1G-14 Fuel System:

Assembly

Refer to “Fuel Mesh Filter Inspection and Cleaning

(Page 1G-14)”.

Assemble the fuel tank pump in the reverse order of the

disassembly. Pay attention to the following points:

CAUTION

!

• To prevent fuel leakage, each O-ring must

be replaced with a new one.

• Apply engine oil lightly to each of the O-

rings.

• Connect all wiring couplers securely so as not to

cause contact failure.

Fuel Mesh Filter Inspection and Cleaning

B817H21706015

Inspect the fuel mesh filter in the following procedures:

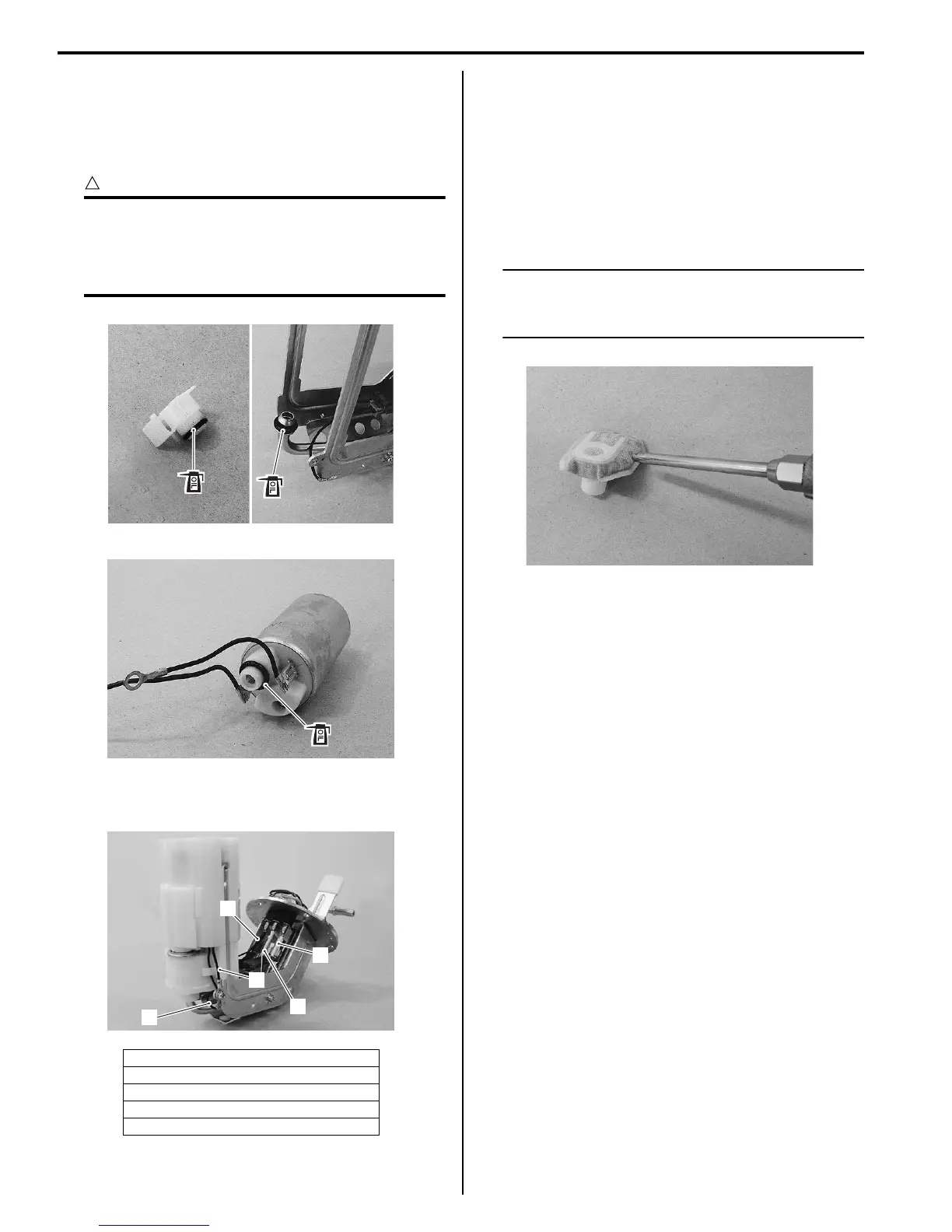

1) Remove the fuel mesh filter. Refer to “Fuel Pump

Disassembly and Assembly (Page 1G-12)”.

2) If the fuel mesh filter is clogged with foreign particles,

it hinders smooth gasoline flow resulting in loss of

engine power. Such a filter should be cleaned by

blowing with compressed air.

NOTE

When the fuel mesh filter is dirtied

excessively, replace the fuel filter cartridge

with a new one.

