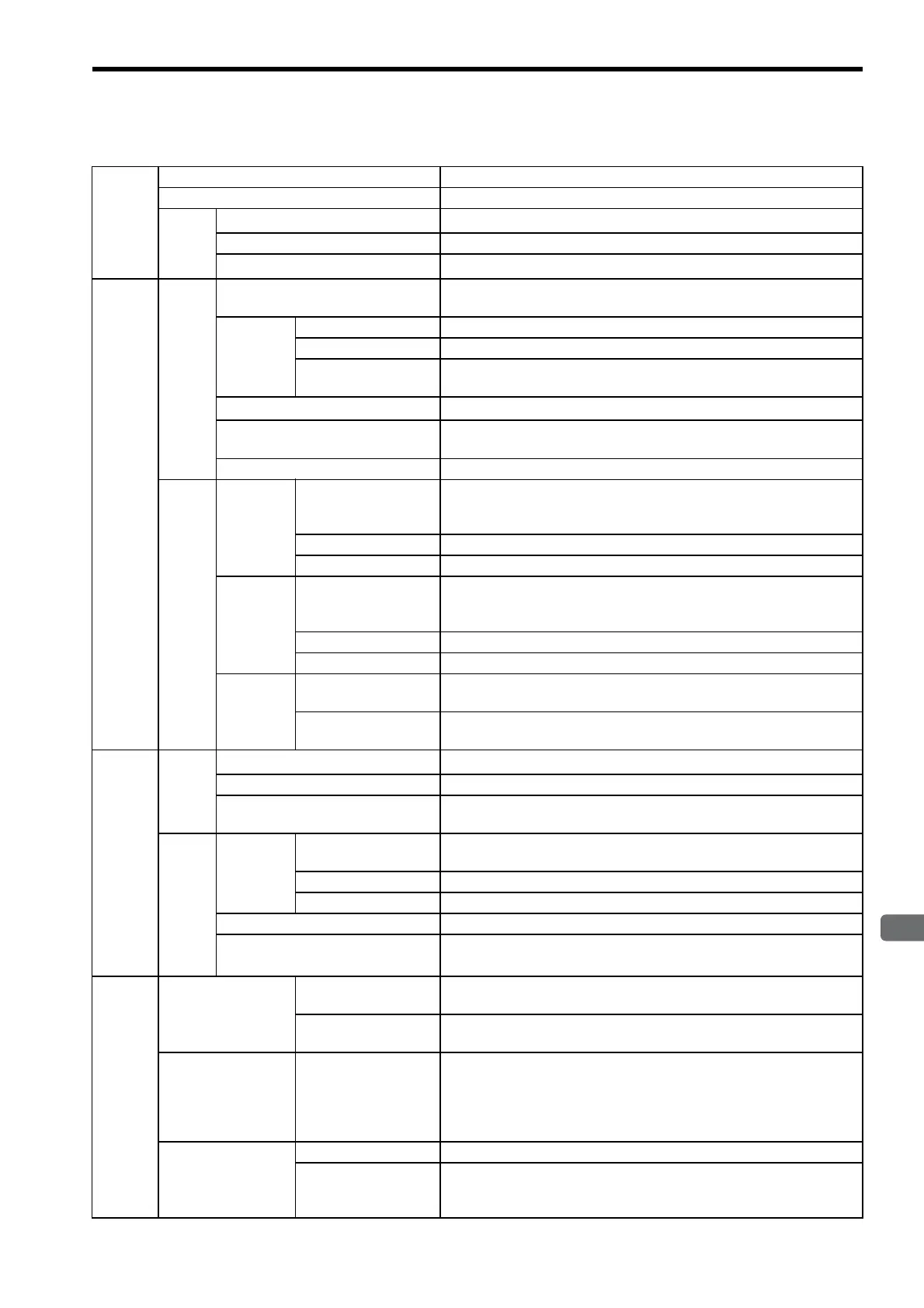

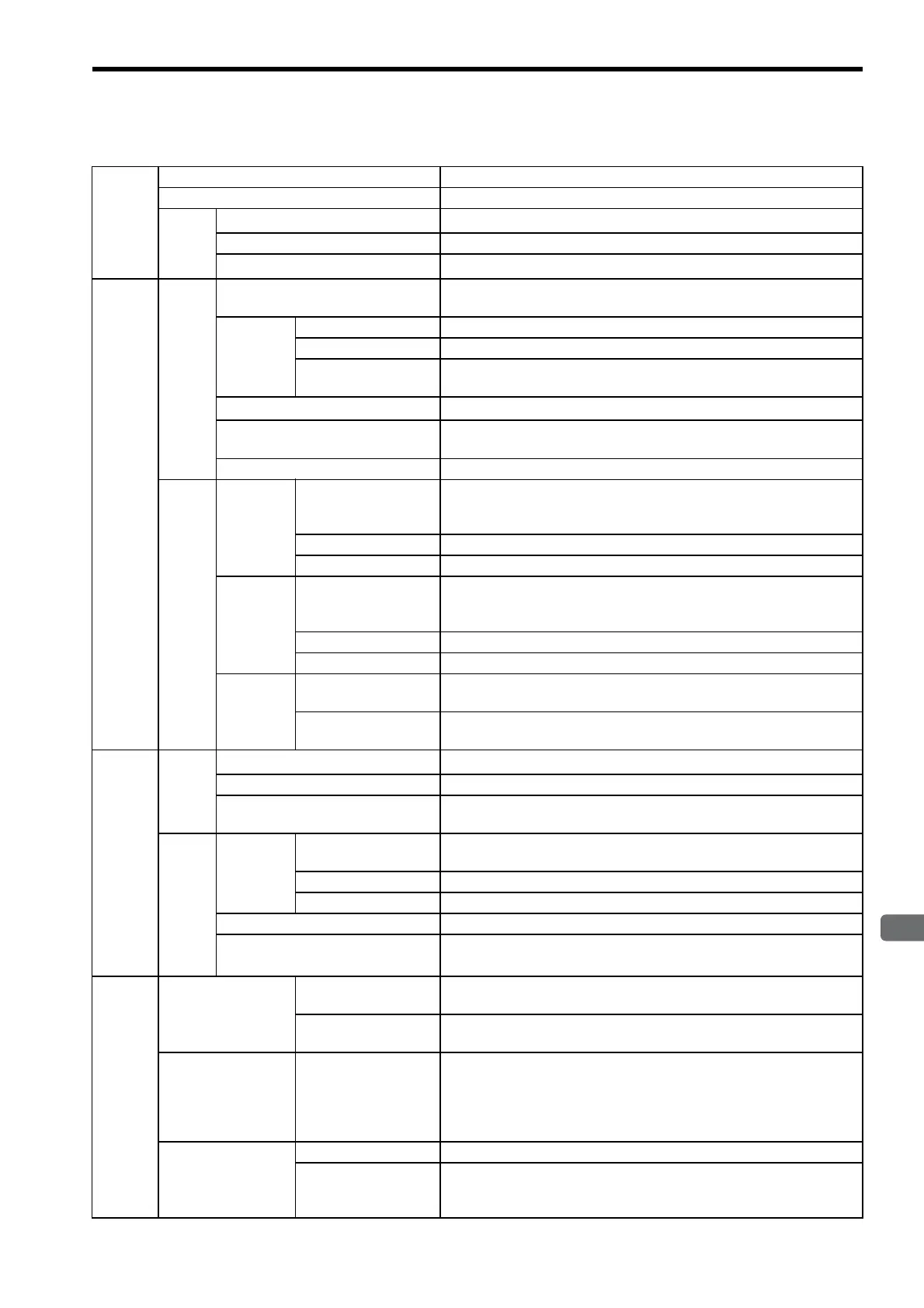

4.1 SERVOPACK Ratings and Specifications

4

SERVOPACK Specifications and Dimensional Drawings

4-3

4.1.3 SERVOPACK Ratings and Specific

ations

Basic

Specifi-

cations

Control Method Three-phase full-wave rectification IGBT-PWM (sine-wave driven)

Feedback Serial encoder: 17-bit (incremental/absolute)

Condi-

tions

Ambient/Storage Temperature

∗1

0 to +55°C/-20 to +85°C

Ambient/Storage Humidity 90% RH or less (with no condensation)

Vibration/Shock Resistance

4.9 m/s

2

/19.6 m/s

2

Speed

and

Torque

Control

Modes

Perfor-

mance

Speed Control Range 1:5000 (The lowest speed of the speed control range is the speed at which

the servomotor will not stop with a rated torque load.)

Speed

Regula-

tion

∗2

Load Regulation 0 to 100% load: ±0.01% or less (at rated speed)

Voltage Regulation Rated voltage ±10%: 0% (at rated speed)

Temperature Regula-

tion

25 ± 25°C: ±0.1% or less (at rated speed)

Frequency Characteristics 100 Hz (at J

L

= J

M

)

Torque Control Tolerance

(Repeatability)

±2%

Soft Start Time Setting 0 to 10 s (Can be set individually for acceleration and deceleration.)

Input

Signals

Speed

Reference

Input

Reference Voltage

∗3

±6 VDC (Variable setting range: ±2 to ±10 VDC) at rated speed, input

voltage: maximum ±12 V (servomotor forward rotation with positive

reference)

Input Impedance About 14 kΩ

Circuit Time Constant About 47 μs

Torqu e

Reference

Input

Reference Voltage

∗3

±3 VDC (Variable setting range: ±1 to ±10 VDC) at rated torque, input

voltage: maximum ±12 V (positive torque reference with positive

reference)

Input Impedance About 14 kΩ

Circuit Time Constant About 47 μs

Contact

Speed

Reference

Rotation Direction

