6.5.4 Automatic emergency evacuation

The automatic emergency evacuation is described in the operation instructions of the control, the

frequency inverter and, if available, an evacuation unit with UPS.

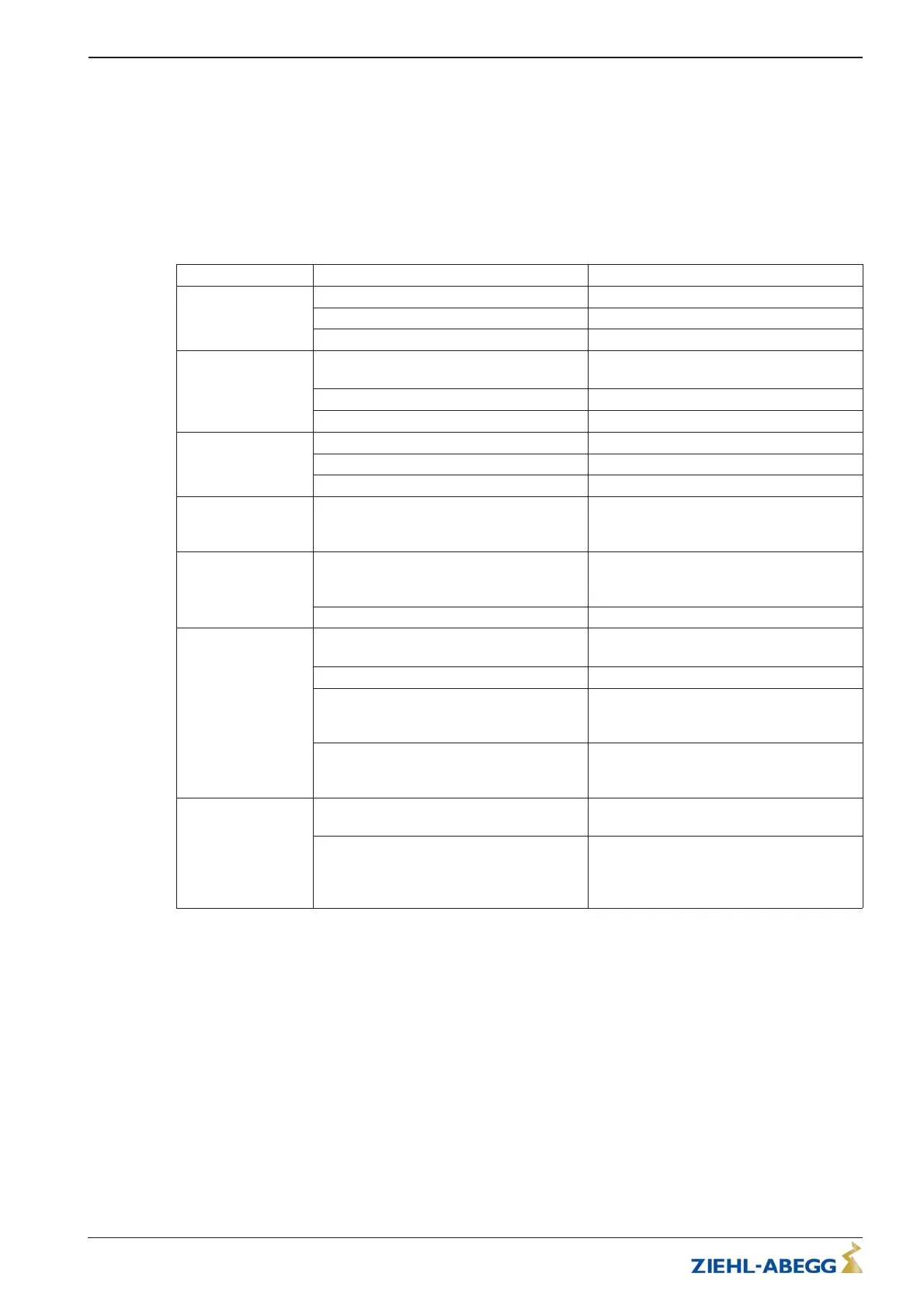

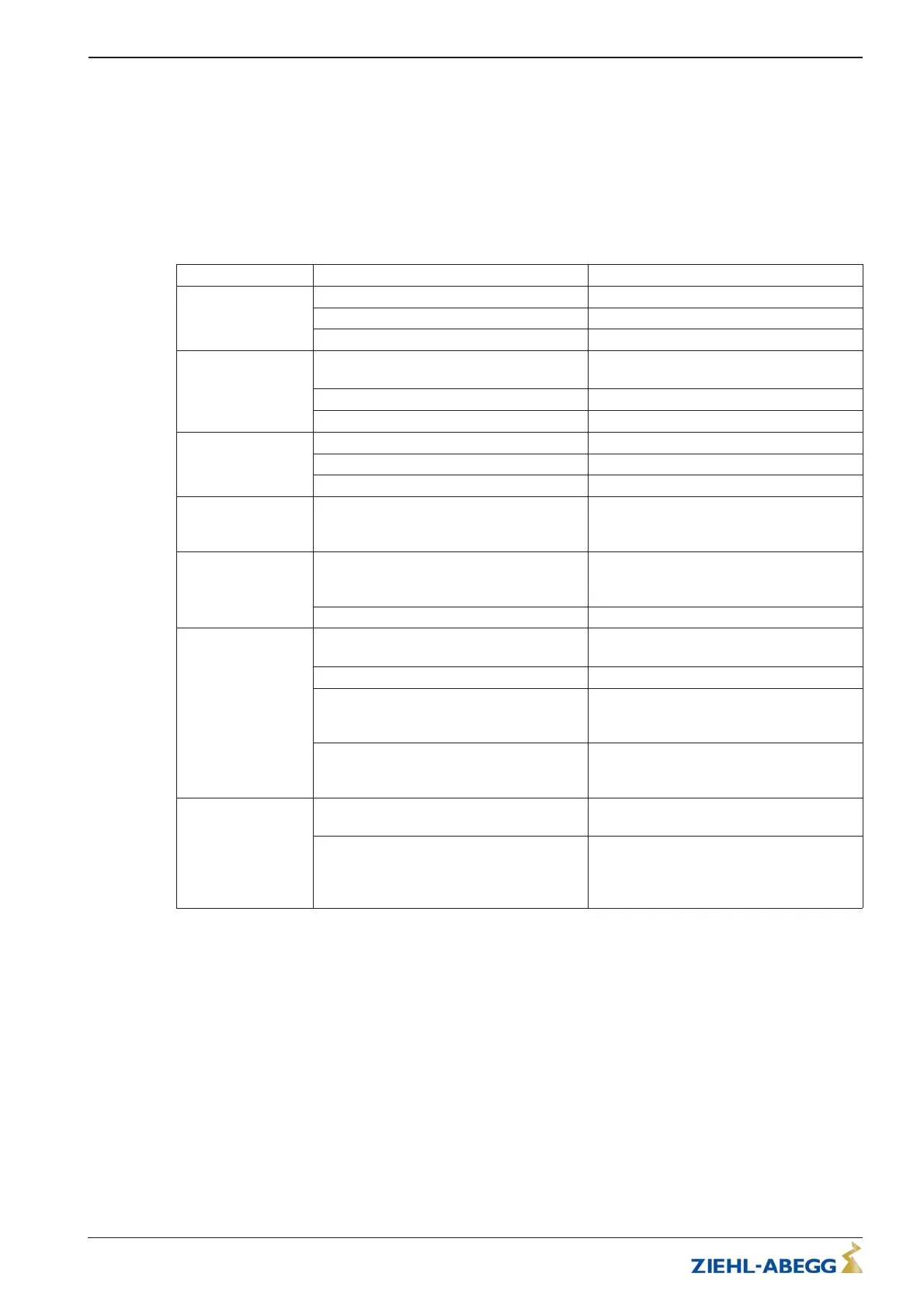

7 Faults and remedy

Excessive temperature / Temperature protection trips

Failure Causes Adjustment

Noises on elevator

machine

Bearing defective Contact customer service

Wrong setting at the frequency inverter Check setting at the frequency inverter

Absolute encoder defective Change absolute encoder

Excessive tempera-

ture / Temperature

protection trips

Surface of the elevator machine is covered Remove cover from drive or mount with

more distance to the elevator machine.

Ambient temperature higher than 40 °C Enhance shaft ventilation

Wrong setting at the frequency inverter Check setting at the frequency inverter

Elevator machine

does not start

Motor phases connected incorrect Check motor connection

VVVF defective Check VVVF

Brake does not release See brake faults

Elevator machine

does not turn with a

bleed brake

Brake block sticks after a long storage time

on the rotor

Bleed or remove the brake and release the

brake block carefully from the rotor.

Brake switching

noises

Brake is switched on the DC-side Modify the control to AC switching for nor-

mal operation. Fit an additional protective

circuit.

