Multi Pro 1750

Page 5 − 5

Electrical System

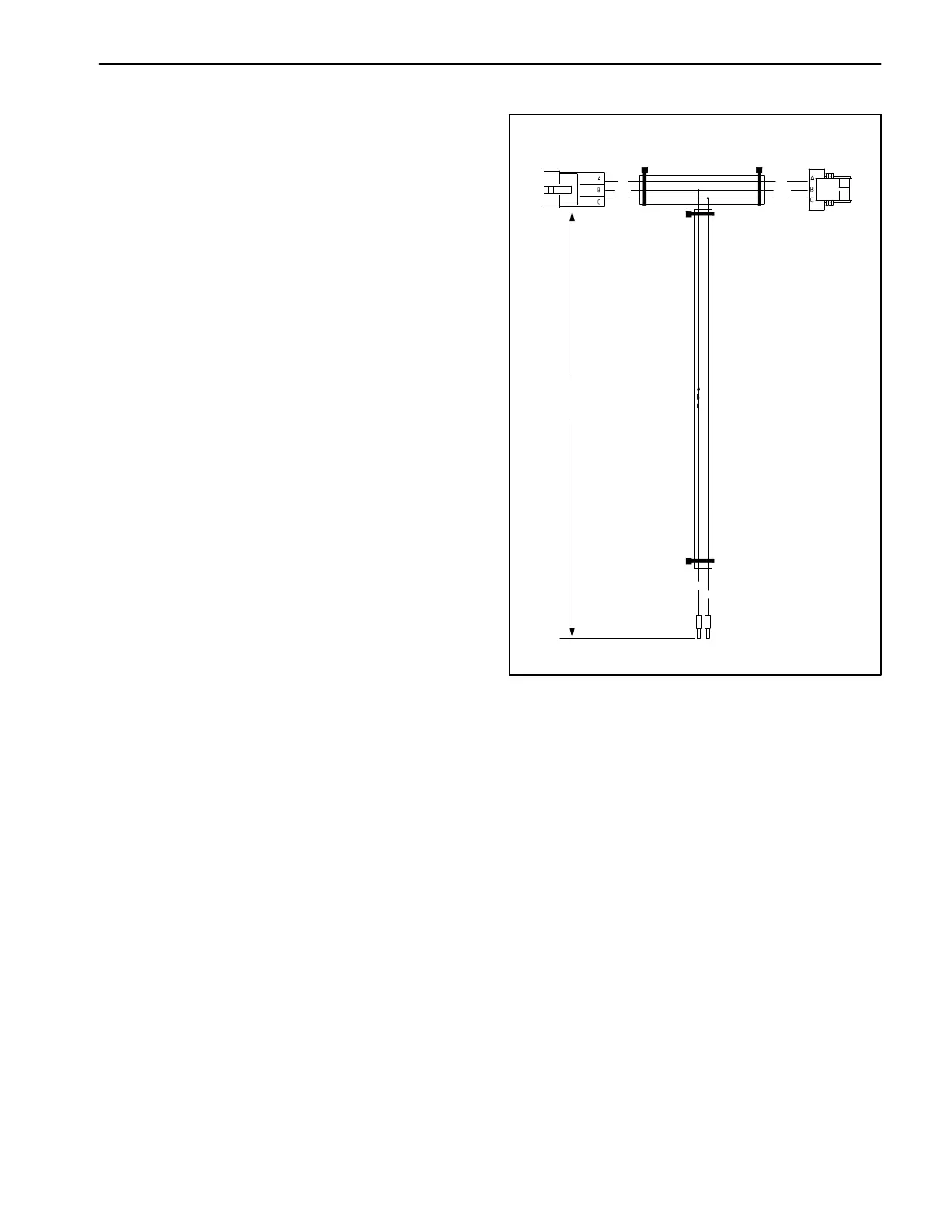

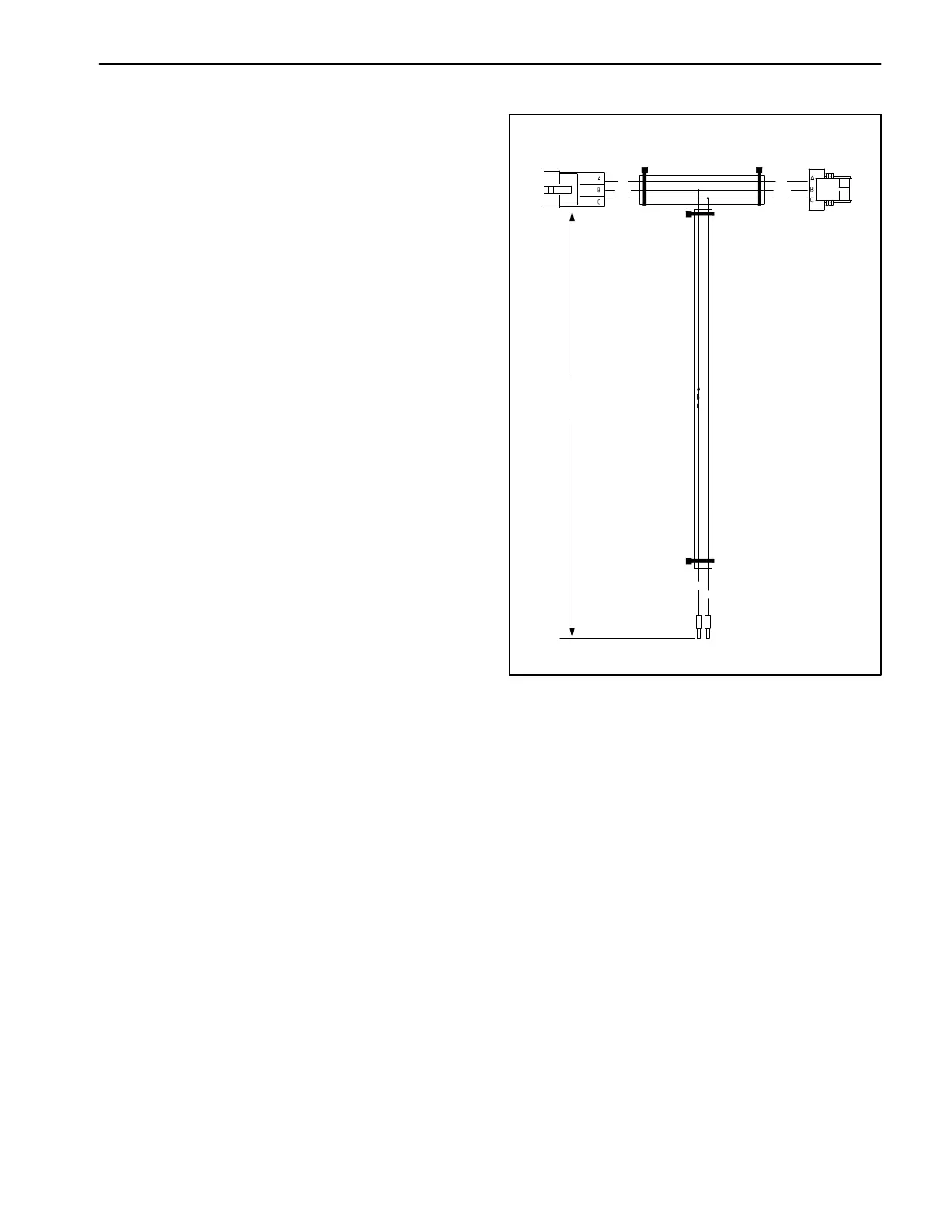

Traction Speed Sensor Test Harness

NOTE: Based on harness length, speed sensor testing

can be performed while driving machine in an open area

or while the machine is stationary. Stationary testing re-

quires an assistant and using jack stands to get the rear

wheels off the ground.

Special Tools Needed

Traction speed sensor test harness (fabricated using

the information provided here)

Multimeter with frequency measurement capability

(12V square wave)

Instructions

1. Park machine on a level surface, stop engine and en-

gage parking brake. Remove key from ignition switch.

2. Disconnect sensor from wire harness and check wire

harness for circuit problems before testing speed sen-

sor (see Traction Speed Sensor in the Component Test-

ing section of this chapter).

3. With sensor installed in transaxle, connect traction

speed sensor test harness between sensor and ma-

chine harness.

4. Plug blue wire (red test harness connector) into the

positive voltage port on the multimeter and black wire

(black test harness connector) into ground port on the

multimeter.

5. Set multimeter to measure frequency (12V square

wave).

6. Start and drive machine while watching the meter.

The frequency should increase when vehicle speed in-

creases if the sensor is functioning appropriately.

7. If frequency is not registered, is erratic, or does not

increase when increasing speed, remove and replace

the speed sensor. See Traction Speed Sensor in the

Service and Repairs section of this chapter.

Figure 6

Traction Speed Sensor Test Harness

TO SPEED SENSOR

PAKARD 12110293

FEMALE CONNECTOR

NEGATIVE (−)

CONNEECTORS COMPATIBLE WITH

MULTIMETER USED

POSITIVE (+)

14 ft (4.27 m)

TO SAFELY REACH

OPERATOR SEAT

TO MACHINE HARNESS

PAKARD 12129615

MALE CONNECTOR

BU

BK

BU

BK

R

BU

BK

R

Loading...

Loading...