5-53

MAINTENANCE

EVERY 500 HOURS

2. Place a pan under the pre-fuel filter (1) to

catch fuel.

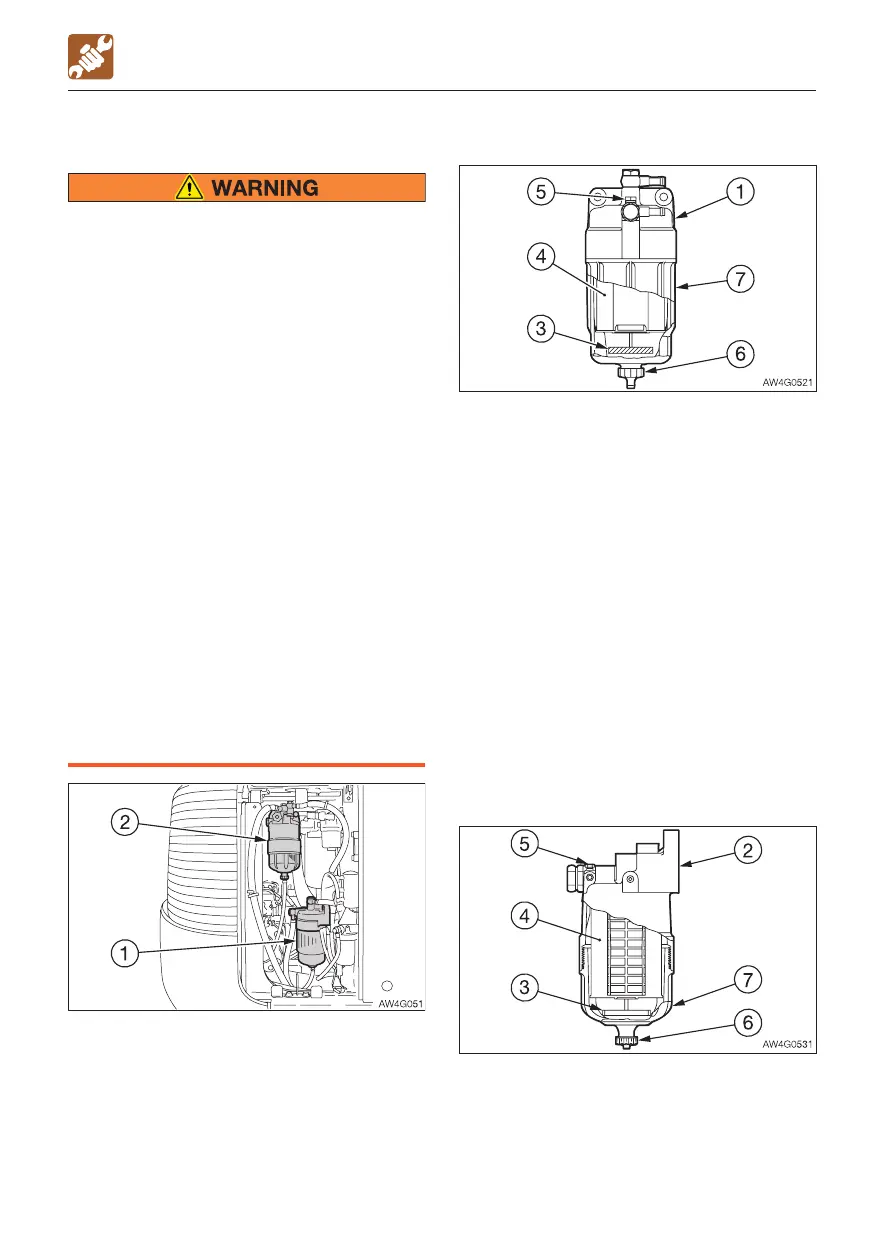

3. Loosen the vent plug (5) and the drain

plug (6) to drain the fuel inside.

4. Remove the case (7) by using a filter

wrench.

5. Replace the seals with new ones and

lubricate the new seals with diesel fuel.

6. Put the new element (length of 150 mm /

5.9 in) (4) in the case (7) and install by

hand until the seal makes contact with the

sealing surface.

7. Tighten the case (7) with the filter wrench.

· Tightening torque: 30 N·m (22.1 ft-lb)

8. Bleed air.

Refer to “Bleeding air from the fuel

system” on page 6-10.

