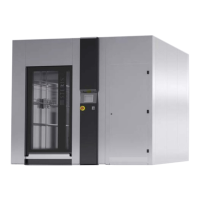

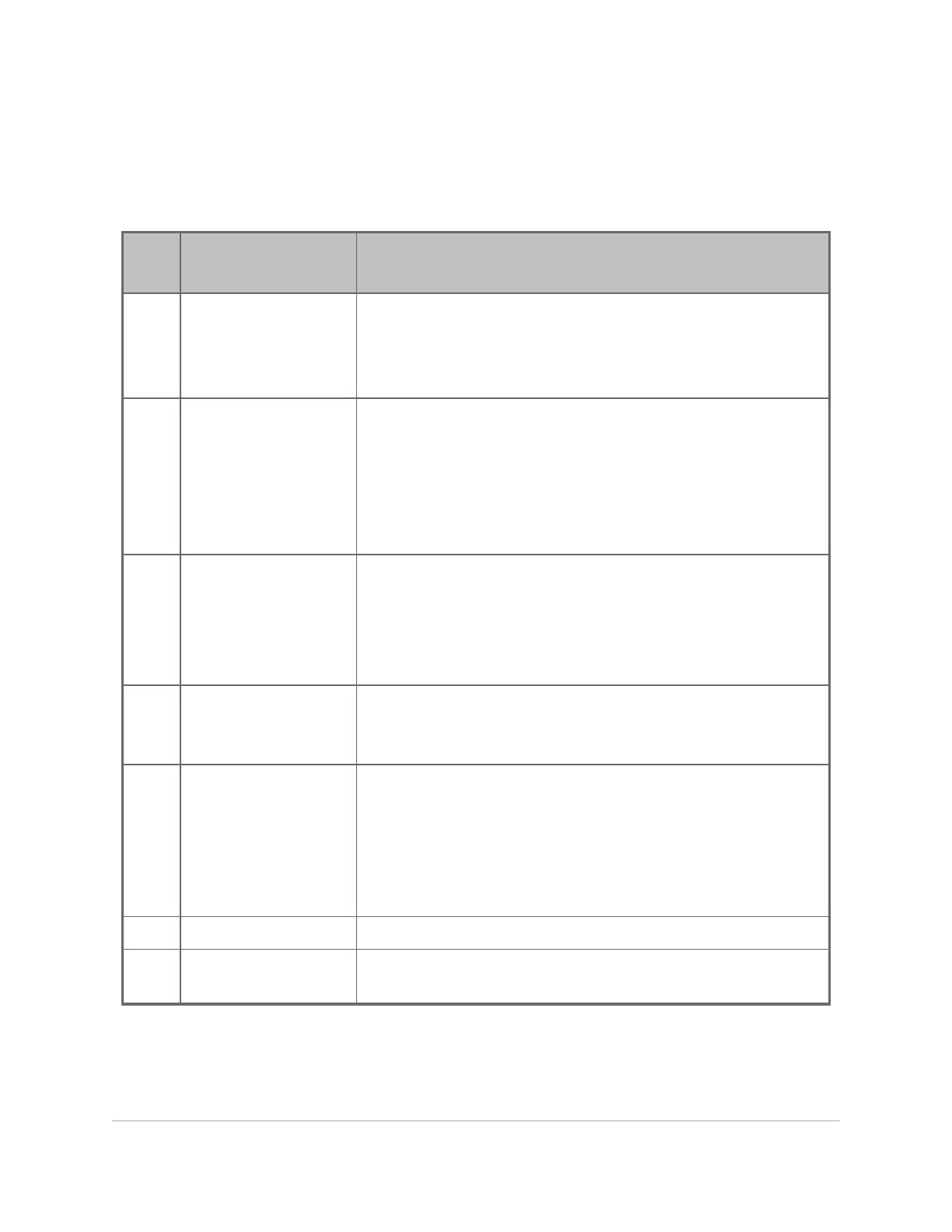

11.1 Diagnosing Error Codes

Use the table below to diagnose and remedy error codes reported on the display.

Error

Code

Error Message

Description

1 Mains power

removed

Mains supply to equipment was interrupted during a cycle.

Turn equipment back on and repeat cycle.

If problem persists have electrician or qualified technician

inspect electrical connection.

2 Chamber overflow

Make sure drain is not blocked.

Make sure instruments are not blocking drain.

Make sure non-foaming chemical is being used.

Make sure water pressure is not too high.

If problem persists, contact supplier to arrange a qualified

technician inspection.

3 Drain timeout

Make sure filter is not clogged.

Make sure instruments are not blocking drain.

Make sure drain hose is not kinked or restricted, and that

site drain is not blocked.

Make sure non-foaming chemical is being used.

4 Chamber

temperature sensor

mismatch

Repeat cycle.

If problem persists, contact supplier to arrange a qualified

technician inspection.

5 Chamber fill timeout

Make sure water inlet hoses are connected and not kinked

or blocked.

Make sure site water supply is on.

Check equipment and water connections for leaks.

If equipment is leaking, contact supplier to arrange a

qualified technician inspection.

6 Chamber opened

Make sure lid is closed.

7 Temperature set

point not maintained

Repeat cycle. If problem persists, contact supplier to

arrange a qualified technician inspection.

Table 11.1 Error Codes and Remedy Actions

90 TROUBLESHOOTING

InnoWave Unity & Unity 20 Operator Manual

Loading...

Loading...