Engine Mechanical: 1D-45

5) Cool down the new valve guides in a freezer for

about one hour and heat the cylinder head to 100 –

150 °C (212 – 302 °F) with a hot plate.

CAUTION

!

Do not use a burner to heat the valve guide

hole to prevent cylinder head distortion.

6) Apply engine oil to each valve guide and valve guide

hole.

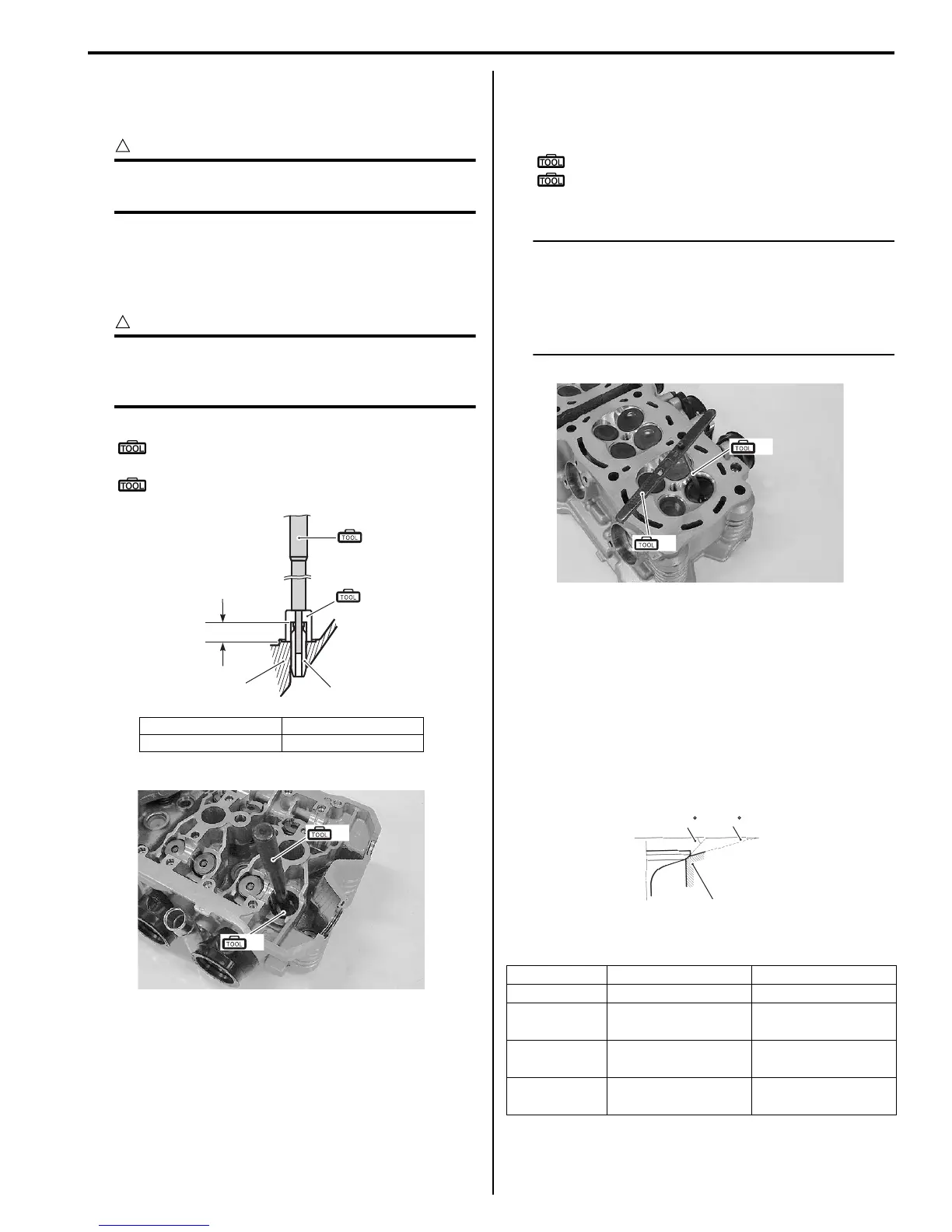

7) Drive the guide into the guide hole using the valve

guide installer.

CAUTION

!

Failure to oil the valve guide hole before

driving the new guide into place may result in

a damaged guide or head.

