5-74

MAINTENANCE

ADJUSTING THE GAP BETWEEN THE

BUCKET AND ARM (IF EQUIPPED)

• Before performing maintenance or

repairs under the machine, lower all

working equipment to the ground or in

the lowermost position.

• To prevent unexpected movement,

securely block the working equipment

when adjusting the gap.

1. Lower the bucket to the ground in a stable

position as shown in the figure above.

2. Slew the upperstructure slightly to the left

and lightly press the arm to the left side of

the bucket (the side without an adjuster).

3. Set the safety lock lever to the lock

position and stop the engine.

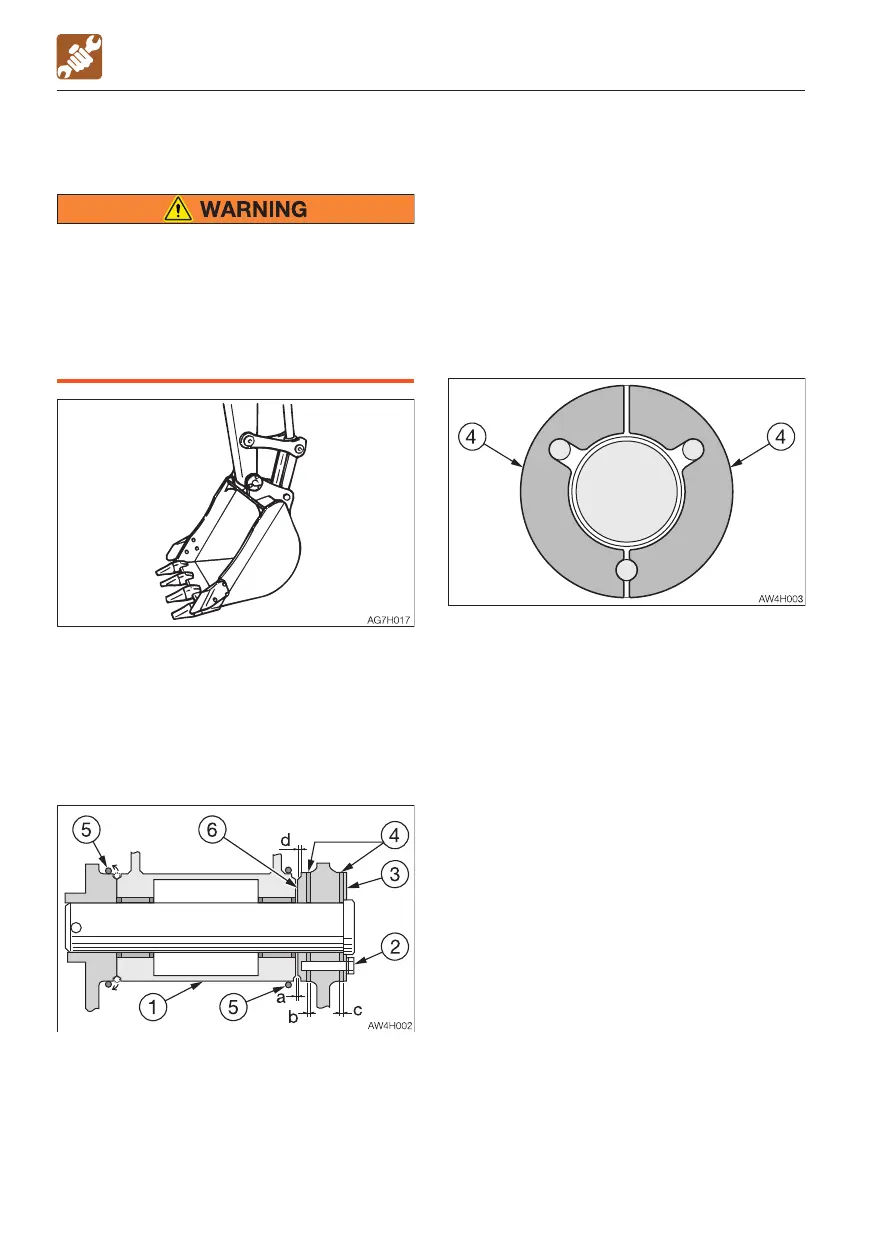

4. Slightly loosen the 3 bolts (2) (using a 22

mm (0.87 in) wrench) and remove the

shims (4) from “gap c” between the blade

(3) and bucket. The shims (4) are in two

parts and can be removed easily when the

bolts are slightly loosened by sticking a

screwdriver in the seam between the left

and right shims.

5. Move the O-ring (5) to bring the gap (a)

into view and measure the width of the

gap (a).

6. Press the head of the bolts (2) with a finger

to eliminate gap (a). This increases gap (b).

Insert the shims removed above into gap

(b), using as many shims as can be

inserted easily.

7. Set the remaining shims back in gap (c),

then tighten the bolts.

Tightening torque : 83 N·m (61.5 ft-lb).

This completes the adjustment.

Note: The proper total number of shims for

gaps (b) and (c) is 6 x 2 = 12. If you forget to

set the shims remaining in step 7 above

back in gap (c), the tip of bolts (2) will extend

past the boss (6). This may damage the boss

at the arm’s tip or cause the bolt to break. If

the end face of boss (6) wears and the width

of the groove (d) for the O-ring reaches 5

mm (0.2 in), replace boss (6) with a new one.

WHEN REQUIRED

Loading...

Loading...