5-48

MAINTENANCE

EVERY 1000 HOURS

REPLACING THE HYDRAULIC OIL

RETURN FILTER

Refer to “Replacing the hydraulic oil return

filter” on page 5-34.

EVERY 1000 HOURS

REPLACING THE PILOT LINE FILTER

Refer to “Replacing the pilot line filter” on

page 5-35.

REPLACING THE TRAVEL MOTOR GEAR

OIL

Refer to “Replacing the travel motor gear oil”

on page 5-36.

CLEANING THE ENGINE COOLING

SYSTEM

Warning

•Stoptheengineandallowthemachine

to cool down before performing

maintenance.

· The engine, muffler, radiator and many

other parts of the machine are hot

immediately after the engine is

stopped. Touching these parts will

cause burns.

· The engine coolant is also hot and

under high pressure immediately after

the engine is stopped. Be careful

when loosening the caps or plugs.

Working on the machine under these

conditions could result in burns or

injuries due to the hot coolant spurting

out.

•Ifmaintenancemustbeperformedwith

the engine running, always work as a

two person team communicating each

other.

· One person must sit in the operator’s

seat so that he/she can immediately

stop the engine when necessary. He/

she must take care not to touch the

lever or pedal unless necessary.

· The one who performs maintenance

must make sure to keep his/her body

or clothing away from the moving part

of the machine.

•Standingatthebackofthemachine

while the engine is running is extremely

dangerous, as the machine could move

suddenly. Never stand at the back of the

machine while the engine is running.

•Donotremovetheradiatorcaporthe

drain plug when the cooling water is

hot. Stop the engine and wait until the

engine and the cooling water cool.

Then, slowly loosen the radiator cap

and the drain plug to remove them.

When cleaning, if the temperature of the

coolant is low, the thermostat will be closed

and the coolant will not circulate in the

radiator.Heatthecoolantwatertoatleast

90°C (194°F) before cleaning.

