2

2.5 Gearbox selection

2-61

E Siemens AG 2013 All Rights Reserved

SIMODRIVE POSMO A User Manual (POS1) – 08/2013 Edition

2.5 Gearbox selection

2.5.1 Gearboxes for SIMODRIVE POSMO A – 75 W

For SIMODRIVE POSMO A –75 W, the following gearboxes can be

selected and used according to Table 2-4:

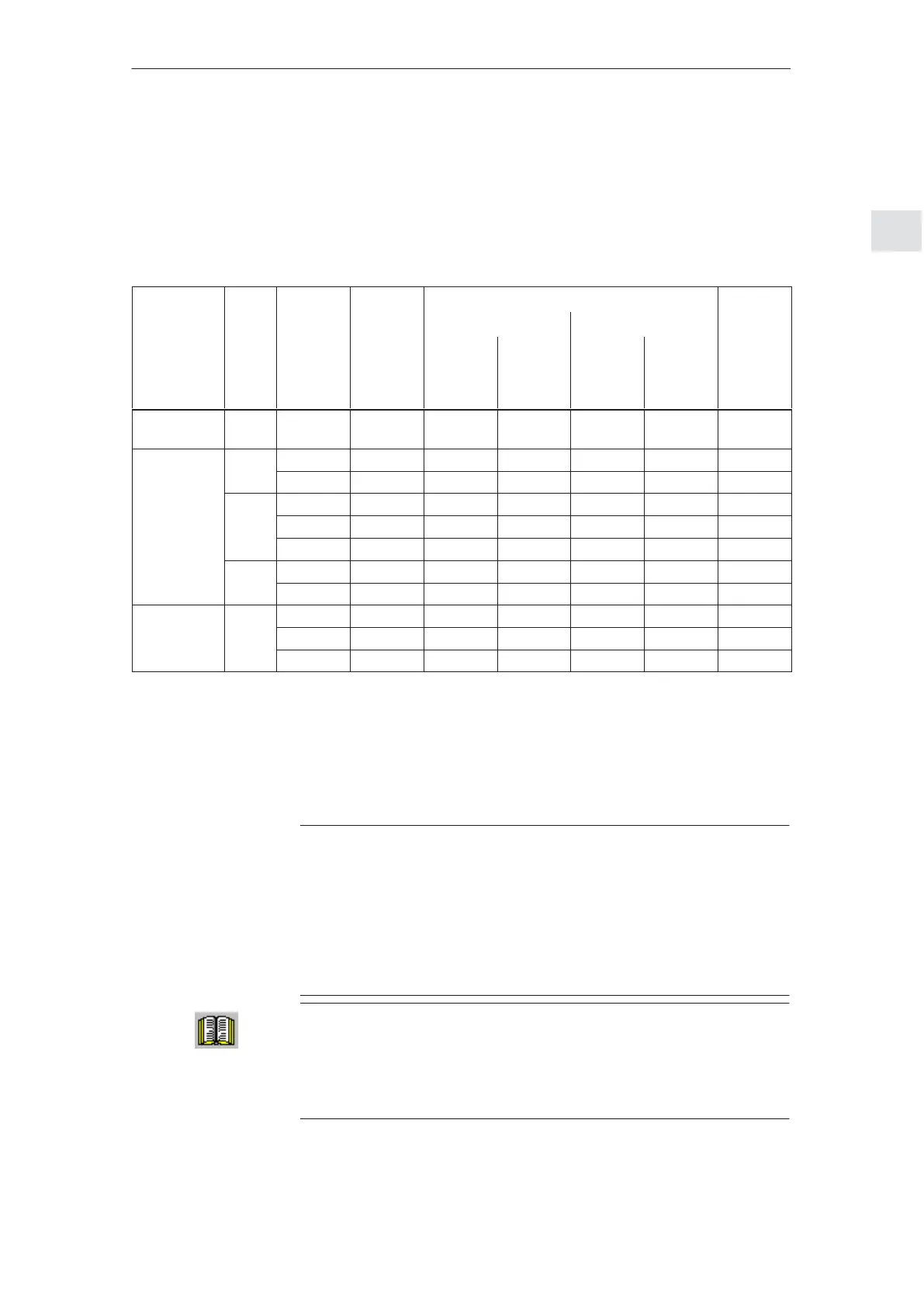

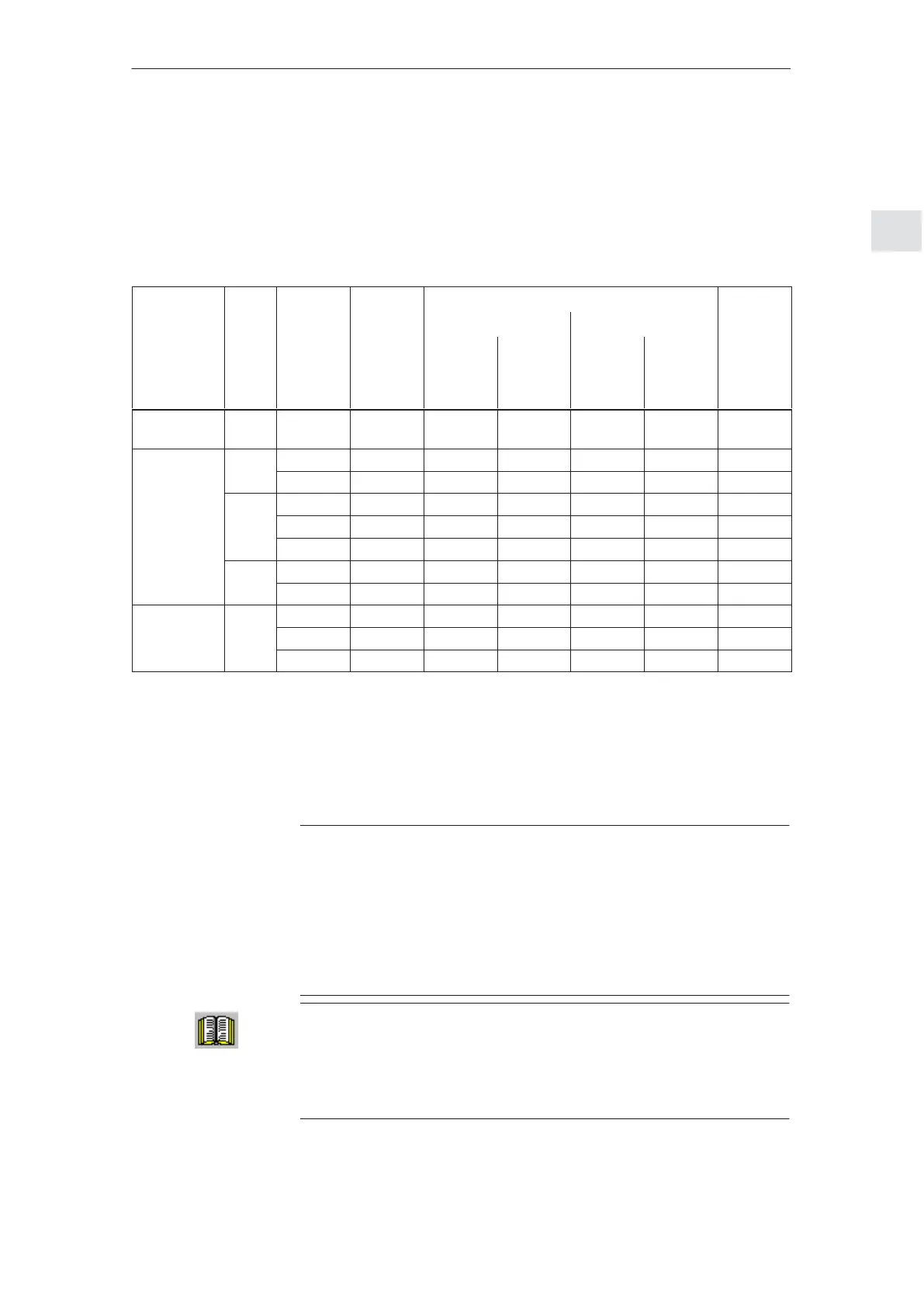

Table 2-4 System data, modular gearbox with planetary/worm gearboxes

Gearbox

Stage

Step–

Effi-

Torque Rated

Permissible

1)

Available

S1 briefly S1 S3

25 %

1 min

n

(S1)

i

Gearbox Gearbox

[Nm] [Nm] [Nm] [Nm] [rpm]

Without

gearboxes

– – – – – 0.18 0.36 3300

4.5 0.85 1.2 2.4 0.7 1.4 733

8 0.85 1.2 2.4 1.2 2.4 413

20.25 0.72 8 16 2.6 5.2 163

Planetary

2

36 0.72 8 16 4.7 9.3 92

50 0.72 8 16 6.5 13.0 66

126.5625 0.61 24 48 13.9 27.8 26

162 0.61 24 48 17.8 35.6 20

5 0.70 2 4 0.6 1.3 660

Worm

1

24 0.50 3.5 7 2.2 4.3 138

75 0.25 4 8 3.4 6.8 44

1) The specified permissible gearbox torque may not be exceeded.

Gearboxes can be briefly loaded (1 – 2 s when starting) with higher torques up to a maximum of twice the

continuous torque without causing permanent damage (but this does have a negative impact on the

gearbox lifetime). The gearbox could be destroyed if this limit is exceeded.

The current limits of the positioning motor (P16 and P28) are preset in the factory to prevent destruction

by the torque produced by the motor.

2) Notice: If the worm gear has to be rotated due to the mechanical design, then the mounting screws must

be subsequently tightened to a torque of 2 Nm and secured using Loctite 274. No warranty is accepted

for damage caused by incorrect changes.

3) Torsional play < 1°

Notice

The factory default setting of the parameters P16 and P28 must not be

increased.

Forced rotation acceleration or delay from the outside is permitted only

within the scope of permissible torques.

Due to the run–up time of the gearbox, elevated currents may occur

when commissioning for the first time (grease distribution in the

gearbox).

Reader’s note

Additional gearbox data ––> refer to Chapter 2.6.1

Dimension drawings of

motors and gearboxes ––> refer to Chapter C.1

Gearbox–dependent parameters ––> refer to Chapter 5.6.3

Modular gearbox,

75 W motor

2 Installing and Connecting–Up

02.9908.0410.07

Loading...

Loading...