Section 3 - Service & Repair Hydraulics

505115-000 Pa

e 3-9

3-7 H

YDRAULICS

H

YDRAULIC

O

IL

T

ANK

A

ND

F

ILTER

F

LUID

L

EVEL

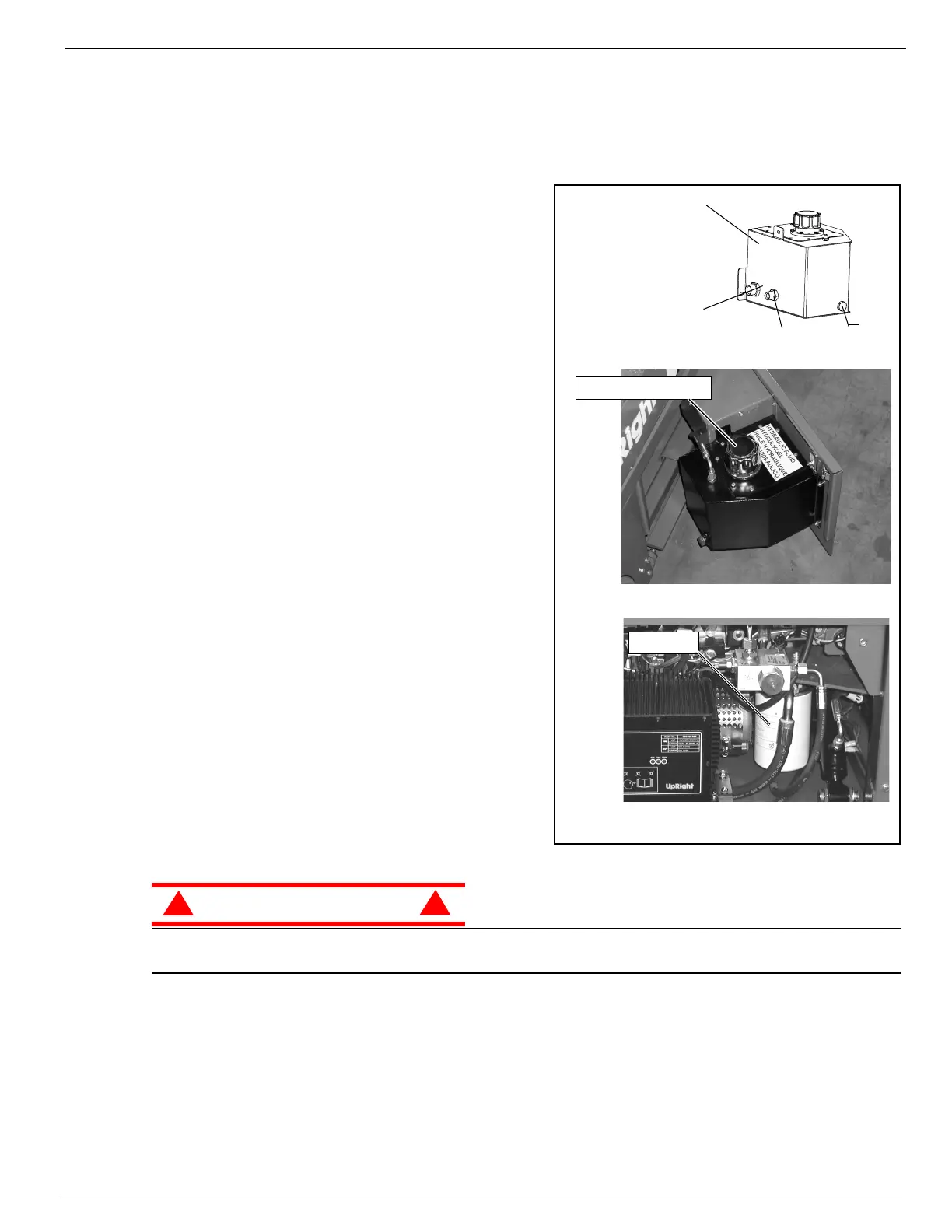

Figure 3-5: Hydraulic Oil Tank and Filter

With Platform fully lowered, oil should be visible on the

dipstick, if not, fill the tank until oil registers on the dip-

stick. DO NOT fill above the lower line on the dipstick

or when the Platform is elevated.

O

IL

AND

F

ILTER

R

EPLACEMENT

1. Operate the work platform for 10-15 minutes to

bring the hydraulic oil up to normal operating tem-

perature.

2. Provide a suitable container to catch the drained oil.

Hydraulic tank has a 7,2 liter (1.9 US gal.) capacity.

3. Open module door.

4. Remove the magnetic drain plug and allow all oil to

drain.

5. Check the magnetic plug for metal fragments.

6. Clean and re-install the drain plug.

7. Un-thread the suction screen from the tank.

8. Wash the suction screen in cleaning solvent and

then blow out with clean compressed air.

