Integration into the User Program

4-29

C7-613 Control System

A5E00138934-03

4.6.1 Operational Messages and Fault Messages

Triggering Messages

Messages are triggered by setting a bit in the message area. The position of the

message area is specified with the “EVENTS” parameter.

Message Area

A message area can be specified for messages 1 to 127.

As soon as the bit is set in the message area and the “EVENT” FB has been run,

the fault/operational message is entered as “arrived” in the event buffer. In

addition, flashing fault messages appear on the display.

After resetting the same bit, the message is recorded as “gone”.

There is no message area and no message bit for Message 0 (idle message).

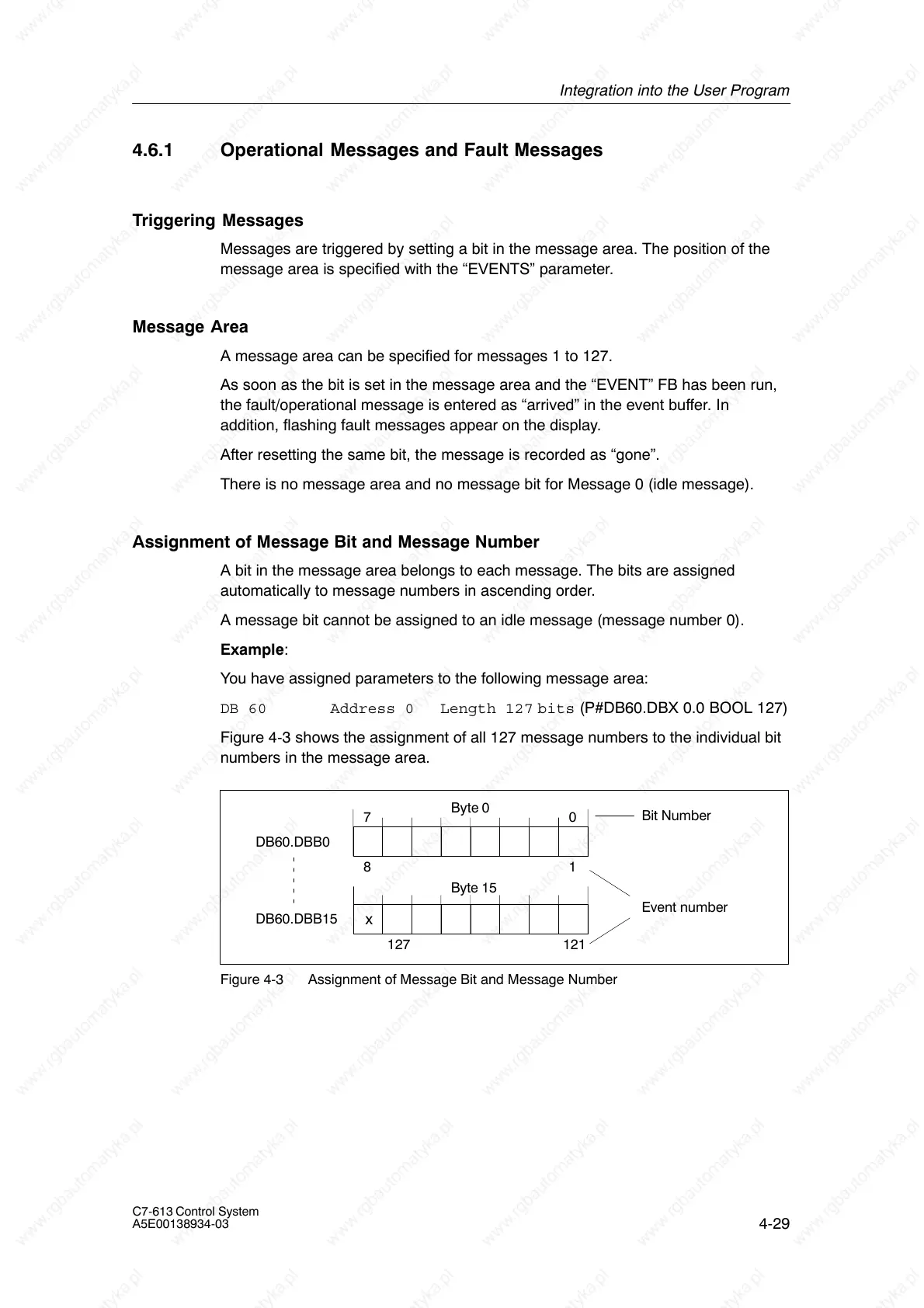

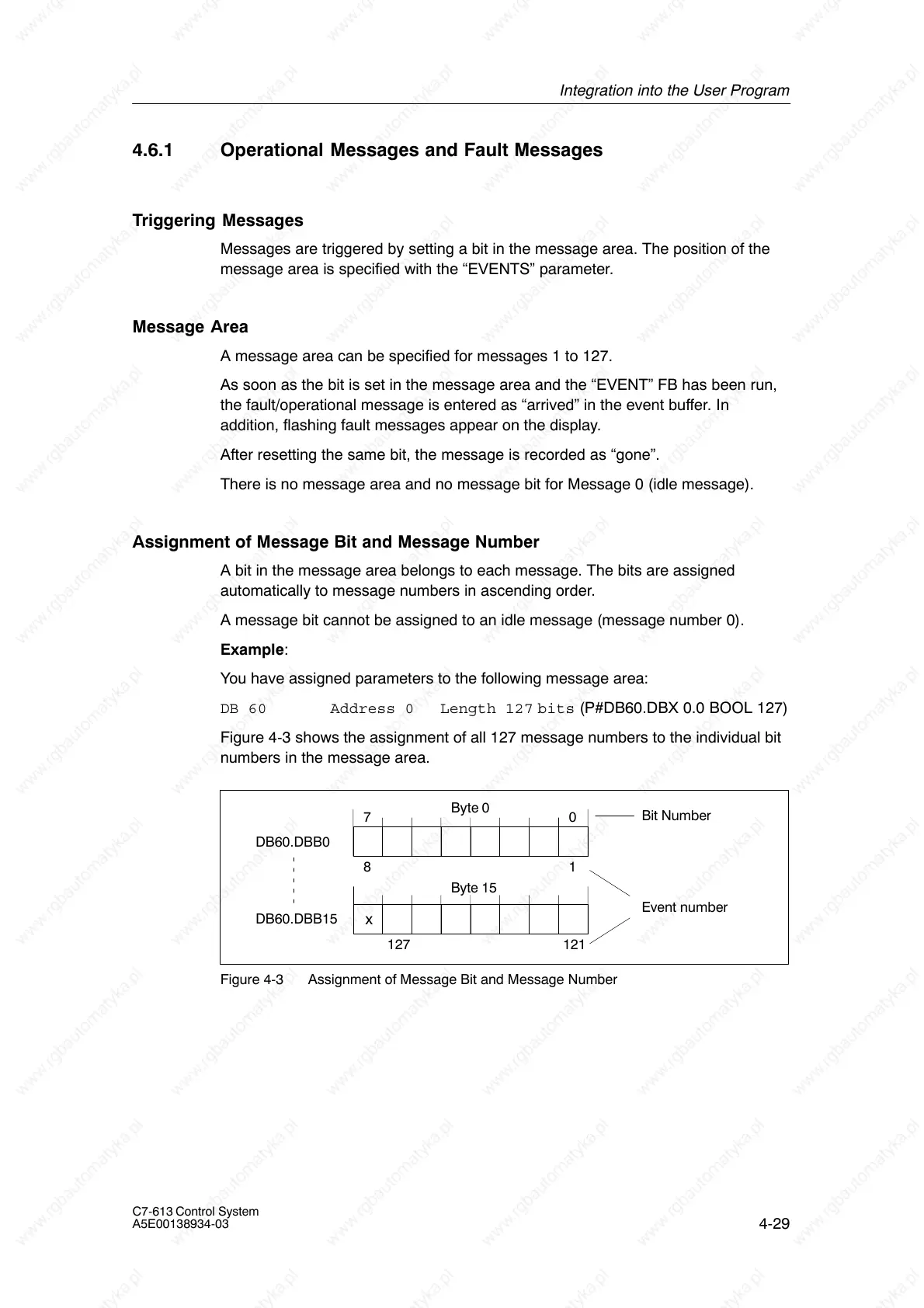

Assignment of Message Bit and Message Number

A bit in the message area belongs to each message. The bits are assigned

automatically to message numbers in ascending order.

A message bit cannot be assigned to an idle message (message number 0).

Example:

You have assigned parameters to the following message area:

DB 60 Address 0 Length 127 bits (P#DB60.DBX 0.0 BOOL 127)

Figure 4-3 shows the assignment of all 127 message numbers to the individual bit

numbers in the message area.

127

1

DB60.DBB0

8

DB60.DBB15

7

0

121

Byte 0

Event number

Byte 15

Bit Number

x

Figure 4-3 Assignment of Message Bit and Message Number

Loading...

Loading...