3) After finishing the fuel mesh filter inspection, reinstall

the fuel mesh filter. Refer to “Fuel Pump

Disassembly and Assembly (Page 1G-12)”.

Fuel Hose Inspection

B817H21706016

Refer to “Fuel Line Inspection in Section 0B (Page 0B-

12)”.

Fuel Injector / Fuel Delivery Pipe / T-joint

Removal and Installation

B817H21706017

Refer to “Throttle Body Disassembly and Assembly in

Section 1D (Page 1D-11)”.

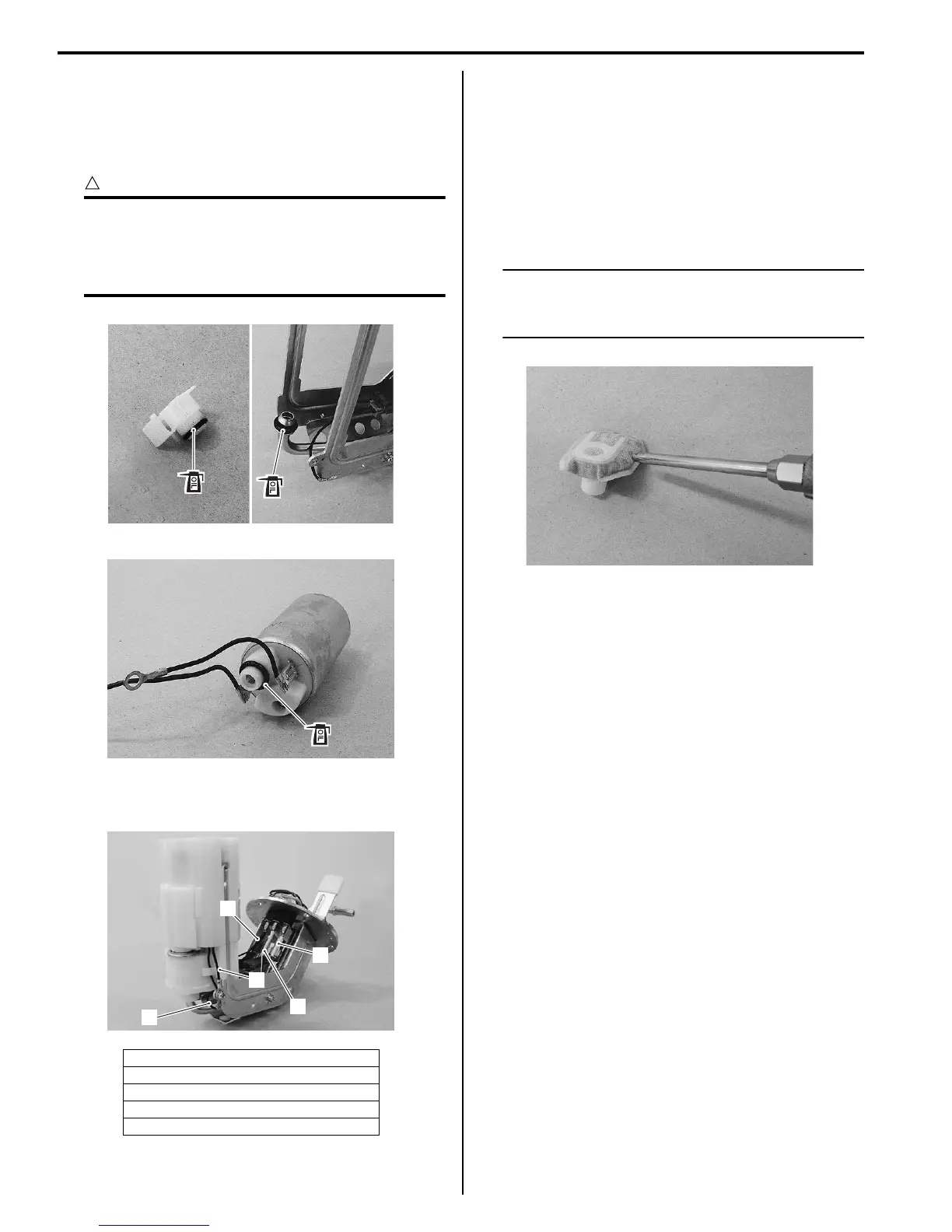

1. Fuel pump (+) lead wire (BI)

2. Fuel level thermistor lead wire (W)

3. Fuel level gauge (+) lead wire (BI)

4. Fuel pump (–) lead wire (B)

5. Fuel level gauge (–) lead wire (B)

I717H1170017-01

I718H1170039-01

1

2

3

4

5

I718H1170037-01

I718H1170003-01

Loading...

Loading...