Multi Pro 1750Page 7 − 36Drive Train

Transaxle Assembly

1. Clean gasket material from all transaxle mating sur-

faces before assembling transaxle. Make sure all parts

are clean and free of dirt and dust.

IMPORTANT: Be careful to not damage mating sur-

faces when removing gasket material.

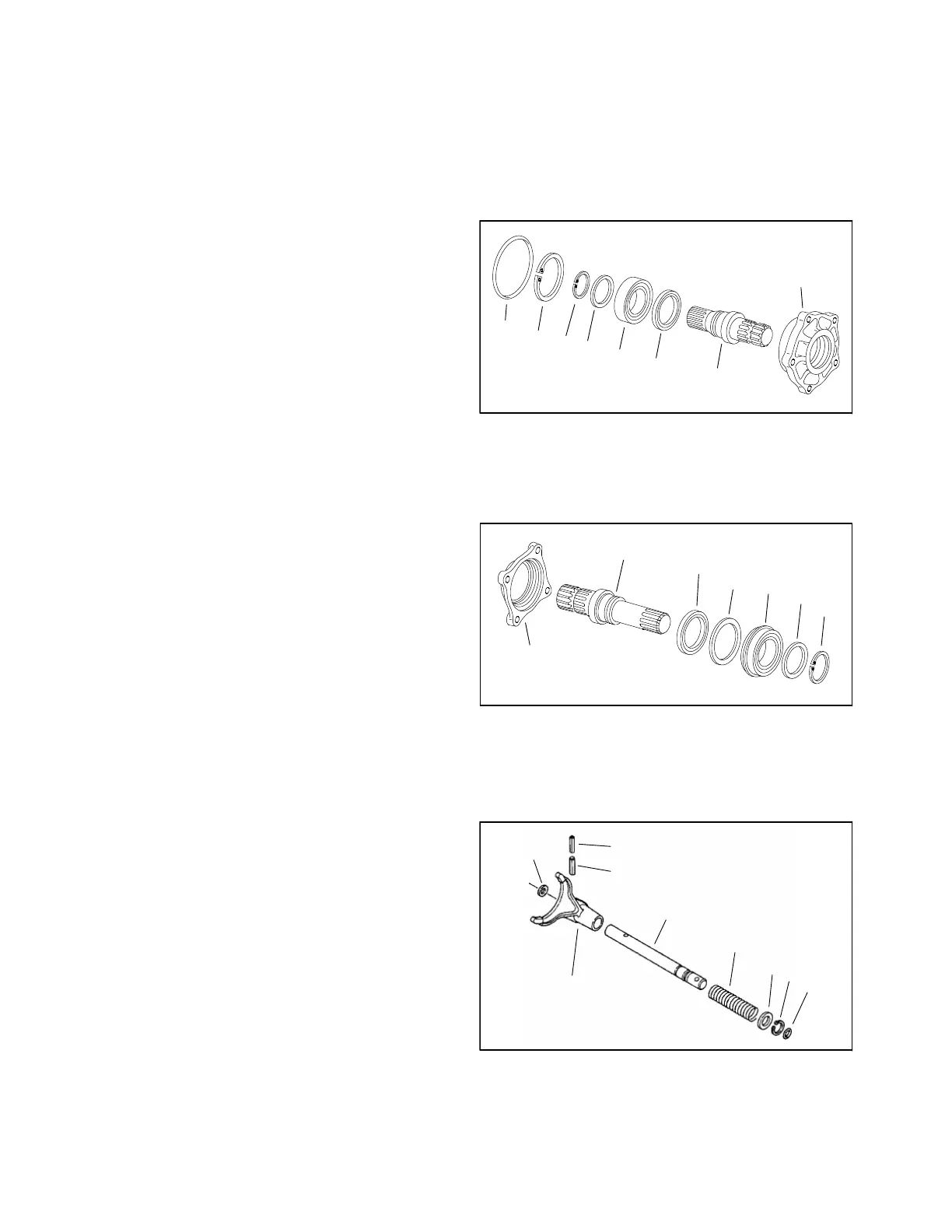

2. Assemble L.H. axle shaft:

A. Install new oil seal into differential carrier.

B. Use a press to install bearing onto L.H. axle shaft.

C. Install washer and snap ring.

D. Install L.H. axle shaft assembly into differential

carrier.

E. Install snap ring.

F. Install new O−ring. Apply multi−purpose grease

on O−ring before installing.

