Jam and Misfeed Troubleshooting

Phaser® 6120 Color Laser Printer Service Manual

9-16

Jam and Misfeed Troubleshooting Procedures

Initial Actions

When a paper misfeed occurs, first check the following initial check items.

Misfeed at Duplex Unit Reverse Drive/Storage Section

Detection Timing

Actions

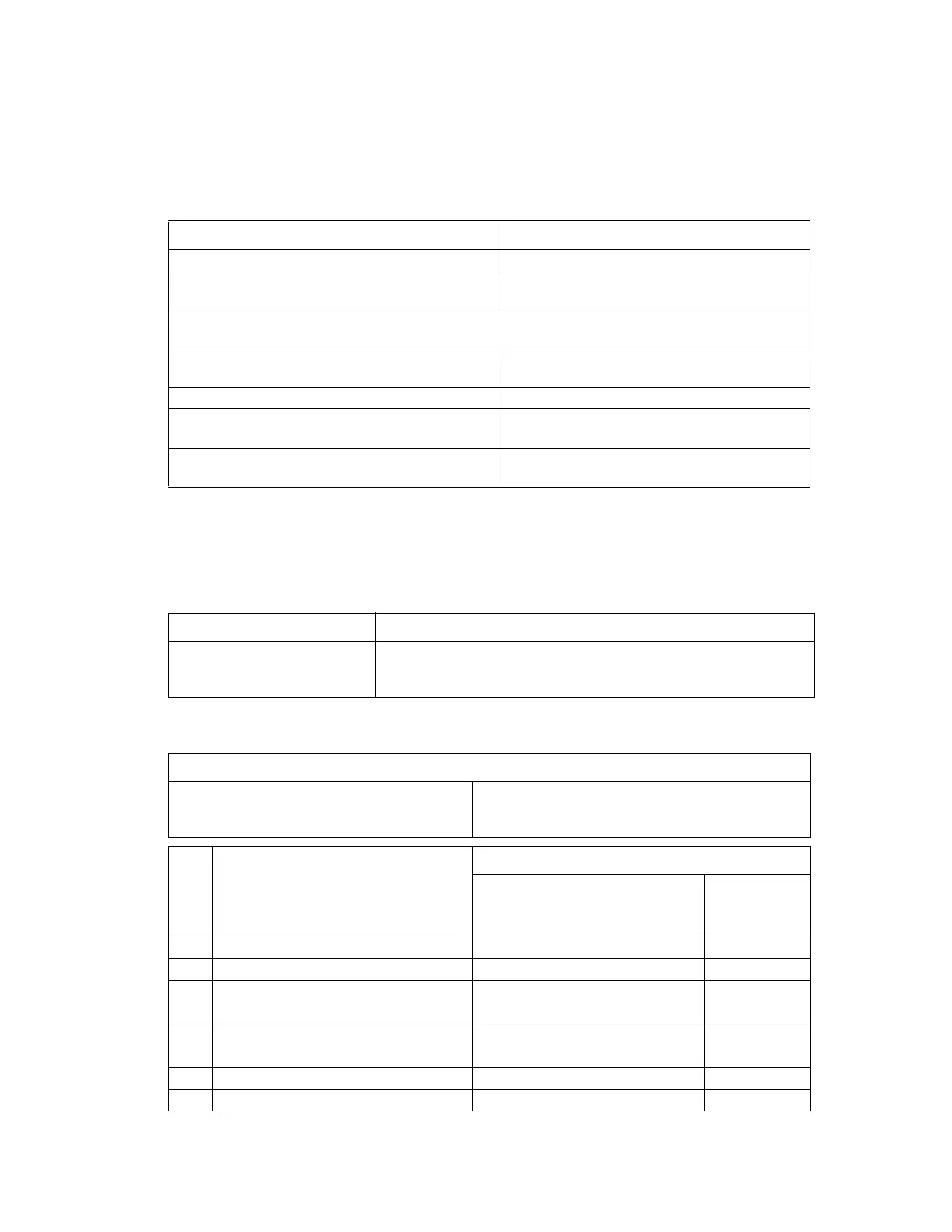

Check Item Action

Does the paper meet product specifications? Change the paper.

Is paper curled, wavy, or damp? Change the paper.

Instruct the user in correct paper storage.

Is a foreign object present along the paper path, or is

the paper path deformed or worn?

Clean or change the paper path.

Are the Paper Separator Fingers dirty, deformed, or

worn?

Clean or change the defective Paper Separator

Finger.

Are the rolls/rollers dirty, deformed, or worn? Clean or change the defective roll/roller.

Are the Edge Guide and Trailing Edge Stop at the

correct position to accommodate the paper?

Set as necessary.

Are the actuators found operational when checked

for correct operation?

Correct or change the defective actuator.