Air gap of brake too big Replacing the brake blocks

Brake does not re-

lease

Power supply too low. The voltage at the

brake is to low.

Check supply, if necessary increase cable

cross-section (and transformer)

Brake control wrong / defective Check brake control

Brake coil defective Replace brake (special tool required.

ZIEHL-ABEGG SE Contact customer serv-

ice).

Brake worn out Replace brake blocks (special tool required.

ZIEHL-ABEGG SE Contact customer serv-

ice).

Brake release moni-

toring does not

switch

Microswitch/inductive proximity switch de-

fective

Replace microswitch/inductive proximity

switch

Contacts dirty Operate microswitch/inductive proximity

switch with a higher contact current, at least

10 mA or replace microswitch/inductive

proximity switch or brake

8 Service and maintenance

8.1 General notes on maintenance

Observe the safety-at-work regulations!

Disassembling the elevator machine can only be done with special devices!

Caution, strong magnetic force!

Never use a high-pressure cleaner (for example steam jet cleaner) for cleaning the elevator

machine!

Take note of abnormal operating noise.

The bearings have a lifetime lubrication. There is no possibility to relubricate. Maintenance is not

necessary for the bearings.

Translation of the original operating instructions

ZAtop – model series SM210.60B/SM210.70B Faults and remedy

$7%$B*% ,QGH[ Part.-No. 01013389-GB (EU-BD 1014)

24/88

Loading...

Loading...