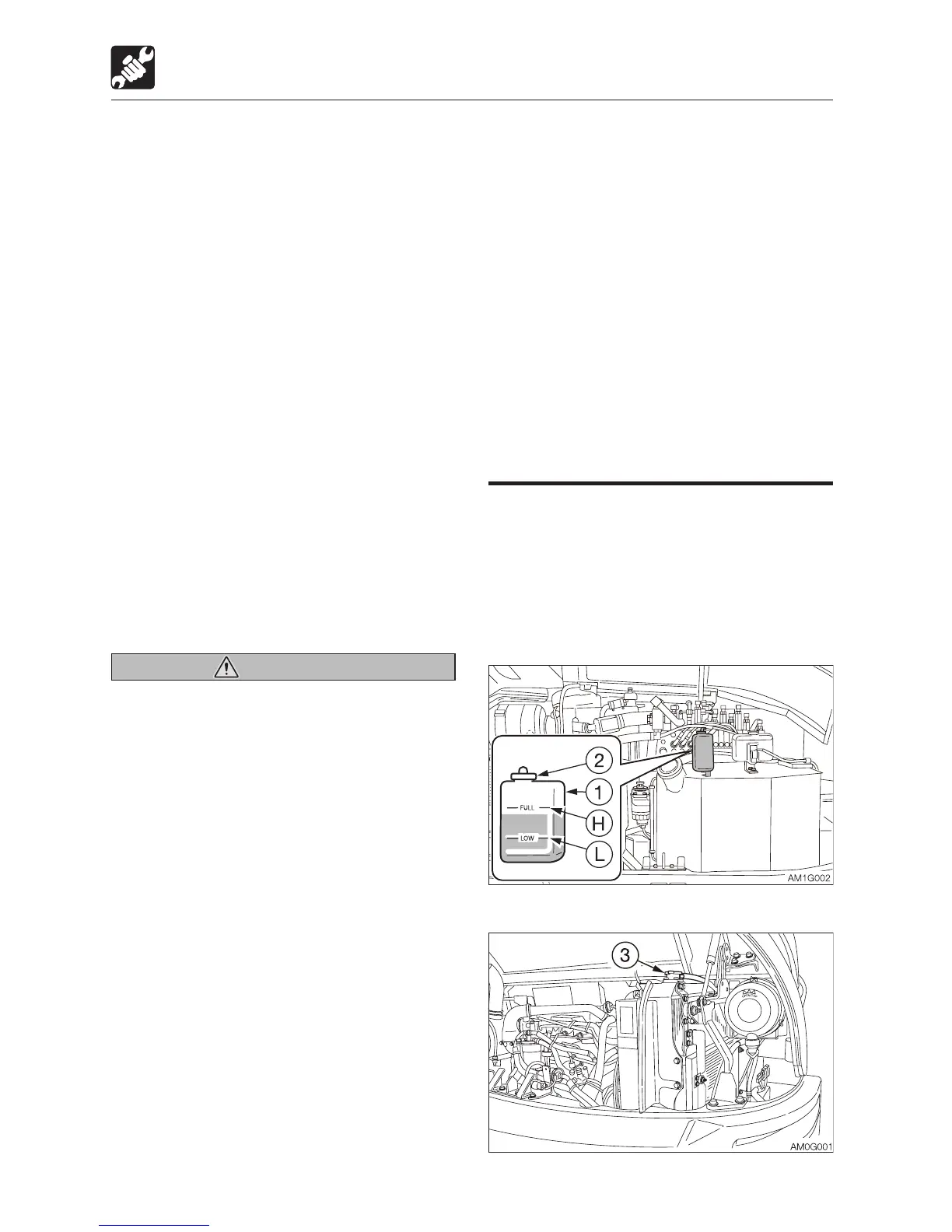

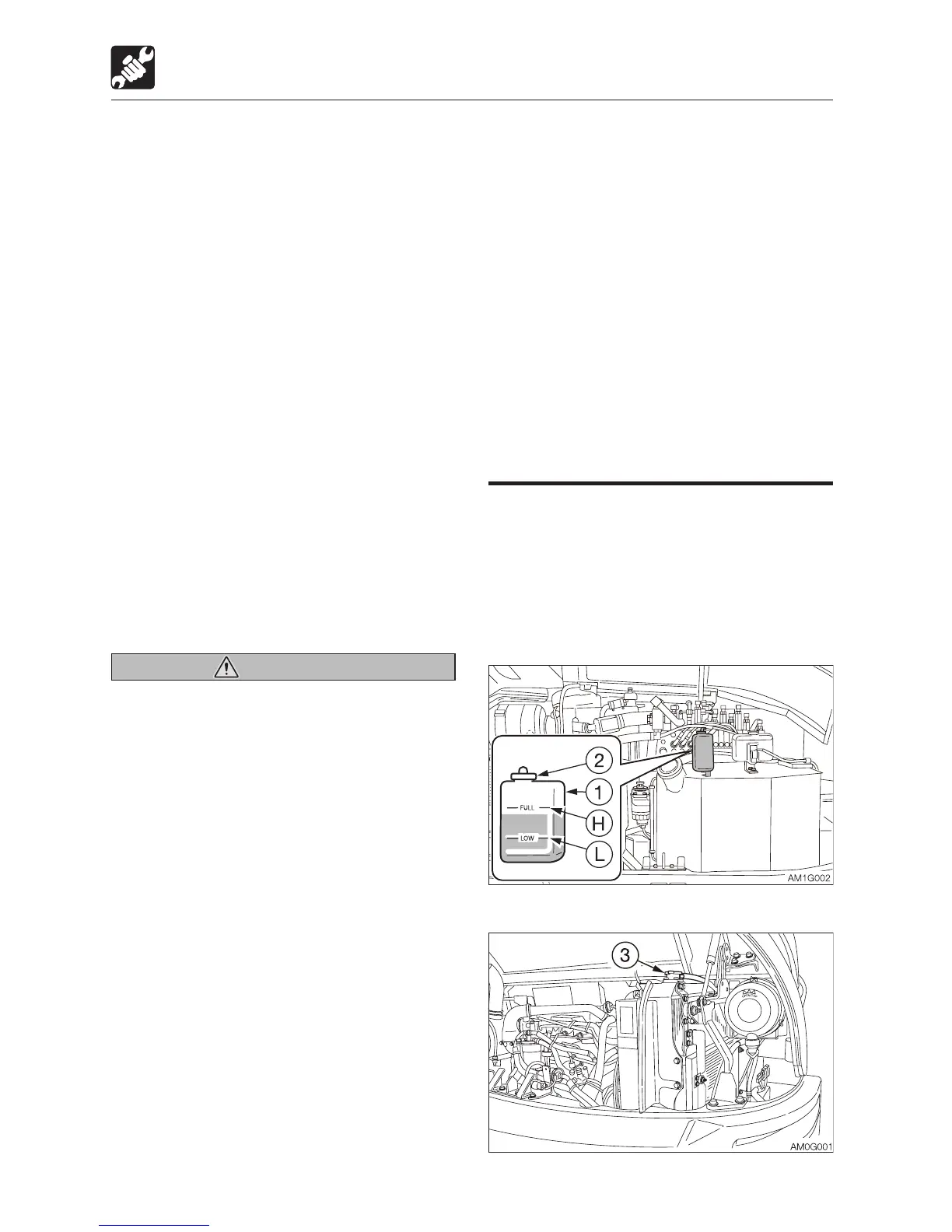

1. Open the engine hood and the side cover.

<TB285>

<TB290>

Loading...

Loading...