9. Apply a thin film of clean hydraulic oil (ISO #46) to

the threads and re-install the suction screen.

10. Un-thread the filter from the filter head.

11. Apply a thin film of clean hydraulic oil (ISO #46) to

the gasket of the replacement filter.

12. Thread the replacement filter onto the filter head

until the gasket makes contact, then rotate the filter

¾ of a turn further.

13. Fill the hydraulic reservoir with hydraulic oil until the

oil comes up just past the end of the dipstick.

Hydraulic tank has a 7,2 liter (1.9 US gallon)

capacity.

CAUTION

!

!

The hydraulic oil may be of sufficient temperature to cause burns. Wear safety gloves and safety

glasses when handling hot oil.

Right Side Door

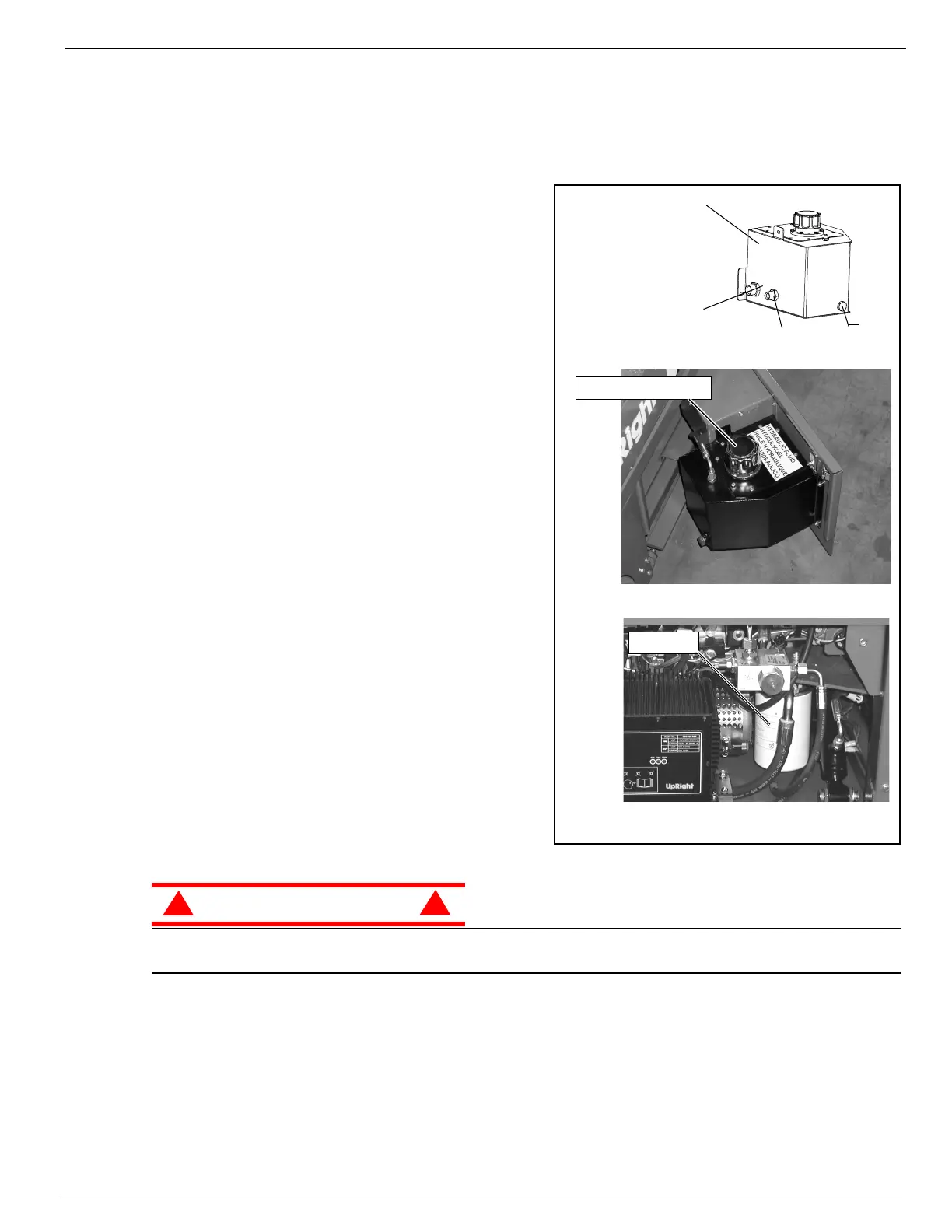

Left Side, Behind Panel

Filter

Filler Cap

1. Tank

2. Drain Plug

3. Hose Fitting

4. Suction Screen

2

4

3

Filter

Loading...

Loading...