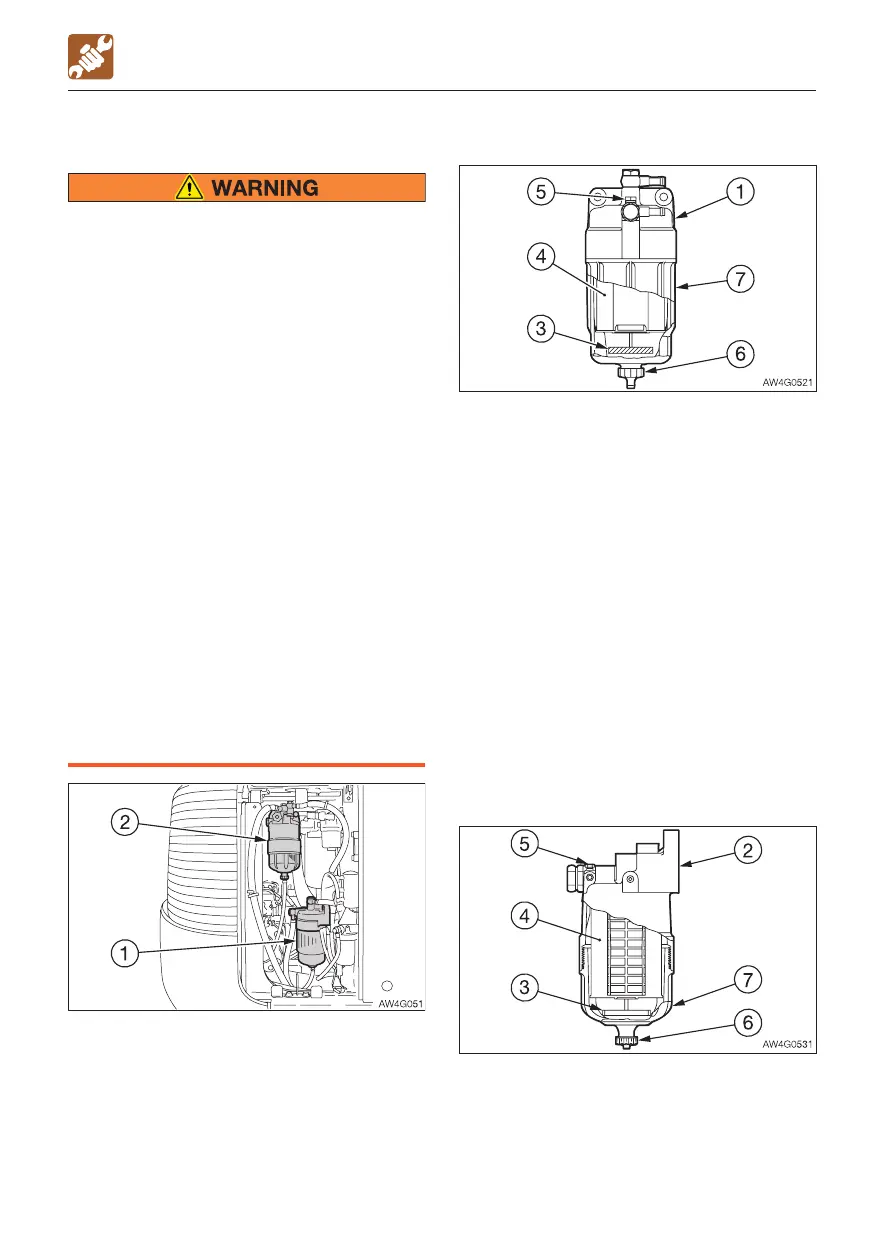

Main fuel filter

1. Open the right side cover.

REPLACING THE FUEL FILTERS

• Do not smoke or permit open flames

while handling fuel or working on the

fuel system.

• Stop the engine in a well-ventilated

place and allow it to cool down before

performing maintenance.

• Clean up spilled fuel immediately.

• Before performing maintenance on top

of the work bench, clean the footing and

observe the following precautions to

prevent falling.

· Do not spill oil or grease.

· Do not leave tools scattered around.

· Watch your step when walking.

• Never jump down from the machine or

the work bench. When getting on or off

the machine or work bench, use the

steps, handrails or work bench to

support your body. Your weight should

be evenly distributed among the three

contact points (one hand and two feet

or two hands and one foot).

• Do not stand on the dozer blade and

perform maintenance work. Doing so is

dangerous because of the unsteady

foothold. Use the work bench.

Pre-fuel filter

2. Place a pan under the main fuel filter (2) to

catch fuel.

3. Loosen the vent plug (5) and the drain

plug (6) to drain the fuel inside.

Loading...

Loading...