5. Tighten the fixing screws (2) with a torque wrench with an allen screw SW 14 uniformly in steps:

- Tightening torque step 1: 70 Nm

- Tightening torque step 2: 120 Nm

-Tightening torque step 2: 195 Nm

6. Endue the fixing screws (2) with locking paint.

7. Fit rope guard (1), see chapter "Mechanical installation - fastening of rope guard".

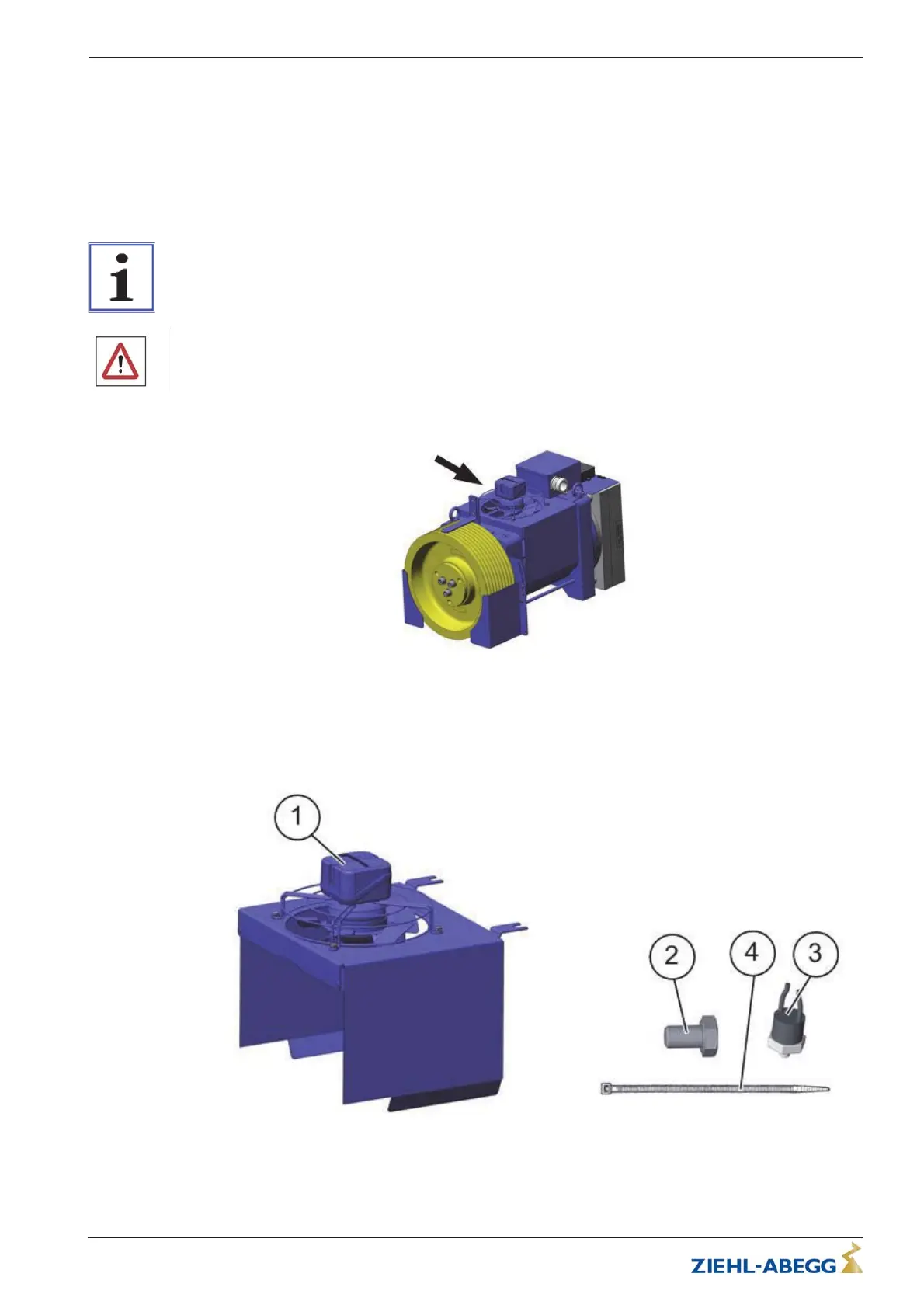

8.3.4 Replacement of the bearing bracket

The

mounting and dismounting of the magnet rotor and the flange bearing bracket must only be

carried out by qualified personnel and with special devices in the factory.

Warning!

The drawbars of the elevator machine must not be released under any circumstances.

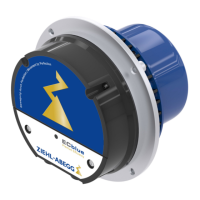

8.3.5 Retrofittiing the forced ventilation

8.3.5.1 Required tools for the retrofitting of the forced ventilation:

•

Screw wrench SW 19

8.3.5.2 Scope of delivery

Translation of the original operating instructions

ZAtop – model series SM210.60B/SM210.70B Service and maintenance

$7%$B*% ,QGH[ Part.-No. 01013389-GB (EU-BD 1014)

40/88

Loading...

Loading...