Selection

With P control signal

Speed Selection With forward/reverse external torque limit signal (speed 1 to 3 selection),

servomotor stops or another control method is used when both are OFF.

Position

Control

Modes

Perfor-

mance

Bias Setting

0 to 450 min

-1

(setting resolution: 1 min

-1

)

Feed Forward Compensation 0 to 100% (setting resolution: 1%)

Positioning Completed Width

Setting

0 to 250 reference units (setting resolution: 1 reference unit)

Input

Signals

Reference

Pulse

Type Sign + pulse train, 90° phase difference 2-phase pulse train (phase A +

phase B), or CCW + CW pulse train

Form Line driver (+5 V level), open collector (+5 V or +12 V level)

Frequency Maximum 500/200 kpps (line driver/open collector)

Control Signal Clear signal (input pulse form identical to reference pulse)

Built-in Open Collector Power

Supply

∗4

+12 V (1kΩ resistor built in)

I/O

Signals

Position Output Form Phase-A, -B, -C line driver

Phase-S line driver (only with an absolute encoder)

Frequency Dividing

Ratio

Any

Sequence Input Signal allocation can

be modified.

Servo ON, P control (or Control mode switching, forward/reverse motor

rotation by internal speed setting, zero clamping, reference pulse prohib-

ited), forward run prohibited (P-OT), reverse run prohibited (N-OT),

alarm reset, forward external torque limit, and reverse external torque

limit (or internal speed selection)

Sequence Output Fixed Output Servo alarm, 3-bit alarm codes

Signal allocation can

be modified.

Select three signals from the following: Positioning completed (speed

coincidence), servomotor rotation detection, servo ready, torque limit,

speed limit, brake interlock, warning, NEAR signal.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...