5-30

MAINTENANCE

INSPECTING AND ADJUSTING THE

V-BELT

Stop the engine and allow the machine to

cool down before performing

maintenance.

• The engine, muffler, radiator, hydraulic

lines, sliding parts and many other parts

of the machine are hot immediately after

the engine is stopped. Touching these

parts will cause burns.

• Before performing maintenance on the

top of the machine, clean the place you

will work on and observe the following

to prevent falling.

· Do not spill oil or grease.

· Do not leave tools scattered around.

· Watch your step when walking.

• Never jump down from the machine.

Use the steps and handrails when

climbing up and down the machine, and

always support your body at three

points with your hands and feet.

IMPORTANT: The loose belts could result

in bad battery charge, overheat of engine

or early wear of belt. Too tight belts could

damage the water pump or bearing and

belt used to drive the alternator.

IMPORTANT: Do not let any oil or grease

get on the belt.

Inspection

1. Open the engine hood and the

maintenance cover.

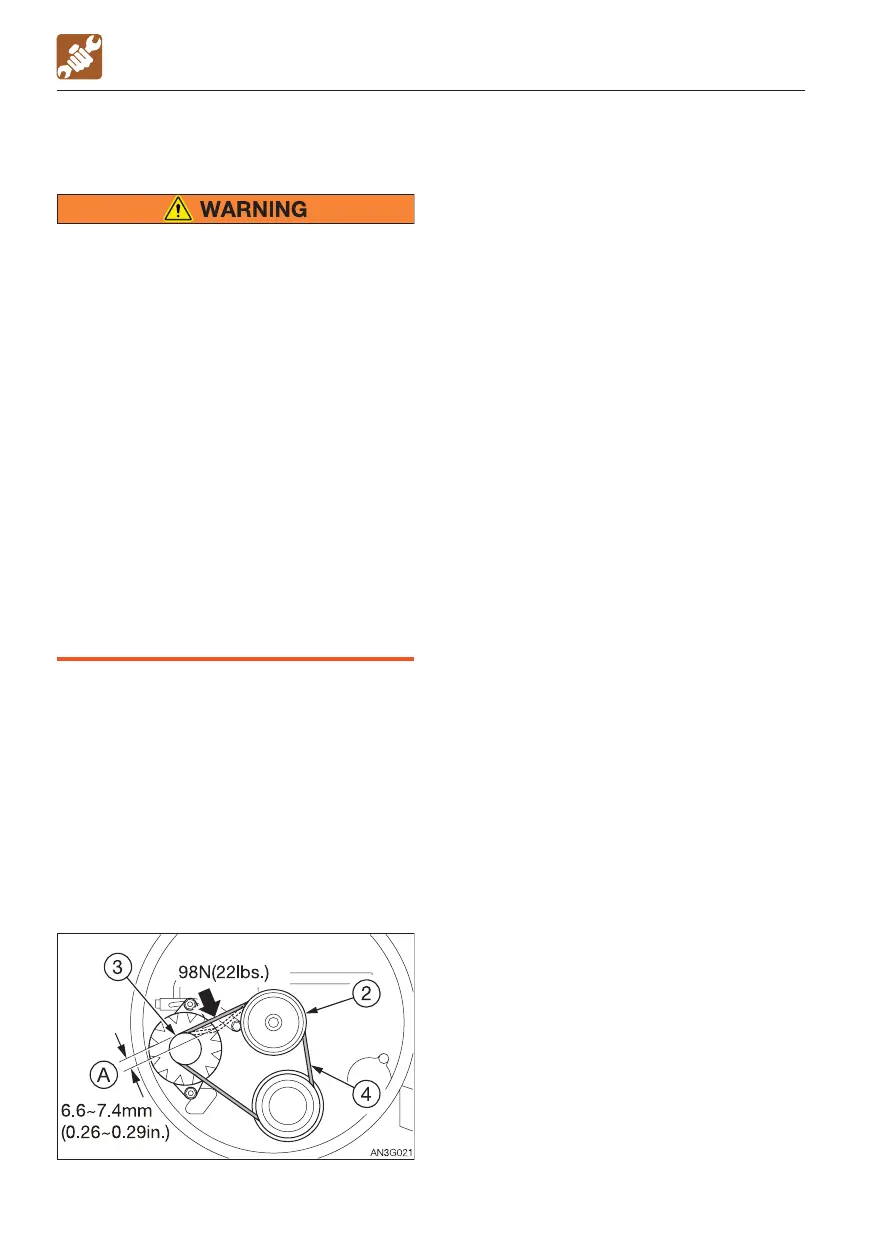

2. Press the midpoint of the V-belt between

the pulley (2) and alternator pulley (3) to

check the tension. (approx. 98 N or 22

lbs.).

The slack (A) should be 6.6 to 7.4 mm

(0.26 to 0.29 in).

3. Inspect the V-belt (4) and replace if it is as

follows.

· There are cuts or cracks.

· The belt is worn and touches the bottom

of the V groove in the pulley.

· The belt stretched too loose to be

adjusted.

AFTER THE INITIAL 50 HOURS (ONLY FOR NEW MACHINES)

Loading...

Loading...