Troubleshooting Guides

600 Series

(Prior to #1810000)

8-14

#3756270 - Revision B - January, 2006

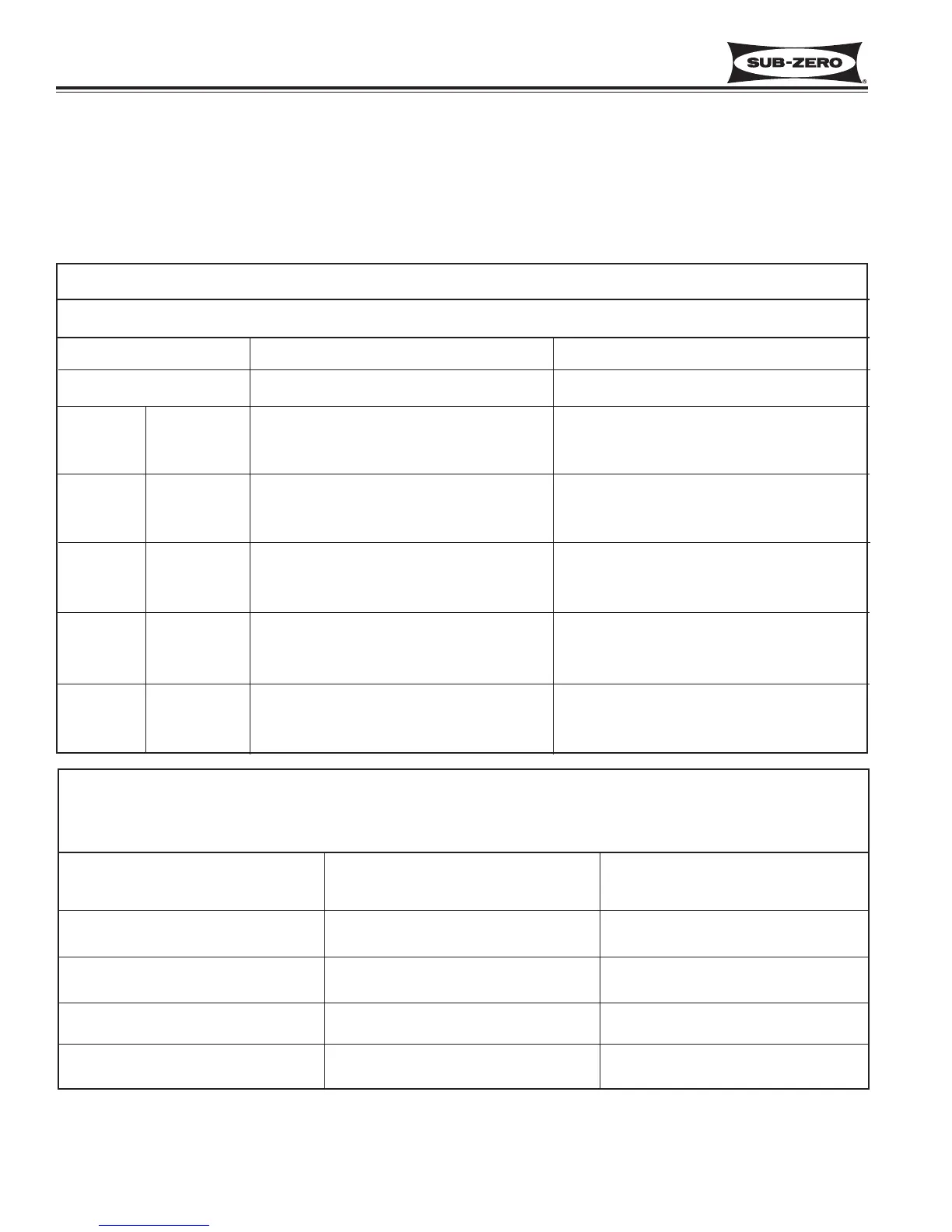

SEALED SYSTEM TROUBLESHOOTING INFORMATION

NOTE: Before troubleshooting the sealed system, be sure to see Page 8-2 and go through the preceding General

Troubleshooting Guide.

NOTE: Whenever entering the sealed system, always use solder-on process valves.

NOTE: Whenever servicing the sealed system, the filter-drier must be replaced.

