Installation, Operating & Maintenance Instructions

Series 650 DN 100-250 (I.D. 4“ - 10”), CC-Link

VAT Vakuumventile AG, CH-9469 Haag, Switzerland

Tel +41 81 771 61 61 Fax +41 81 771 48 30 CH@vatvalve.com www.vatvalve.com

280672EB

2010-12-15

37/94

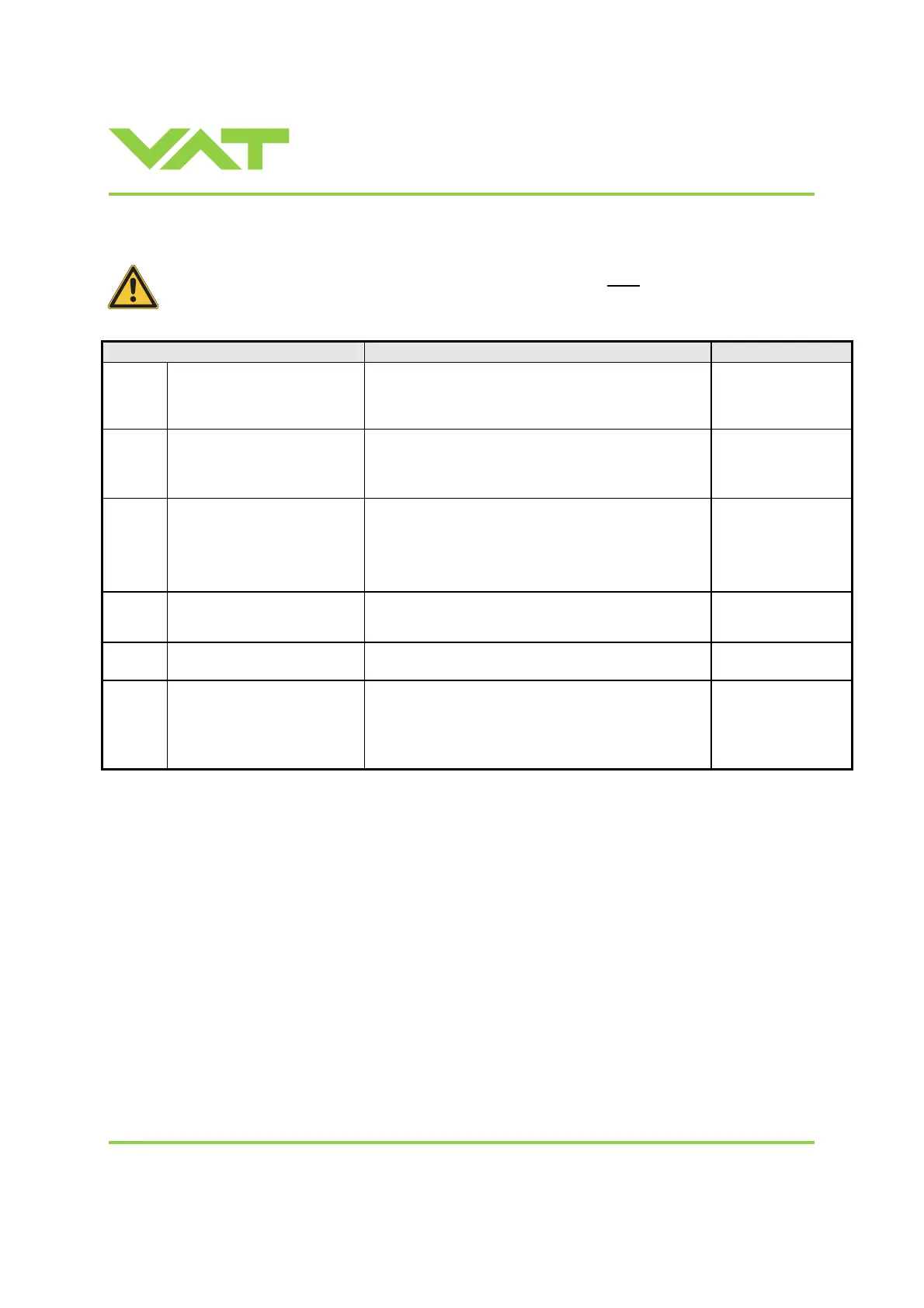

3.6 Setup procedure

To enable the valve cluster for pressure control setup steps 1 to 6 must

be performed.

In case position control is required only it’s sufficient to perform steps 1 to 4.

Setup step Description Valve

1

Power up

Turn on external + 24VDC power supply for all valves

(and external ±15 VDC for sensor power supply on

master valve if required). Refer to chapter «Behavior

during power up» for details.

Master & Slave

2

Cluster address

configuration

Set the cluster address for each individual valve

(Master and Slave(s)). This must be done via the

service port on each valve. Refer to chapter «Cluster

address configuration» for details

Master & Slave

3

CC-Link configuration

1. Station Number

2. Transmission rate

3. Operational settings mode

Refer to chapter «CC-Link configuration» for

details.

Master

4

Valve and sensor

configuration

Basic configurations of the Master valve must be

adapted according to application needs. Refer to

chapter «Valve and sensor configuration» for details.

Master & Slave

5

ZERO

Compensation of the sensor offset voltage.

Refer to chapter «ZERO» for details.

Master

6

LEARN

Determination of the vacuum system characteristic to

accommodate the PID controller. Refer to chapter

«LEARN» for details.

Note: Without LEARN the valve is not able to run

pressure control

Master

3.6.1 Cluster address configuration

When setting up the valve cluster solution, each valve needs a unique cluster address.

This address must be configured on each valve prior to operation via the service port by using the graphical interface

(SETUP –> CLUSTER) or the Terminal function of the Control View software or Control Performance Analyzer software.

The used addresses must be in a consecutive order.

Further the Master valve needs the information about the total number of valves (including itself) connected to the valve

cluster.

Note: Prior to sending the address command, set the valve to LOCAL operation.

Loading...

Loading...