4

4.2 Process data (PZD area)

4-117

E Siemens AG 2013 All Rights Reserved

SIMODRIVE POSMO A User Manual (POS1) – 08/2013 Edition

4.2.4 Example: The drive should traverse with n–set using the control signals

The drive should be operated with n = 500 rpm (gearbox output) in

n–set mode.

Assumptions for the slave:

S The drive has been completely commissioned, is

connected to PROFIBUS–DP and is ready.

S PROFIBUS node address = 12

Assumptions for the master:

S The DP master is a SIMATIC S7 (CPU: S7–315–2–DP)

S Hardware configuration

– PROFIBUS node address = 12

– Part I address O address

PKW 256 – 263 256 – 263 (not drawn in the example)

PZD 264 – 267 264 – 267

Prerequisites:

S Gearbox ratio is entered in P3

S P880 = 4096

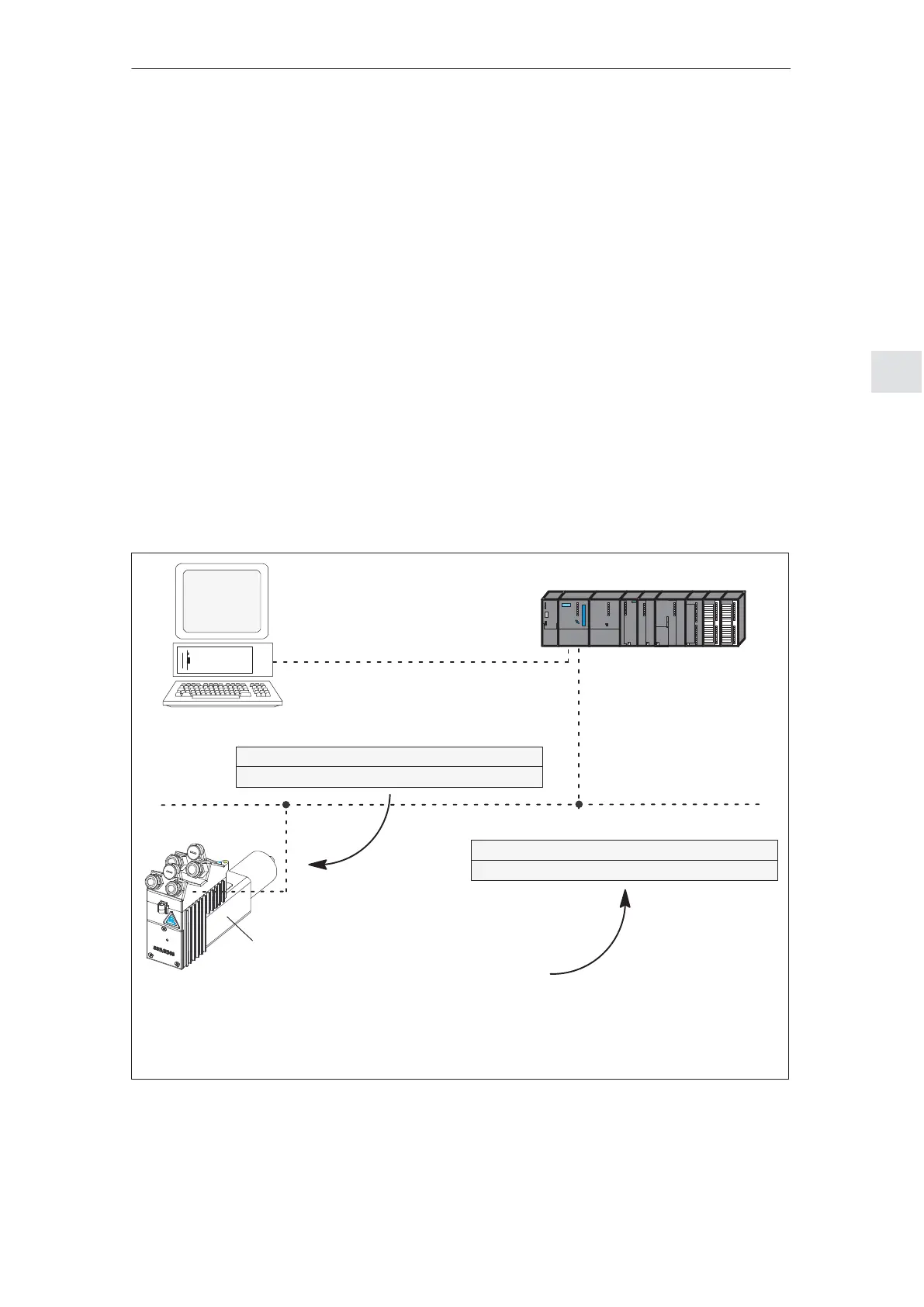

DP slave

POSMO A

PROFIBUS–DP

SIMATIC S7–300 (CPU: S7–315–2–DP)

MPI

Output signals at

the DP slave

Input signals at

the DP slave

Control signals

STW

PAW 264 = xxxx xxxx x111 1111

Status signals

ZSW

PG/PC

PEW 264 = 1010 0111 0011 0111

PEW 266 = 0000 0001 1111 0100

PAW Peripheral output word

PEW Peripheral input word

STW, ZSW Control word, Status word

PAW 266 = 0000 0001 1111 01000

Fig. 4-4 Example: Drive should traverse with n–set

Example:

Operating the

drive with

n–set

4 Communications via PROFIBUS–DP

02.9905.03

Loading...

Loading...