Normal Operating Pressures

MODEL NORMAL LOW SIDE PRESSURE NORMAL HIGH SIDE PRESSURE

601R 18 psi to 39 psi 90 psi to 100 psi

601F 1 psi to 14 psi 90 psi to 100 psi

611 Refrig. 16 psi to 36 psi 90 psi to 100 psi

Freezer 1 psi to 15 psi 90 psi to 100 psi

632 Refrig. 9 psi to 35 psi 90 psi to 100 psi

Freezer 1" Vac to 8 psi 90 psi to 100 psi

642 Refrig. 9 psi to 35 psi 90 psi to 100 psi

Freezer 1" Vac to 8 psi 90 psi to 100 psi

650 Refrig. 6 psi to 34 psi 90 psi to 100 psi

Freezer 2" Vac to 9 psi 90 psi to 100 psi

690 Refrig. 16 psi to 36 psi 90 psi to 100 psi

Freezer 2 psi to 10 psi 90 psi to 100 psi

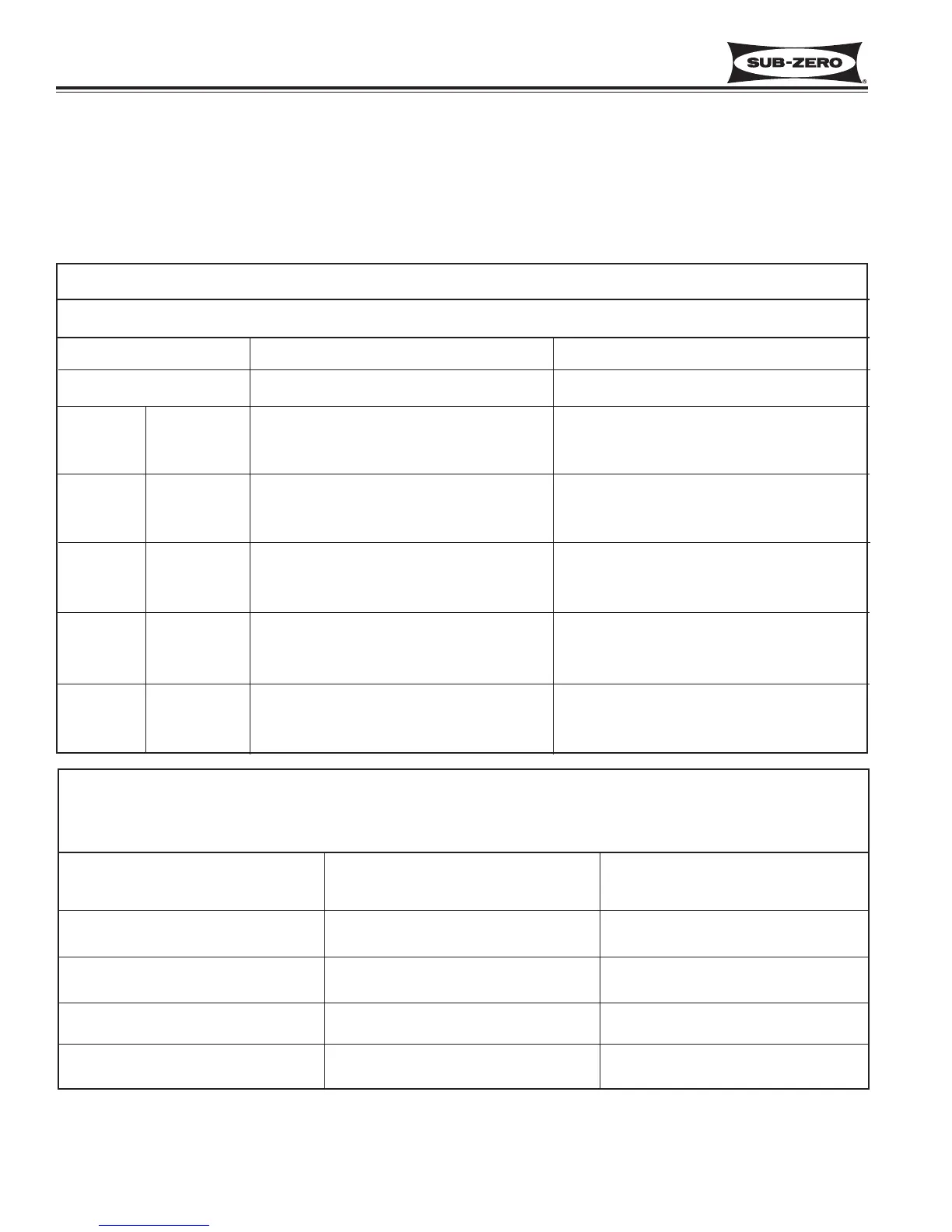

Pressure Indications

IF LOW SIDE PRESSURE IS & HIGH SIDE PRESSURE IS POSSIBLE PROBLEM IS

NORMAL NORMAL MECHANICAL

(See General Troubleshooting Guide)

LOW LOW Leak

LOW HIGH Restriction

HIGH LOW Inefficient Compressor

HIGH HIGH Over Charge

Loading...

Loading...