Photoreceptor Drum Maintenance

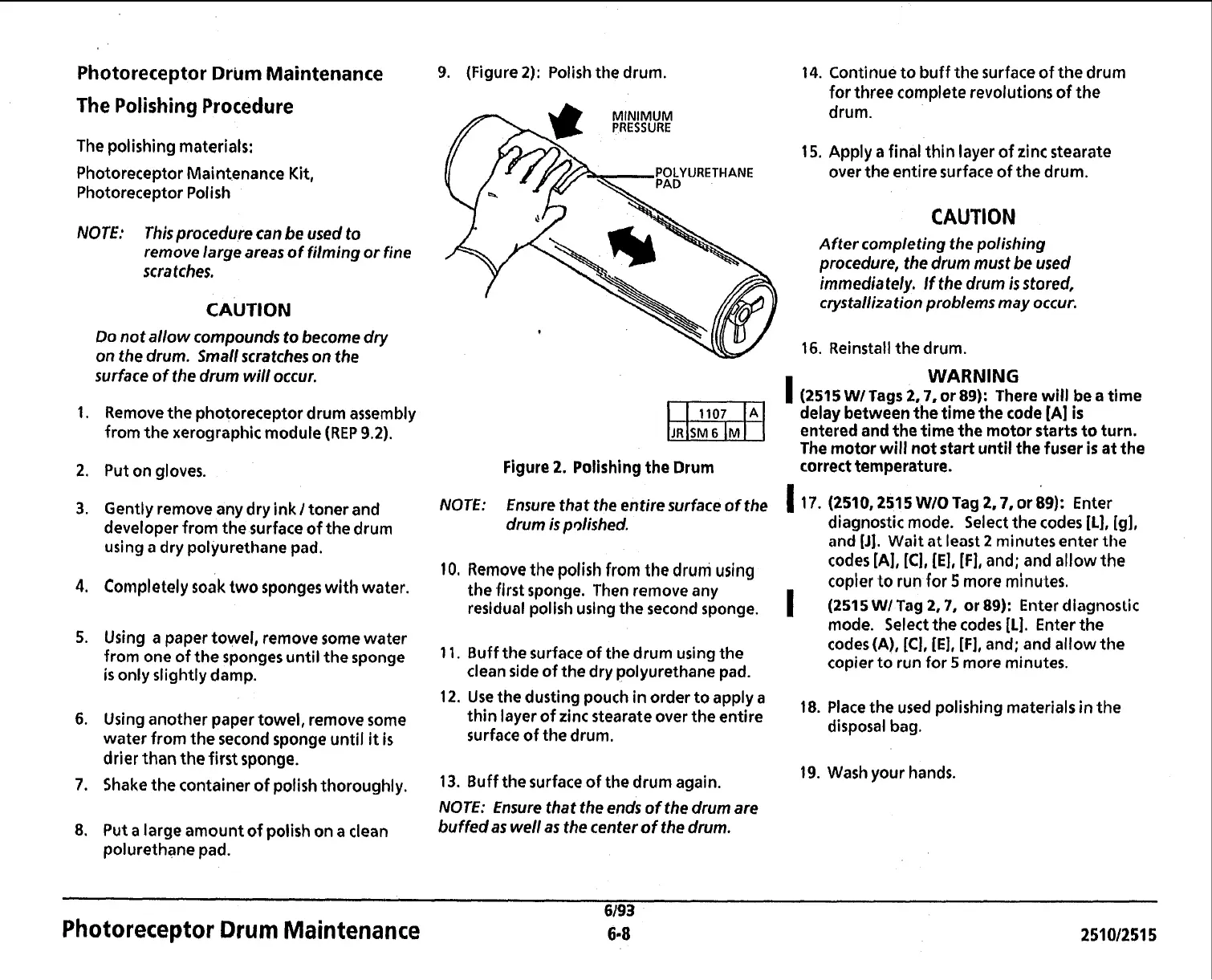

9.

(Figure

2):

Polish the drum.

The Polishing

Procedure

The polishing materials:

Photoreceptor Maintenance

Kit,

Photoreceptor Polish

NOTE:

This procedure

can

be used to

remove large areas of filming or fine

scratches.

CAUTION

Do not allow compounds to become dry

on the drum. Small scratches on the

surface of the drum will occur.

1.

Remove the photoreceptor drum assembly

from the xerographic module (REP

9.2).

2.

Put on gloves.

3.

Gently remove any dry ink/ toner and

developer from the surface of the drum

using

a

dry polyurethane pad.

4.

Conipletely soak two sponges with water.

5.

Using a paper towel, remove some water

from one of the sponges until the sponge

is

only slightly damp.

6.

Using another paper towel, remove some

water from the second sponge until

it

is

drier than the first sponge.

7.

Shake the container of polish thoroughly.

8.

Put a large amount of polish on a clean

polurethane pad.

POLYURETHANE

14.

Continue to buff the surface of the drum

for three complete revolutions of the

drum.

15.

Apply a final thin layer of zinc stearate

over the entire surface of the drum.

CAUTION

After completing the polishing

procedure, the drum must be used

immediately.

If

the drum is stored,

crystallization problems may occur.

16.

Reinstall the drum.

WARNING

,

I

(2515

WI Tags

2,7,

or 89): There

will

be

a time

delay between the time the code [A] is

JR

SM~

M

entered and the time the motor starts to turn.

The motor will not start until the fuser is at the

Figure

2.

Polishing the Drum

correct temperature.

NOTE:

Ensure that the entire surface of the

1

17.

(2510.2515W10

Tag

2.7,

or& Enter

drum is pelished.

diagnostic mode. Select the codes [L],

[g],

and

[J].

Wait at

least

2

minutes enter the

10.

Remove the polish from the drum using

codes [A], [C], [El, [F], and; and allow the

the first sponge. Then remove any

copier to run for

5

more minutes.

residual polish uslng the second sponge.

1

(2515W/TKl2.71 or89): Enterdiagnoslic

mode. Select the codes [Ll. Enter the

1

1.

Buff the surface of the drum using the

clean side of the dry polyurethane pad.

codes

(A),

[Cl,

[El,

[F], and; and allow the

copier to run for

5

more minutes.

12'

Use

the

dusting pouch

in

order

to

a

18.

Place

the polishing

materials

in

the

thin layer of zinc stearate over the entire

surface of the drum.

disposal bag.

13.

Buff the surface of the drum again.

19.

Wash your hands.

NOTE:

Ensure that the ends of the drum are

buffed as well as the center

of

the drum.

Photoreceptor

Drum

Maintenance

Loading...

Loading...