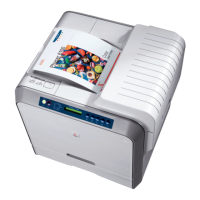

Type Description

Detection of misfeed at Duplex

Unit reverse drive/storage

section

The Duplex Transport Sensor (PC12 DU) is not unblocked within a

specified period of time after the Duplex Reverse Motor (M9 DU) has

been energized for reverse drive.

Relevant Electrical Parts

Duplex Transport Sensor (PC12 DU)

Duolex Transport Motor (M8 DU)

Duplex Reverse Motor (M9 DU)

Duplex Board (PWB-A DU)

PWB-A (Engine Control Board)

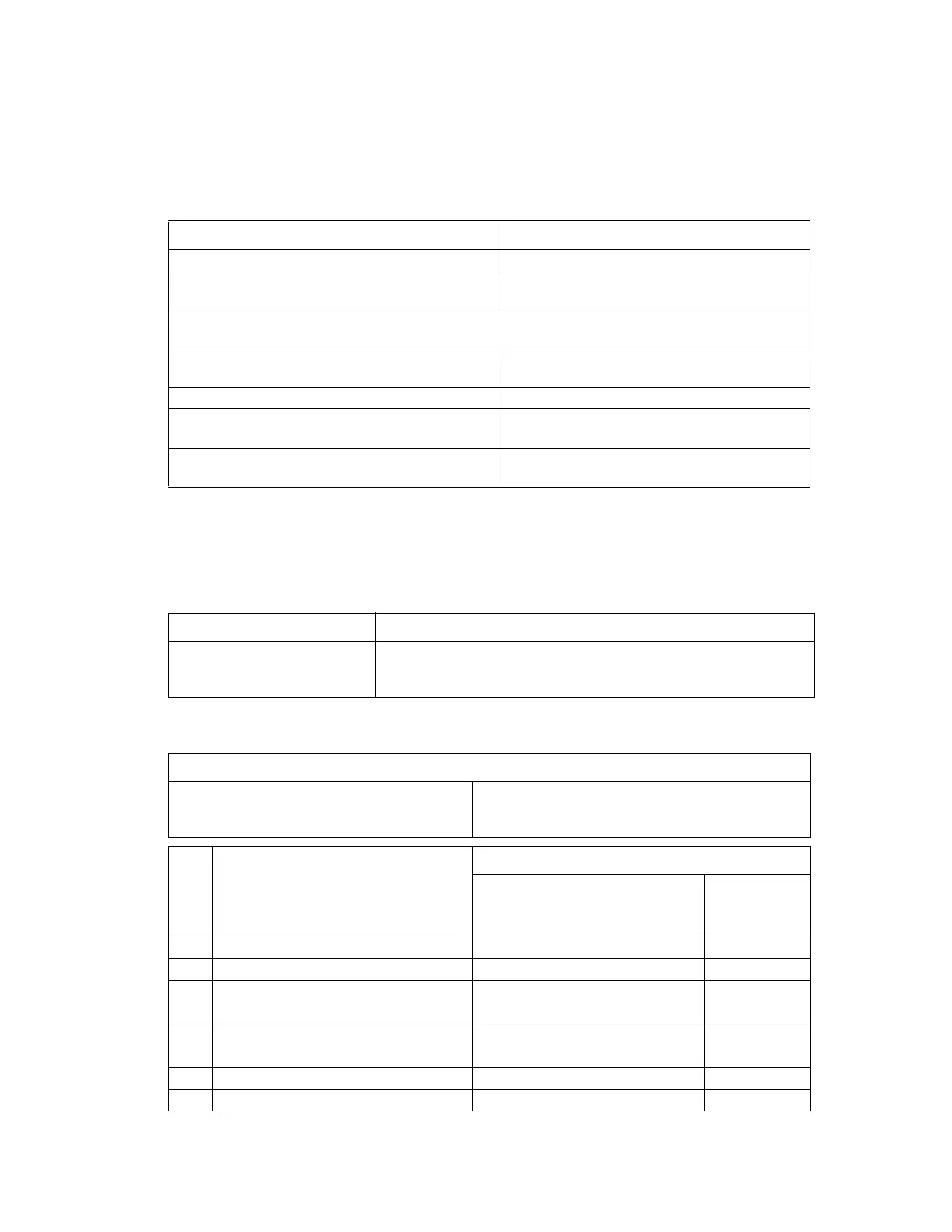

Step Action

WIRING DIAGRAM

Control Signal

Location

(Electrical

Component)

1 Initial check items. - -

2 Check the PC12 DU sensor. PWB-A DU PJ5A DU-3 (ON) 3-C

3 Check M8 DU for correct operation. PWB-A DU

PJ2A DU-1~4 (pulse)

5~6-C

4 Check M9 DU for correct operation. PWB-A DU

PJ2A DU-5~8 (pulse)

5~6-C~D

5 Change PWB-A DU. - -

6 Change PWB-A. - -

Loading...

Loading...