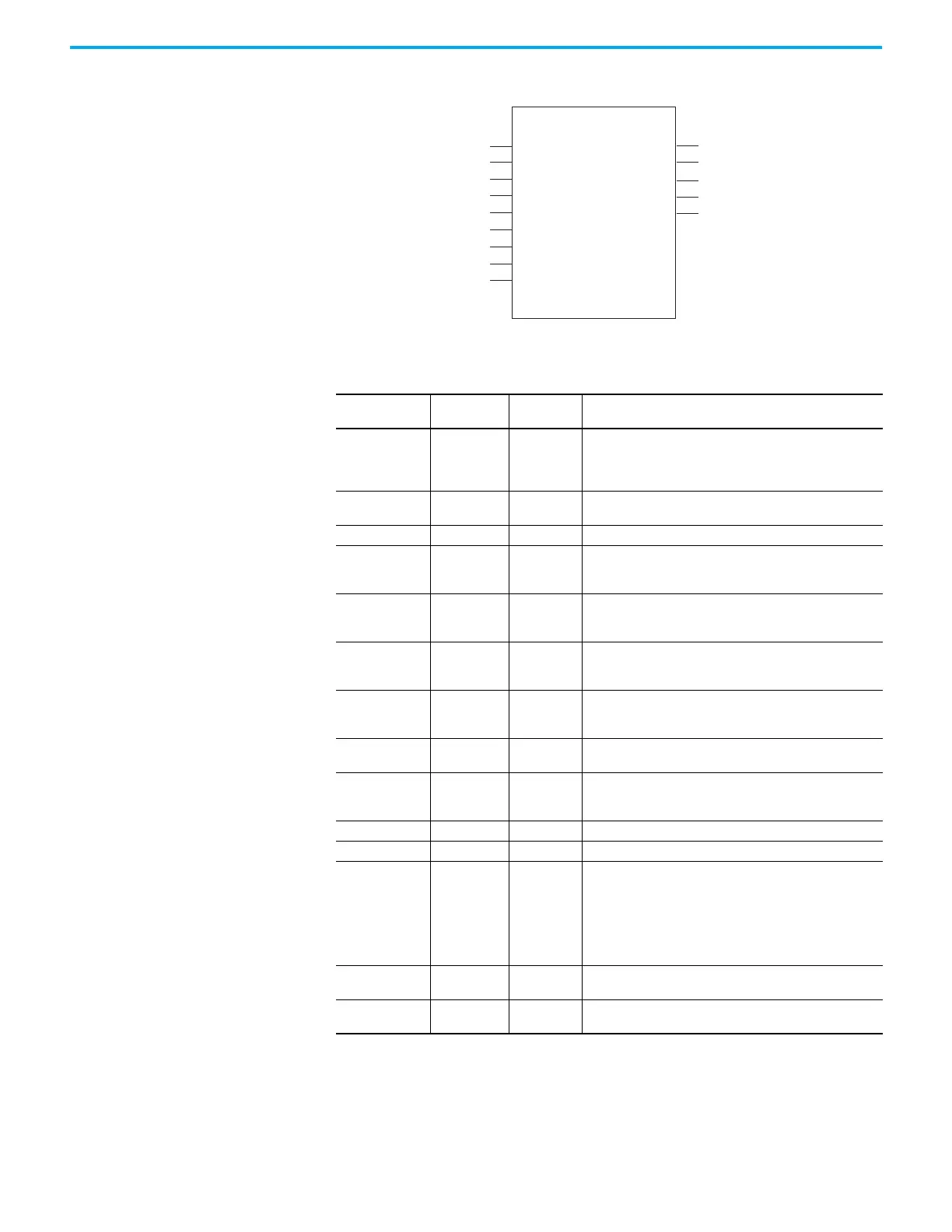

IPIDCONTROLLER Function

Block

This function block diagram shows the arguments in the IPIDCONTROLLER function block.

