Do you have a question about the Siemens SIMOTION D4x5-2 and is the answer not in the manual?

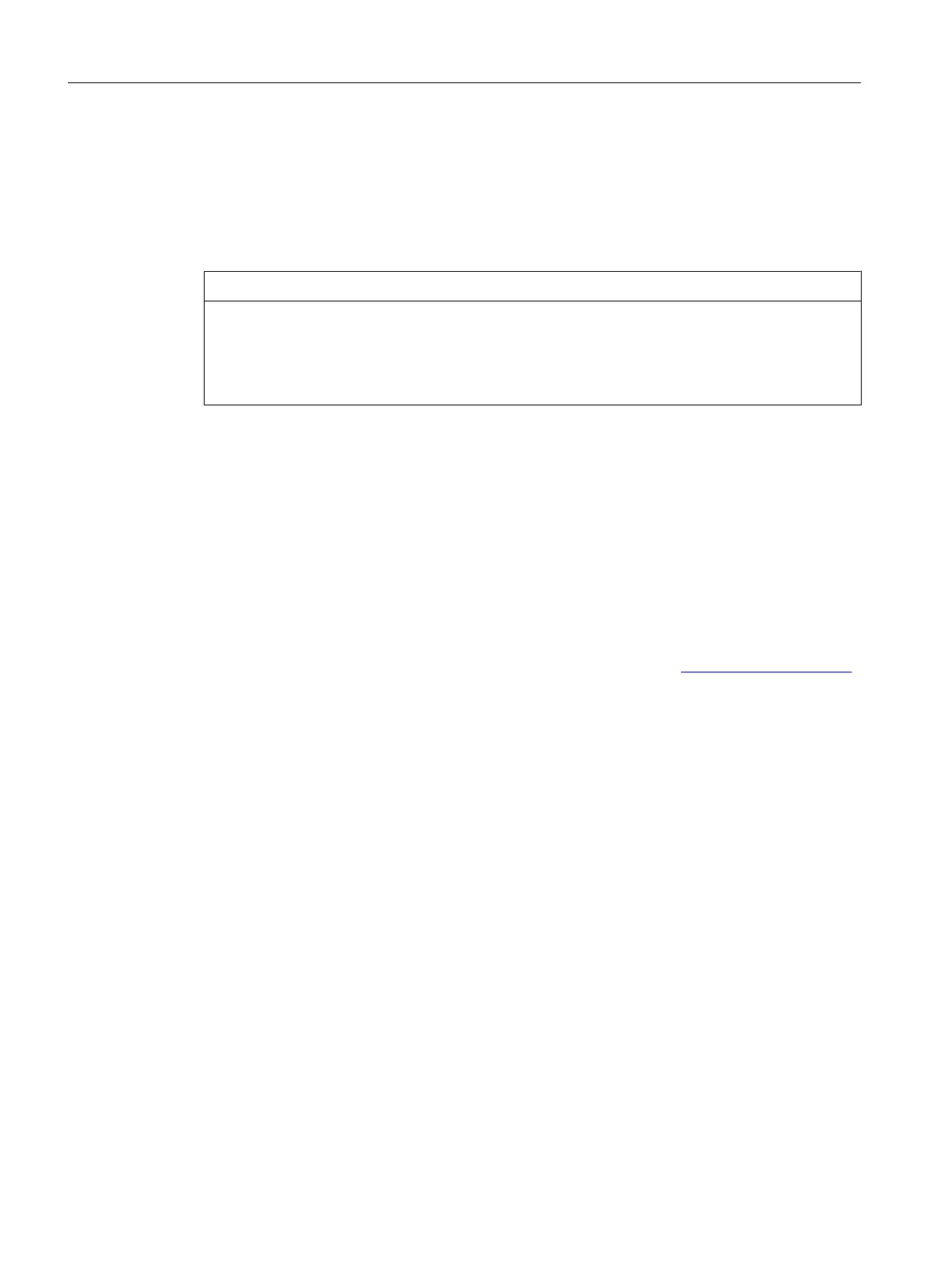

| Power Supply | 24 V DC |

|---|---|

| Control Unit Type | SIMOTION D4x5-2 |

| Product type designation | SIMOTION D4x5-2 |

| Communication Interfaces | PROFIBUS, PROFINET, Ethernet |

| Programming Language | ST (Structured Text), LAD (Ladder Diagram), FBD (Function Block Diagram) |

| Processor | Intel |

| Ethernet Ports | Integrated |

| USB Ports | Integrated |

| DisplayPort | 1 |

Provides fundamental safety instructions covering EMF, ESD, security, software manipulation, and residual risks.

Provides safety information specific to the SIMOTION D4x5-2, including hazardous voltage and electric shock.

Provides instructions for installing the SIMOTION D4x5-2, including mounting aids and methods.

Details protective conductor connection, equipotential bonding, and EMC considerations.

Covers safety rules, standards, mains voltage, and connecting the power supply.

Explains DRIVE-CLiQ wiring, components, and topology.

Covers PROFIBUS connection components, cables, lengths, rules, and topology.

Covers wiring PROFINET IO, mixed operation of IRT and RT, and cable/connector types.

Explains wiring Ethernet, cable characteristics, recommended cables, and autocrossing.

Lists requirements for initial commissioning, including system wiring and PG/PC connection.

Specifies the necessary SIMOTION SCOUT version and configuration details.

Guides through creating a SIMOTION project and configuring communication via PROFIBUS and Ethernet.

Covers general information, operating modes, address assignment, and cycle clocks for PROFIBUS DP.

Covers PROFINET IO communication cycles, IRT, RT, sync domains, and controller/device roles.

Details properties of Ethernet interfaces, communication, IP address setting, and routing.

Lists requirements and important functions for project handling and commissioning.

Guides through offline project creation and configuration steps.

Guides through online configuration steps like establishing connections and automatic configuration.

Provides overview, basic principles, power-up, online functions, and configuration preparation for CX32-2.

Guides on testing a configured drive using the drive control panel.

Covers SIMOTION engineering, creating axes with wizards, and testing axes.