5-26

MAINTENANCE

INSPECTING AND ADJUSTING THE

COMPRESSOR BELT (AC)

Warning

•Stoptheengineandallowthemachine

to cool down before performing

maintenance.

· The engine, muffler, radiator, hydraulic

lines, sliding parts and many other

parts of the machine are hot

immediately after the engine is

stopped. Touching these parts will

cause burns.

•Thehigh-pressurepipesoftheair

conditioner can be very hot (80 to 120°C

or 176 to 248°F). Be careful not to burn

yourself.

IMPORTANT: Do not let any oil or grease

get on the belt. It will cause the belt to

slip, decrease the cooling capacity or

shorten the service life of the air

conditioner.

If the belt is too slack, it will slip and vibrate,

resulting in decreased cooling capacity. The

service life of the air conditioner also will be

shortened.Adjustthebelttensiontothe

standard value.

For TB285, 294 to 392 N or 66 to 88 lbf.

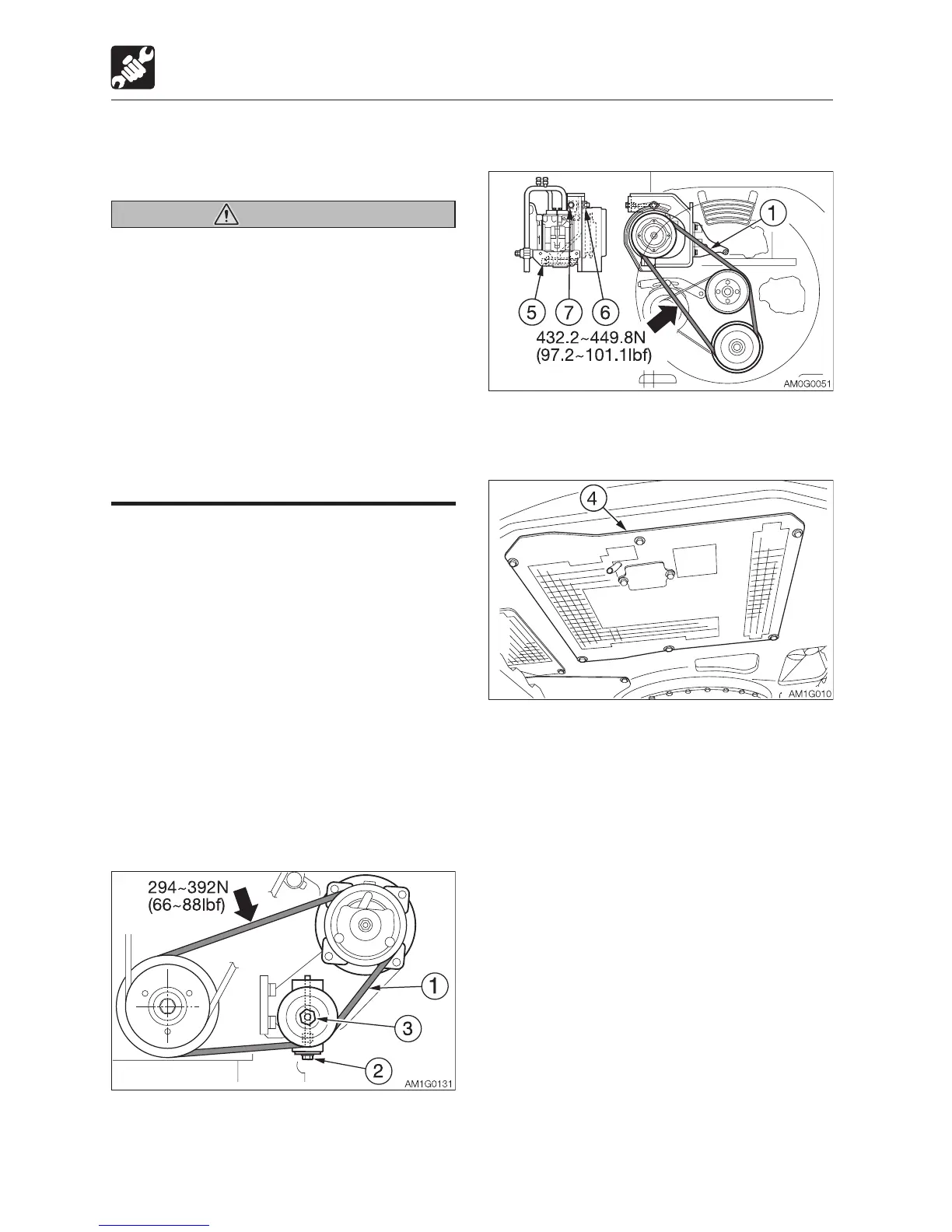

For TB290, 432.2 to 449.8 N or 97.2 to

101.1 lbf

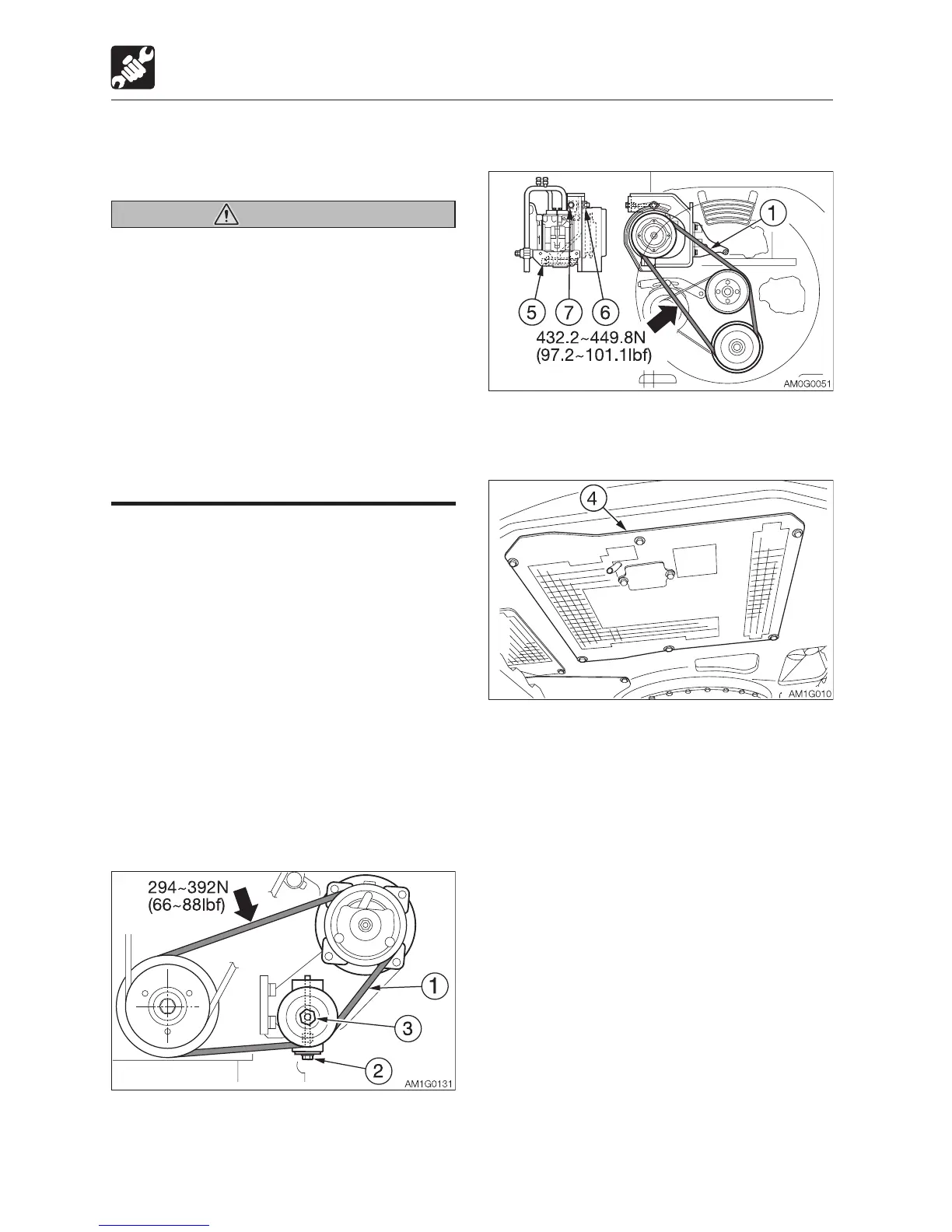

<TB285>

<TB290>

Inspection

<TB285>

1.Loosen

theboltsandremovetheunder

cover (4). <TB285>

1. Open the engine hood. <TB290>

2. Measure the belt (1) tension using the belt

tension gauge. The belt tension is normal

if the belt tension gauge indicates the

following values.

For TB285, 294 to 392 N or 66 to 88 lbf.

For TB290, 432.2 to 449.8 N or 97.2 to

101.1 lbf

AFTER THE INITIAL 50 HOURS (ONLY FOR NEW MACHINES)

Loading...

Loading...