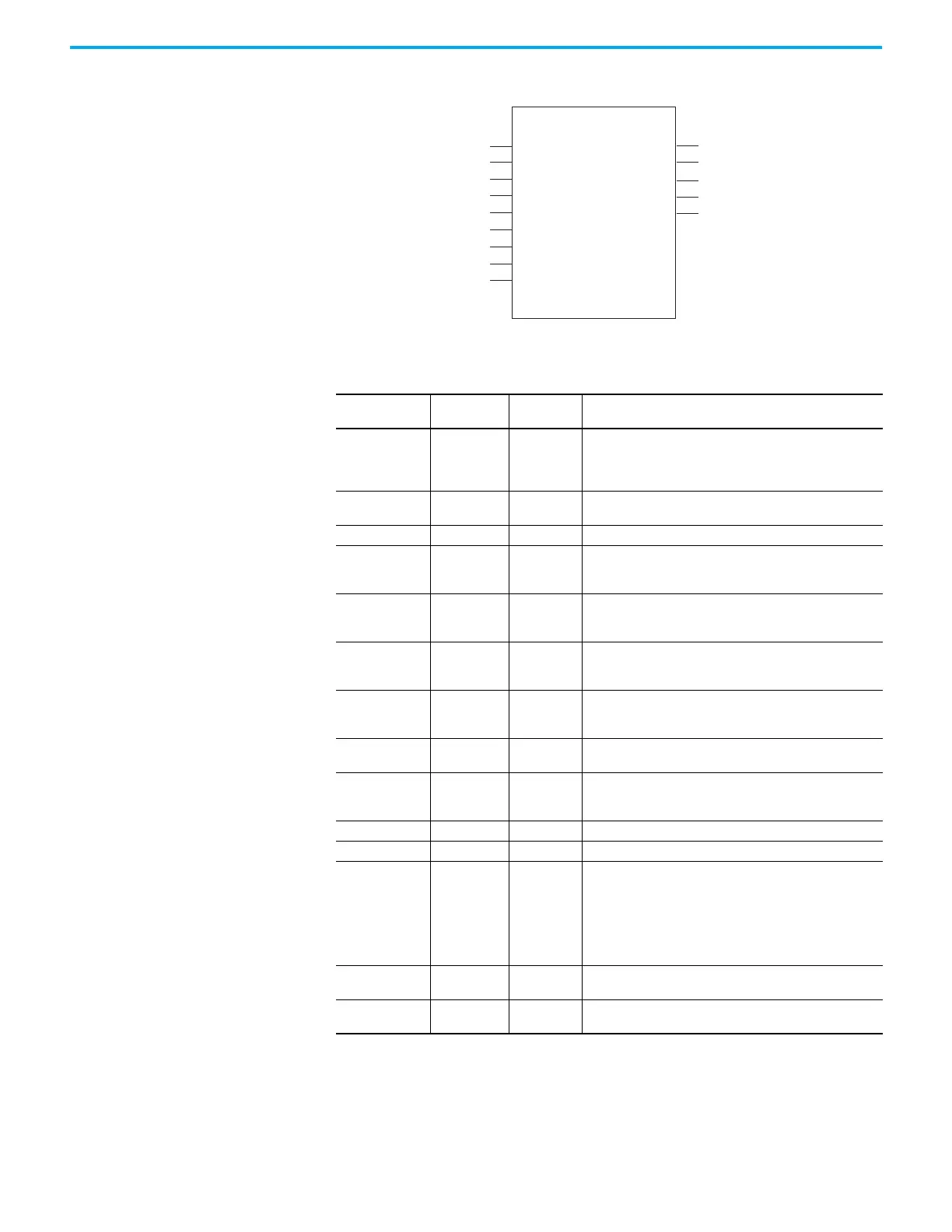

The following table explains the arguments used in this function block.

Table 86 - IPIDCONTROLLER Arguments

Parameter

Parameter

Type

Data Type Description

EN Input BOOL

Function block enable

TRUE = Execute function.

FALSE = Do not execute function.

Applicable to Ladder Diagram programs.

Process Input REAL

Process value, which is the value measured from the process

output.

SetPoint Input REAL The set point value for the process.

Feedback Input REAL

Feedback signal, which is the value of the control variable

applied to the process.

For example, the feedback can be IPIDCONTROLLER output.

Auto Input BOOL

Operating modes of PID controller:

TRUE = Normal operation of PID.

FALSE = Output tracks Feedback.

Initialize Input BOOL

A change in value (TRUE to FALSE or FALSE to TRUE) causes

the controller to eliminate any proportional gain during that

cycle. It also initializes AutoTune sequences.

Gains Input GAIN_PID

Gains PID for IPIDCONTROLLER.

Use the GAIN_PID data type to define the parameters for the

Gains input.

AutoTune Input BOOL

TRUE = Autotune.

FALSE = No Autotune.

ATParameters Input AT_Param

AutoTune parameters

Use AT_Param data type to define the parameters for the

ATParameters input.

Output Output Real Output value from the controller.

AbsoluteError Output Real Absolute error (Process - SetPoint) from the controller.

ATWarnings Output DINT

Warning for the AutoTune sequence. Possible values are:

0 = No auto tune done.

1 = In auto tune mode.

2 = Auto tune done.

-1 = Error 1: Input automatically set to TRUE, no auto tune

possible.

-2 = Error 2: Auto tune error, the ATDynamSet expired.

OutGains Output GAIN_PID

Gains calculated from AutoTune Sequences.

Use GAIN_PID data type to define the OutGains output.

ENO Output BOOL

Enable output.

Applicable to Ladder Diagram programs.

IPIDCONTROLLERIPIDCONTROLLER

Process

ENO

Output

AbsoluteErrorSetPoint

FeedBack

Auto

Initialize

Gains

AutoTune

ATParameters

ATWarning

OutGains

EN

Loading...

Loading...