L.H. AXLE SHAFT

2

3

6

8

1

5

7

4

1. O−ring

2. Snap ring

3. L.H. axle shaft assembly

4. Snap ring

5. Washer

6. Bearing

7. Oil seal

8. Differential carrier

Figure 55

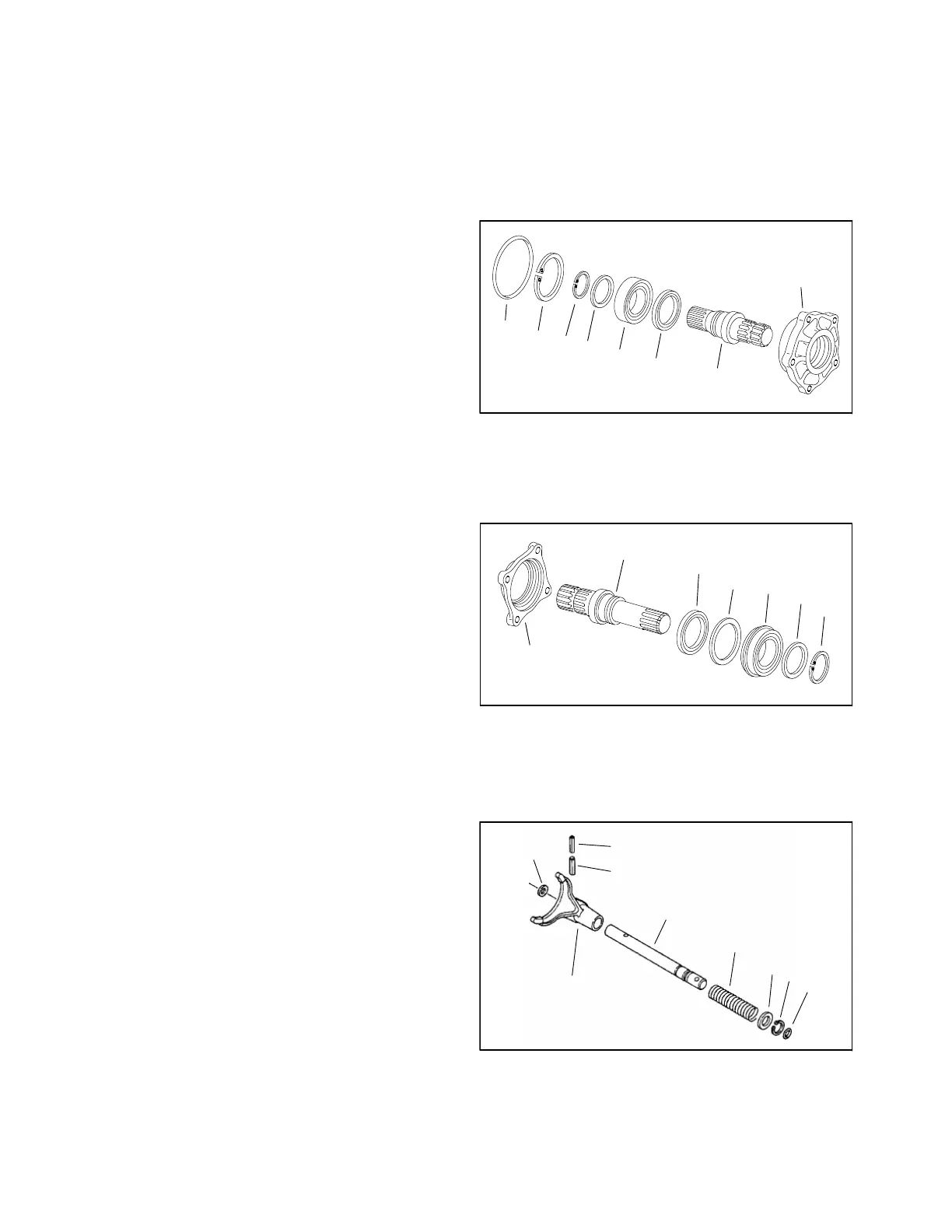

3. Assemble R.H. axle shaft:

A. Install new oil seal into seal cover. Apply multi−

purpose grease on O−ring before installing.

B. Insert washer.

C. Use a press to install bearing onto R.H. axle shaft.

D. Install washer and snap ring.

E. Install R.H. axle shaft assembly into seal cover.

R.H. AXLE SHAFT

2

3

6

1

5

4

7

Figure 56

1. R.H. axle shaft assembly

2. Snap ring

3. Washer

4. Bearing

5. Oil seal

6. Washer

7. Seal cover

4. Assemble differential lock fork shaft:

A. Drive lock pins into fork shaft. Make sure lock pins

are installed with slit facing the correct direction.

B. Install fork, spring, washer and snap ring onto

fork shaft using a press. Apply moly disulfide grease

onto fork portion of fork shaft before installing.

C. Install new O−ring. Apply multi−purpose grease

on O−ring before installing.

1. O−ring

2. Snap ring

3. Washer

4. Spring

5. Fork

6. Roll pin

7. Roll pin

8. Washer

9. Fork shaft

Figure 57

6

5

4

3

2

1

7

8

9

Loading...

Loading...