Multi Pro 1750

Page 5 − 20

Electrical System

Troubleshooting

CAUTION

Remove all jewelry, especially rings and

watches, before doing any electrical trouble-

shooting or testing. Also, disconnect the battery

cables unless the test requires battery voltage.

For effective troubleshooting and repairs, you must

have a good understanding of the electrical circuits and

components used on this machine (see electrical

schematics and wire harness drawings in Chapter 10 −

Electrical Drawings).

If the machine has any interlock switches by−passed,

reconnect the switches for safety and efficient trouble-

shooting.

NOTE: .Check the InfoCenter Display for possible op-

erator advisories or faults whenever diagnosing ma-

chine electrical problems.

Operator Advisory Screen

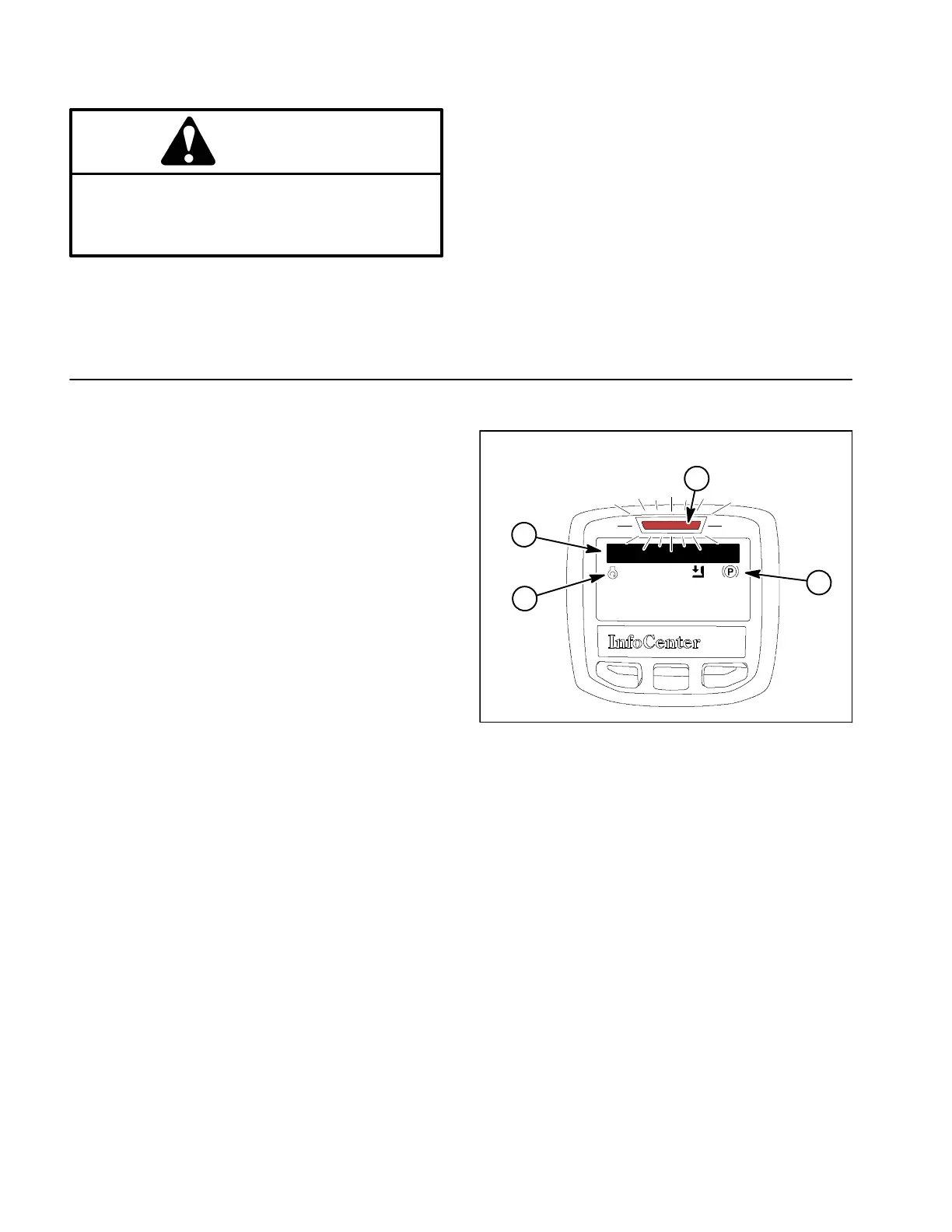

If one or more Toro Electronic Controller (TEC) inputs

are not in the correct position to allow certain machine

operations, or are malfunctioning, the fault indicator will

illuminate and an advisory screen will appear on the

InfoCenter Display (Fig. 22). Each advisory screen has

three elements: the advisory number/code, the advisory

description, and the advisory qualifier.

An advisory qualifier denotes the condition(s) that

triggered the advisory and provides instruction on elimi-

nating the advisory. An operator advisory may involve

one or more advisory qualifier. Typically, an advisory can

be eliminated by changing the position of the operator

control(s) referenced by the advisory qualifier. Once the

first qualifier displayed is satisfied, any additional quali-

fiers that remain to be satisfied will appear in the opera-

tor advisory screen individually.

NOTE: If a machine fault occurs during machine opera-

tion, the InfoCenter fault indicator will blink to notify the

operator (see Faults Screen in this chapter).

ADVISORY #202

Prevented:

or

1. Fault indicator

2. Advisory number/code

3. Advisory description

4. Advisory qualifier

Figure 22

OPERATOR ADVISORY SCREEN

2

3

4

1

Loading...

Loading...