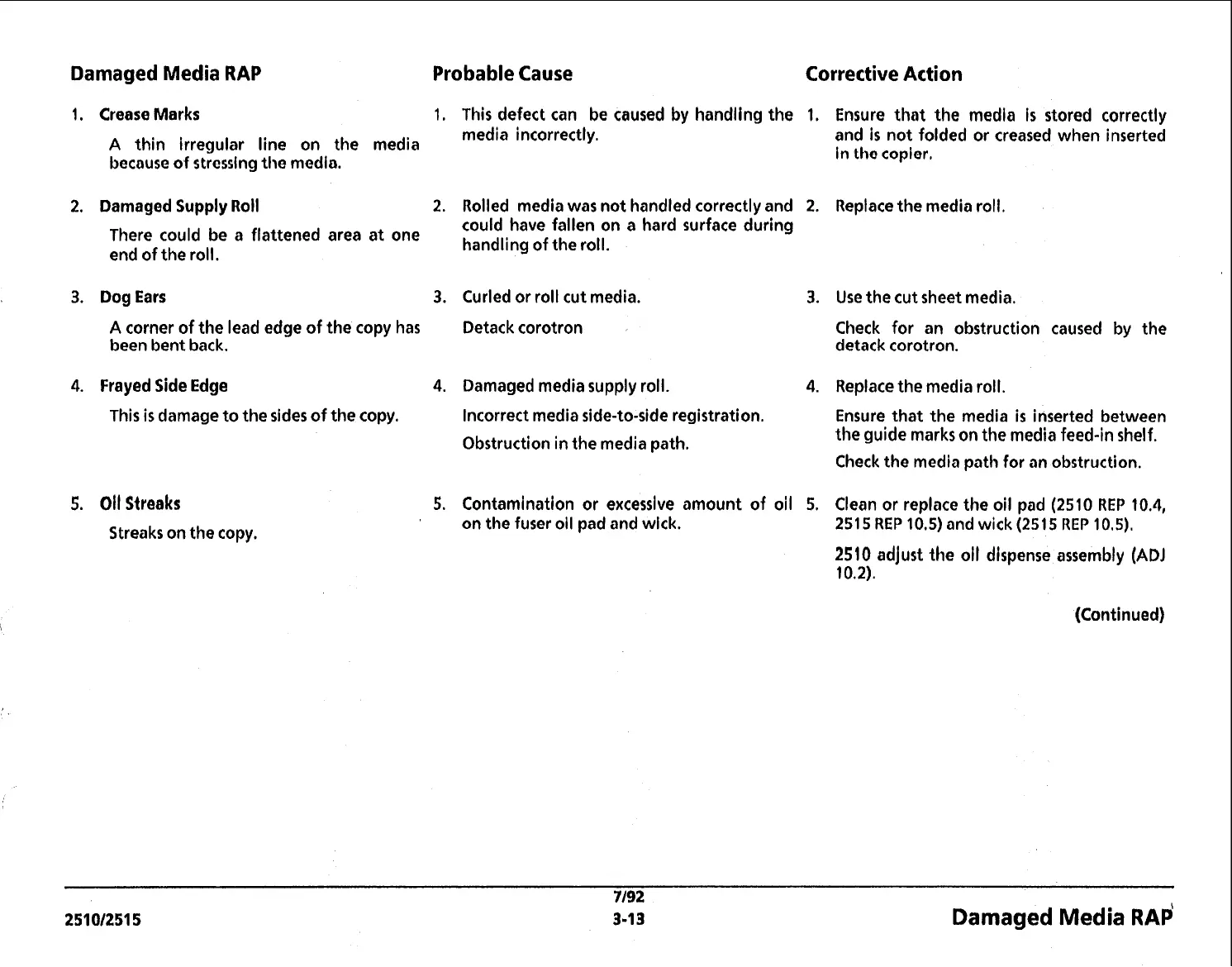

Damaged Media RAP Probable Cause Corrective Action

1.

Crease Marks

1.

A

thin irregular line on the media

because of stressing the media.

2.

Damaged Supply Roll

2.

There could be a flattened area at one

end of the roll.

3.

Dog Ears

3.

A

corner of the lead edge of the copy has

been bent back.

4.

Frayed Side Edge

4.

This

is

damage to the sides of the copy.

5.

Oil

Streaks

5.

Streaks on the copy.

This defect can be caused by handling the

1.

media incorrectly.

Rolled media was not handled correctly and

2.

could have fallen on

a

hard surface during

handling of the roll.

Curled or roll cut media.

Detack corotron

Damaged media supply roll.

4.

Incorrect media side-to-side registration.

Obstruction in the media path.

Contamination or excessive amount of oil

5.

on the fuser oil pad and wick.

Ensure that the media

is

stored correctly

and

is

not folded or creased when inserted

in

tho

copier,

Replace the media roll.

Use the cut sheet media.

Check for an obstruction caused

by

the

detack corotron.

Replace the media roll.

Ensure that the media

is

inserted between

the guide marks on the media feed-in shelf.

Check the media path for an obstruction.

Clean or replace the oil pad

(2510

REP

10.4,

2515

REP

10.5) and wick (2515

REP

10.5).

2510

adjust the oil dispense assembly

(ADJ

10.2).

(Continued)

Damaged Media

RAP'

Loading...

Loading...