Removing

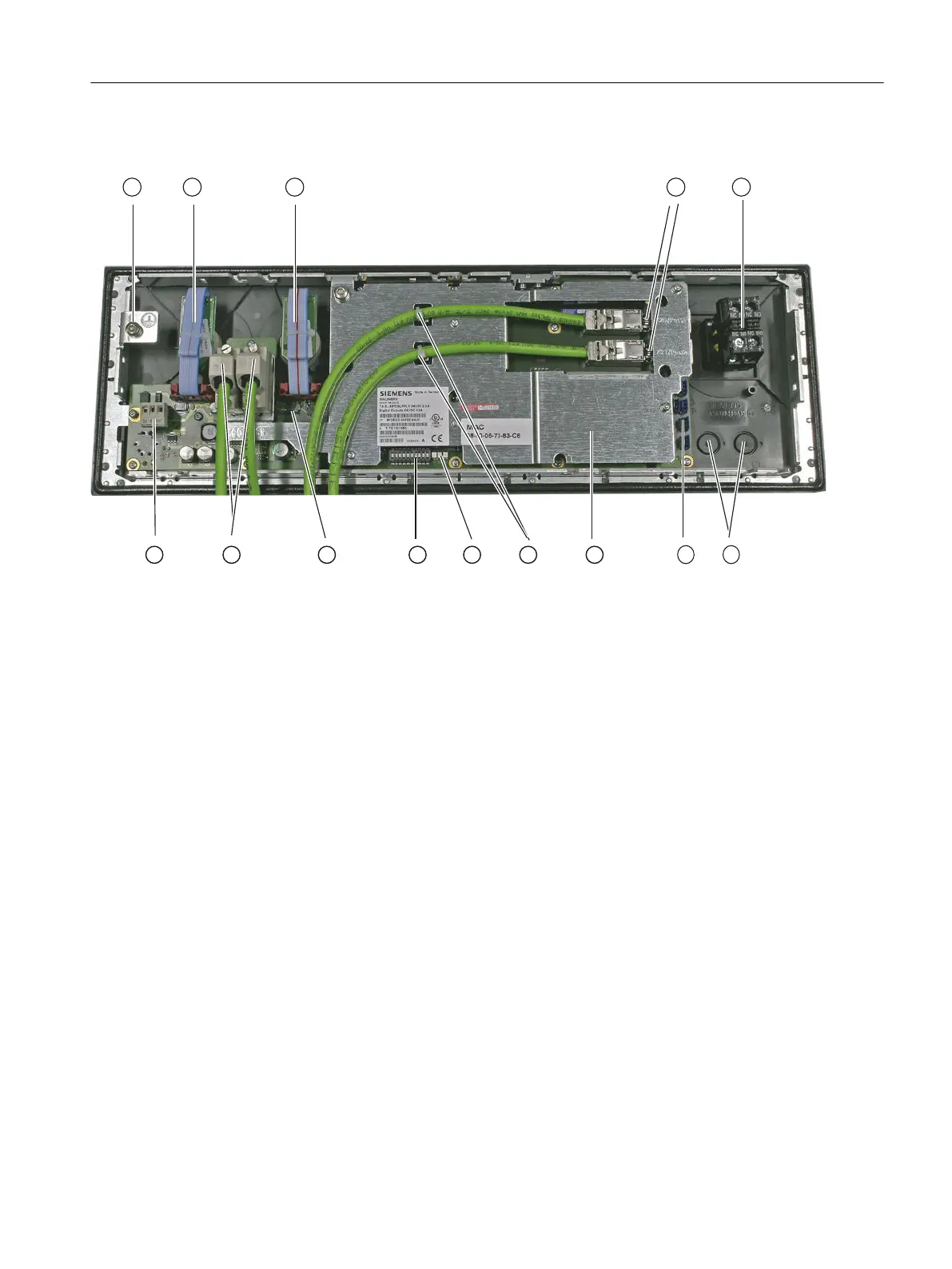

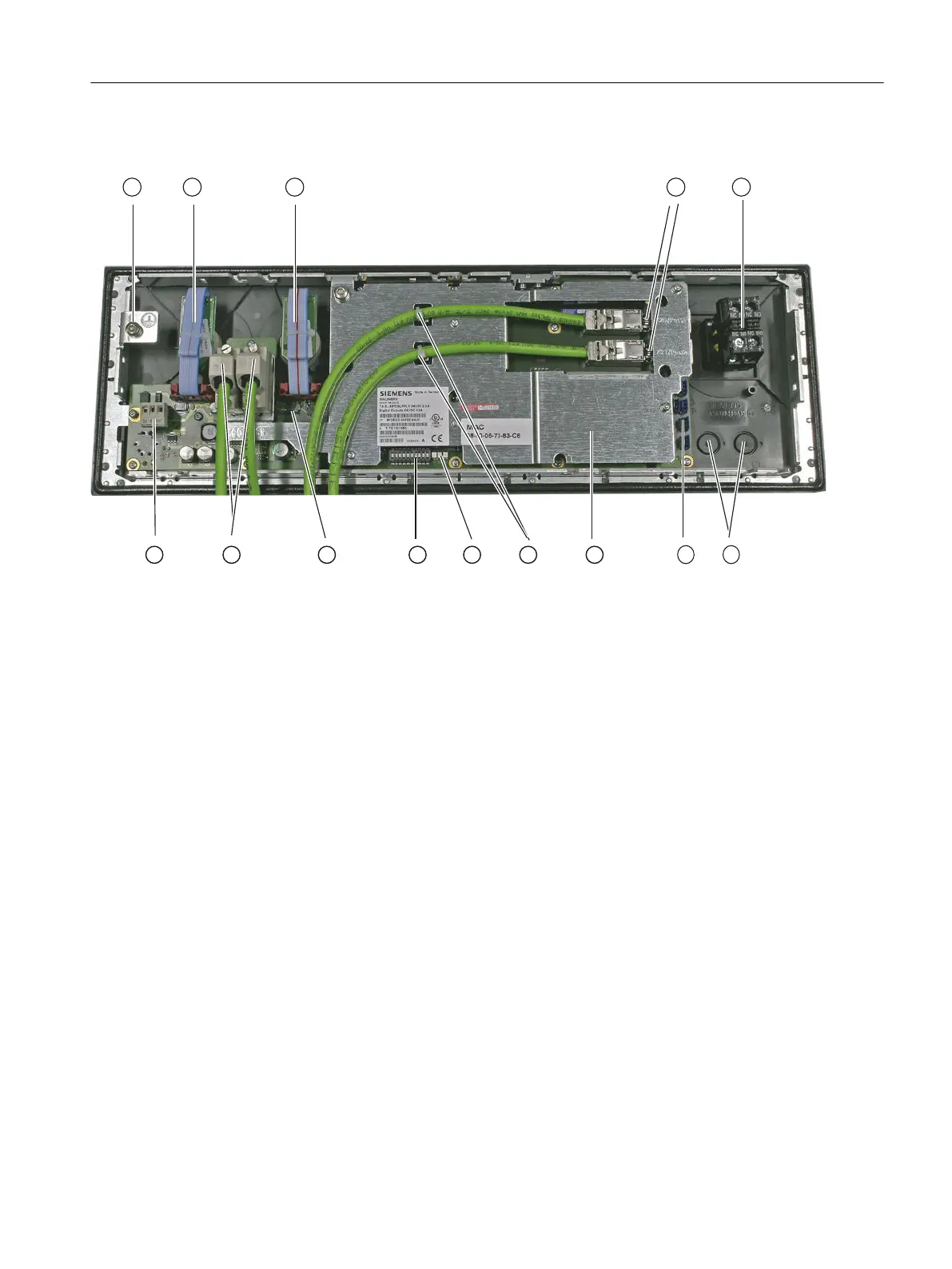

① Ground terminal

② X30 Feedrate override

③ X31 Spindle override

④ X20 Port 1: Connection: PLC I/O interface based on PROFINET

X21 Port 2: Connection: PLC I/O interface based on PROFINET

⑤ Slot for Emergency Stop

⑥ Mounting slots for additional command devices

⑦ Customer-specific inputs and outputs

⑧ Cover plate

⑨ Ethernet cable strain relief

⑩ LED

⑪ S2 Switch for setting the MCP address

⑫ S1 Switch for setting the handwheel signal type

⑬ X60 Handwheel connection

X61 Reserved

⑭ X10 Power supply interface

Figure 4-11 MCP 483C PN rear side

Procedure:

1. Switch-off the control: Completely switch off the system. Check that the system is in a no-

voltage condition and is locked-out so that it cannot be switched on again without the

appropriate authorization.

2. Access the operator panel/control cabinet in which the machine control panel is located.

3. Using a multimeter, check the X10 power supply to ensure that the system really is in a no-

voltage condition.

Service cases - hardware

4.5 Machine control panels

Software and hardware

Service Manual, 08/2018, 6FC5397-5DP40-6BA1 101

Loading...

Loading...