Multi Pro 1750

Page 5 − 35

Electrical System

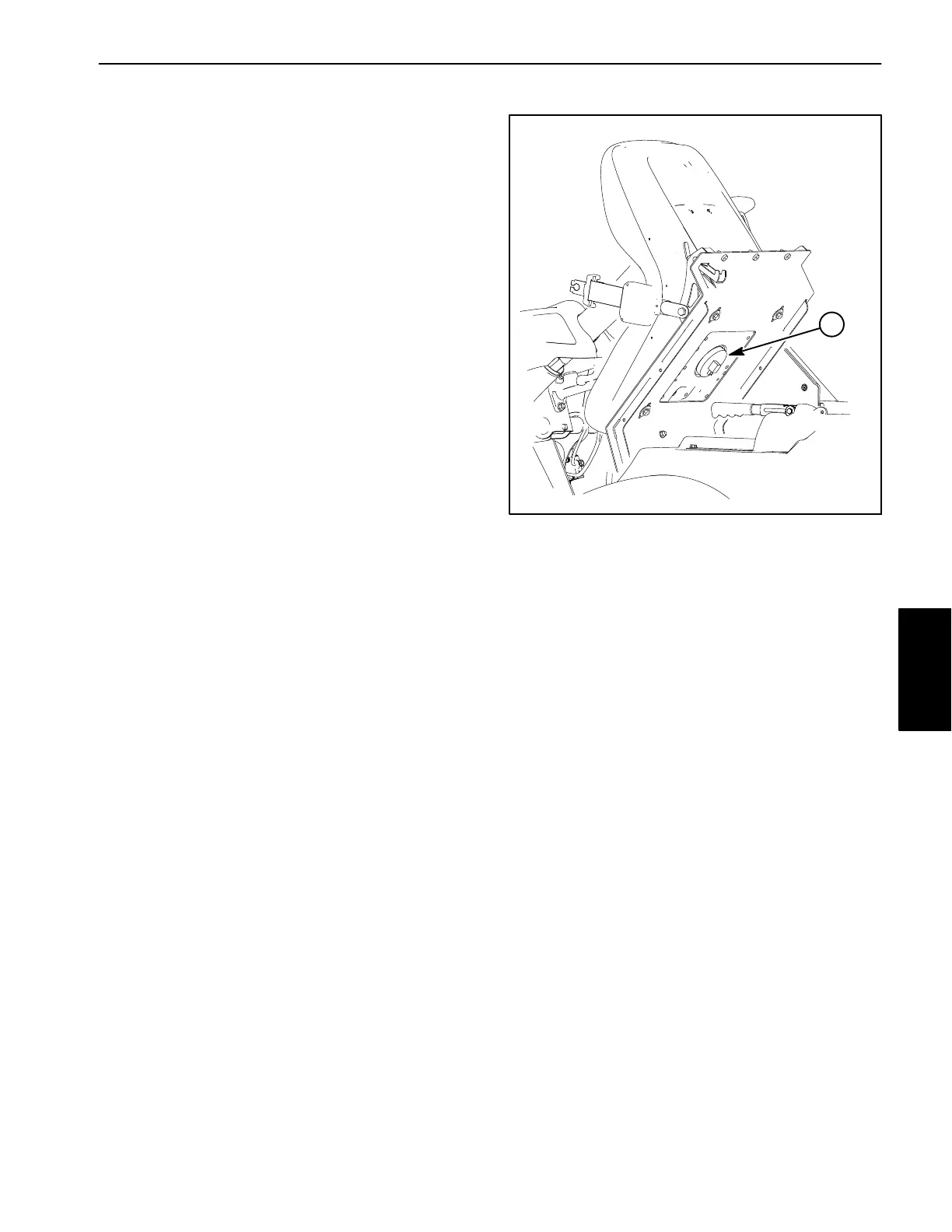

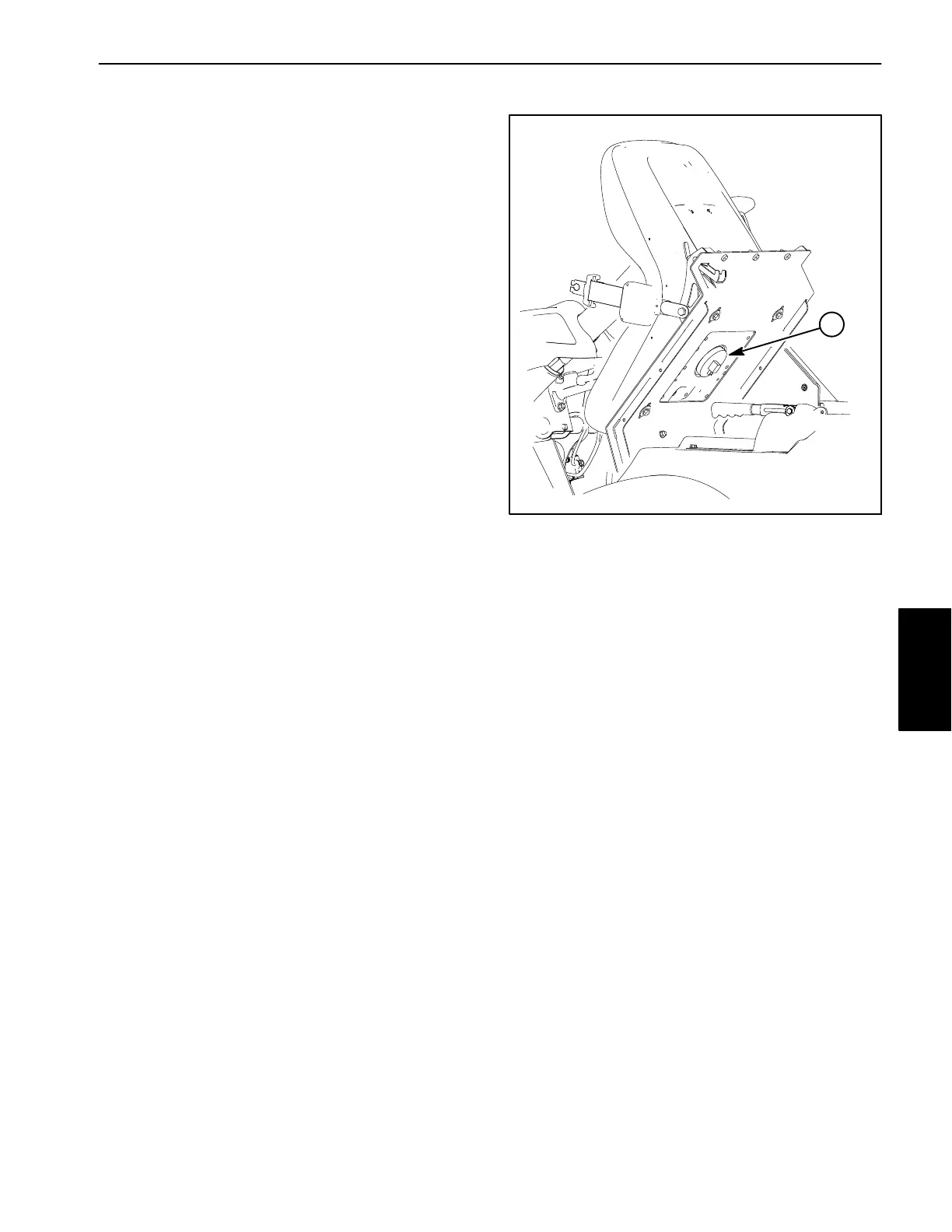

Operator Seat Switch

The seat switch is normally open and closes when the

operator seat is occupied. If the parking brake is not en-

gaged when the operator raises out of the seat, the en-

gine will stop. The seat switch is located directly under

the operator seat. The Toro Electronic Controller (TEC)

monitors the operation of the seat switch (input).

Testing

The seat switch and its circuit wiring can be tested as a

TEC qualifier using the InfoCenter Display (see In-

foCenter Display − Diagnostics Screen in this chapter).

If testing determines that the switch and circuit wiring are

not functioning correctly, proceed with the following test

procedure:

1. Park machine on a level surface, stop spray pump,

stop engine and engage parking brake. Remove key

from ignition switch.

2. Raise and support operator seat to access seat

switch.

3. Disconnect wire harness electrical connector from

the seat switch under the operator seat (Fig. 35).

4. Check the continuity of the switch by connecting a

multimeter (ohms setting) across the switch connector

terminals.

5. With no pressure on the seat, there should be no

continuity (infinite ohms resistance) between the seat

switch terminals.

6. Press directly onto the seat switch through the seat

cushion. There should be continuity (zero ohms resis-

tance) between the seat switch terminals as the seat

cushion approaches the bottom of its travel.

7. If testing determines that seat switch is faulty, re-

place switch.

8. If the seat switch tests correctly and a circuit problem

still exists, check wire harness (see Electrical Schemat-

ic and Wire Harness Drawings in Chapter 10 − Electrical

Drawings in this manual).

9. After seat switch testing is completed, connect wire

harness electrical connector to the seat switch. Lower

and secure seat.

1. Seat switch

Figure 35

1

Electrical

System

Loading...

Loading...