Special tool

(A): 09916–43211 (Valve guide remover/

installer)

(D): 09916–43220 (Attachment)

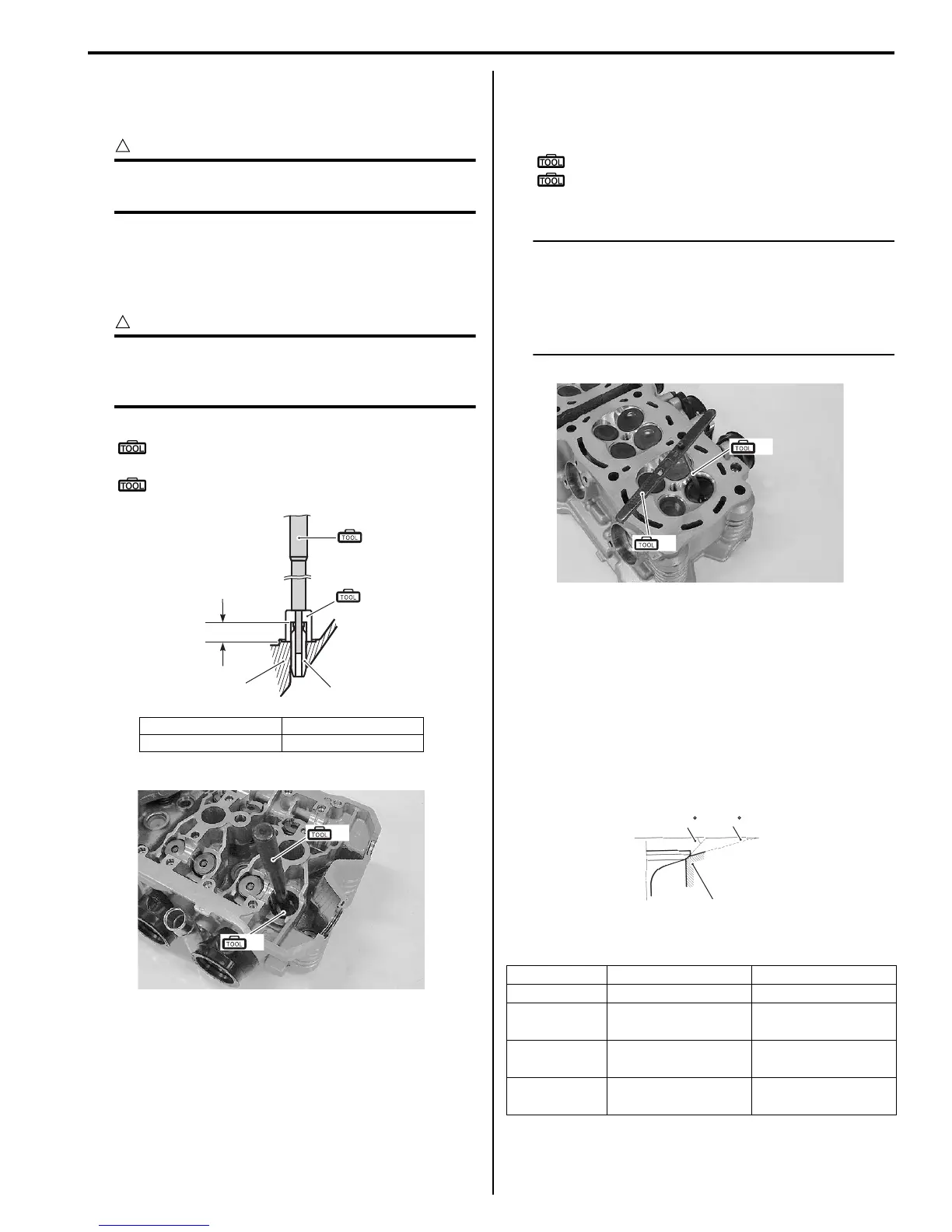

8) After installing the valve guides, refinish their guiding

bores using the reamer. Be sure to clean and oil the

guides after reaming.

Special tool

(C): 09916–34542 (Reamer handle)

(E): 09916–33210 (Valve guide reamer (4.5

mm))

NOTE

• Be sure to cool down the cylinder head to

ambient air temperature.

• Insert the reamer from the combustion

chamber and always turn the reamer

handle clockwise.

9) Reassemble the cylinder head. Refer to “Cylinder

Head Disassembly and Assembly (Page 1D-38)”.

10) Install the cylinder head assembly. Refer to “Engine

Top Side Assembly (Page 1D-26)”.

Valve Seat Repair

B817H21406030

The valve seats (1) for both the intake and exhaust

valves are machined to two different angles. The seat

contact surface is cut at 45°.

1. Cylinder head “a”: 15.0 mm (0.591 in)

2. Valve guide

“a”

(A)

(D)

1

2

I717H1140113-01

(A)

(D)

I718H1140128-01

Intake Exhaust

Seat angle 15°/45° 15°/45°

Seat width

0.9 – 1.1 mm

(0.035 – 0.043 in)

←

Valve

diameter

23 mm

(0.91 in)

20 mm

(0.79 in)

Valve guide

I.D.

4.500 – 4.512 mm

(0.1772 – 0.1776 in)

←

(E)

(C)

I718H1140129-01

1

45 15

IN. & EX.

I717H1140222-01

Loading...

Loading...