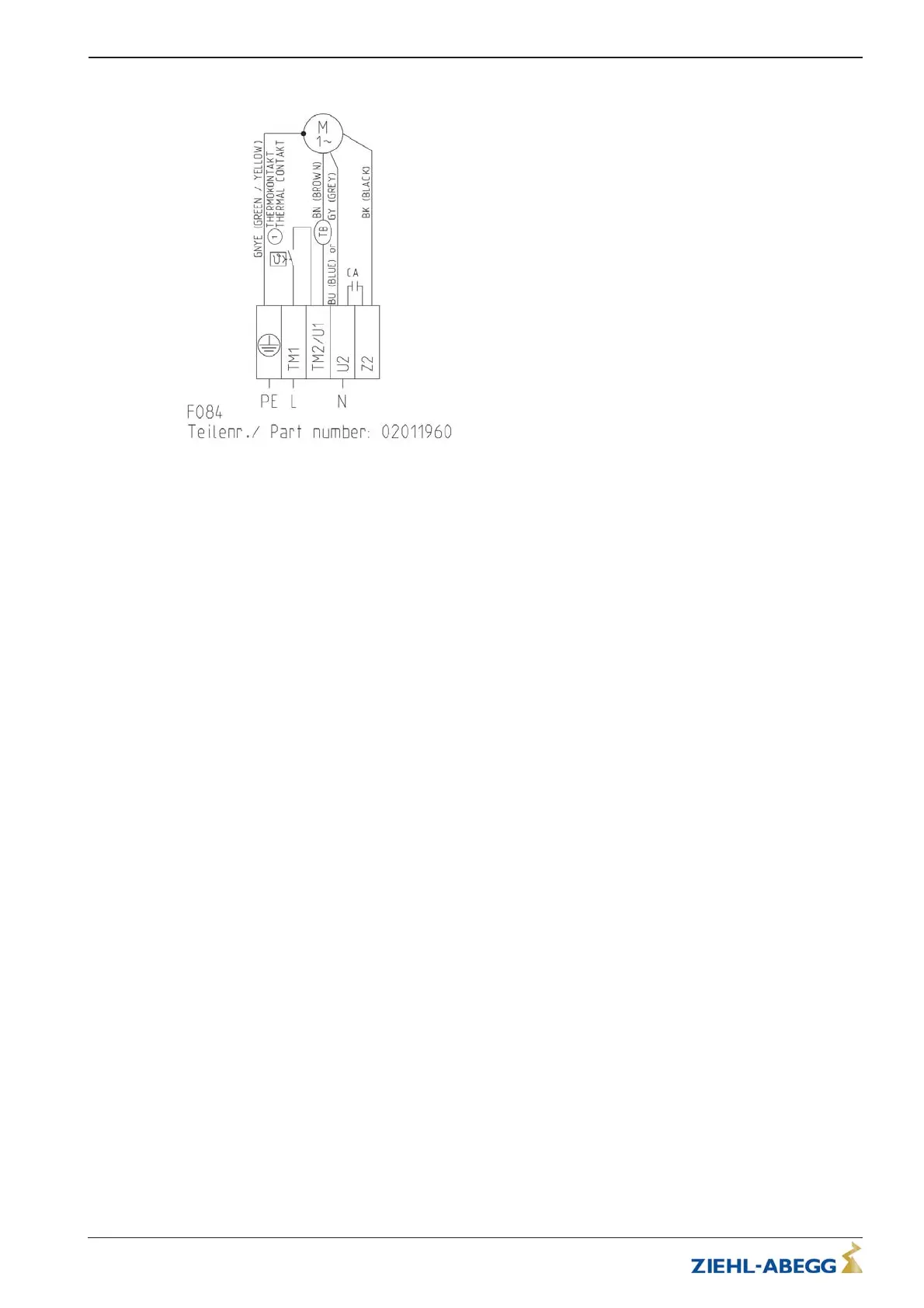

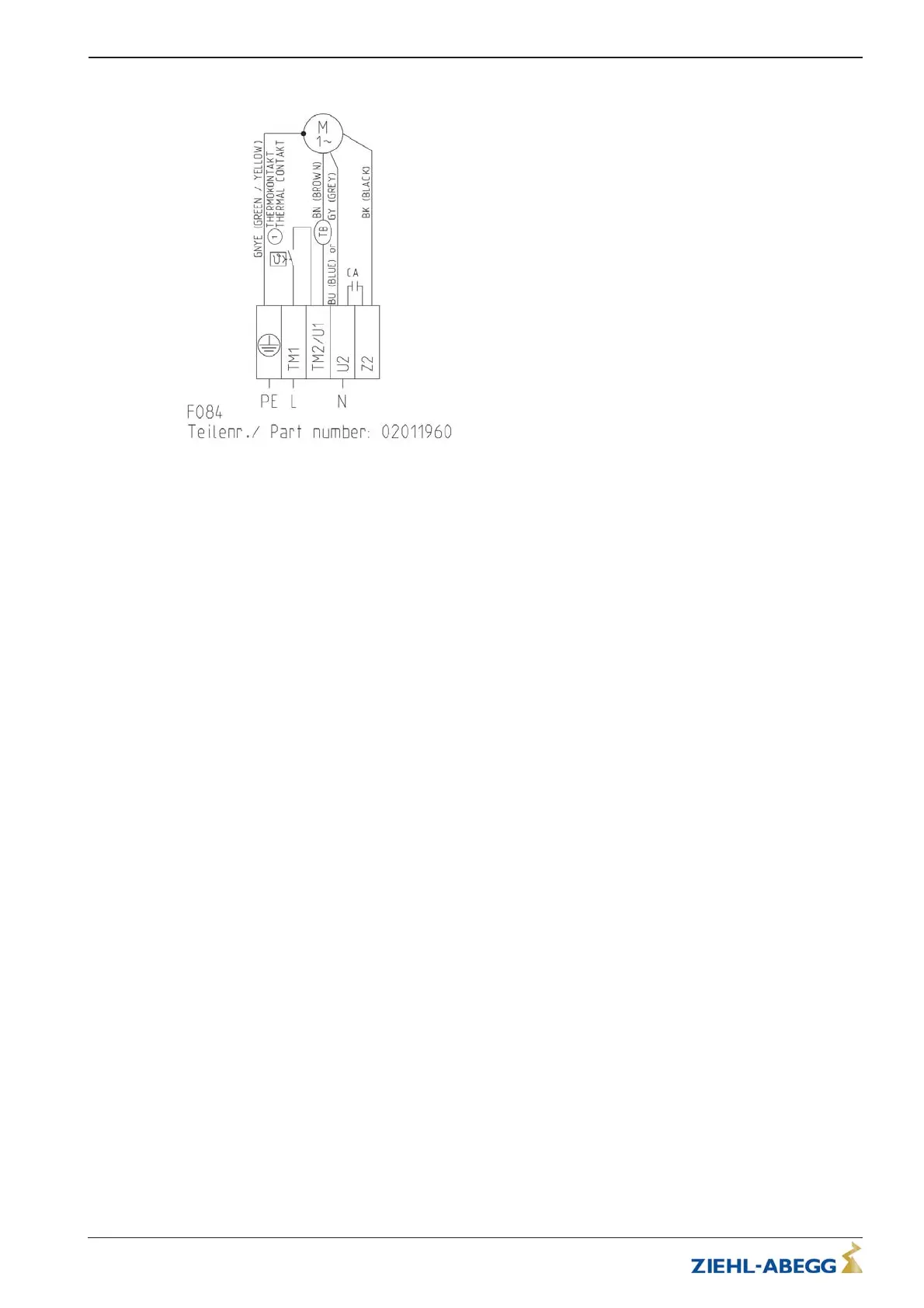

5.6.2 Connection diagram

1 Thermal contact

6 Start-up

6.1 Operating conditions

The elevator machine must be installed in a not free accessible machine room or a closed hoist-

way.

Be aware of the protection class specified on the name plate.

Do not operate the elevator machine in an explosive atmosphere.

Please contact ZIEHL-ABEGG SE in case of orders deviating from the corresponding application

conditions.

6.2 First Start-up

Before first-time start-up, check the following:

Installation and electrical connection have been properly completed.

Safety devices are installed.

All leftover installation materials and other foreign materials have been removed.

The protective earth is connected.

Motor protection correctly connected and operative.

Cable entries closed.

Mounting, installation position and accessories are o.k.

Connection data corresponds to the data on the name plate.

6.3 Tests

Tests on elevator systems can be performed by the assembly company or a certification authority or

organisation. This involves discovering of failure-critical and hazardous conditions. The relevant

operator is responsible for safety. The descriptions below are intended as recommendations for the

technical procedure and do not deal in sufficient depth with safety engineering aspects of the relevant

system. Therefore, priority is given to the safety engineering specifications of the assembly company

or operator. Only trained specialist personnel may carry out tests.

6.3.1 Half load test with current measurement

The test for the 50 % weight compensation should preferably be carried out as follows:

The motor current is to be measured in both travel directions with a half load.

The measured currents should correspond as closely as possible.

The difference between the measured currents should not show a variation of more than 10 %.

Translation of the original operating instructions

ZAtop – model series SM210.60B/SM210.70B Start-up

$7%$B*% ,QGH[ Part.-No. 01013389-GB (EU-BD 1014)

21/88

Loading...

Loading...