Appendix: Process PID control

What this chapter contains

The chapter contains instructions on quick configuration of the process control, gives

an application example and describes the PID sleep functionality.

Process PID control

There is a built-in PID controller in the drive. The controller can be used to control

process variables such as pressure, flow or fluid level. In process PID control, a

process reference (setpoint) is set with drive's integrated potentiometer. An actual

value (process feedback) is connected to the drive's analog input. The process PID

control adjusts the drive speed in order to keep the measured process quantity

(actual value) at the desired level (setpoint).

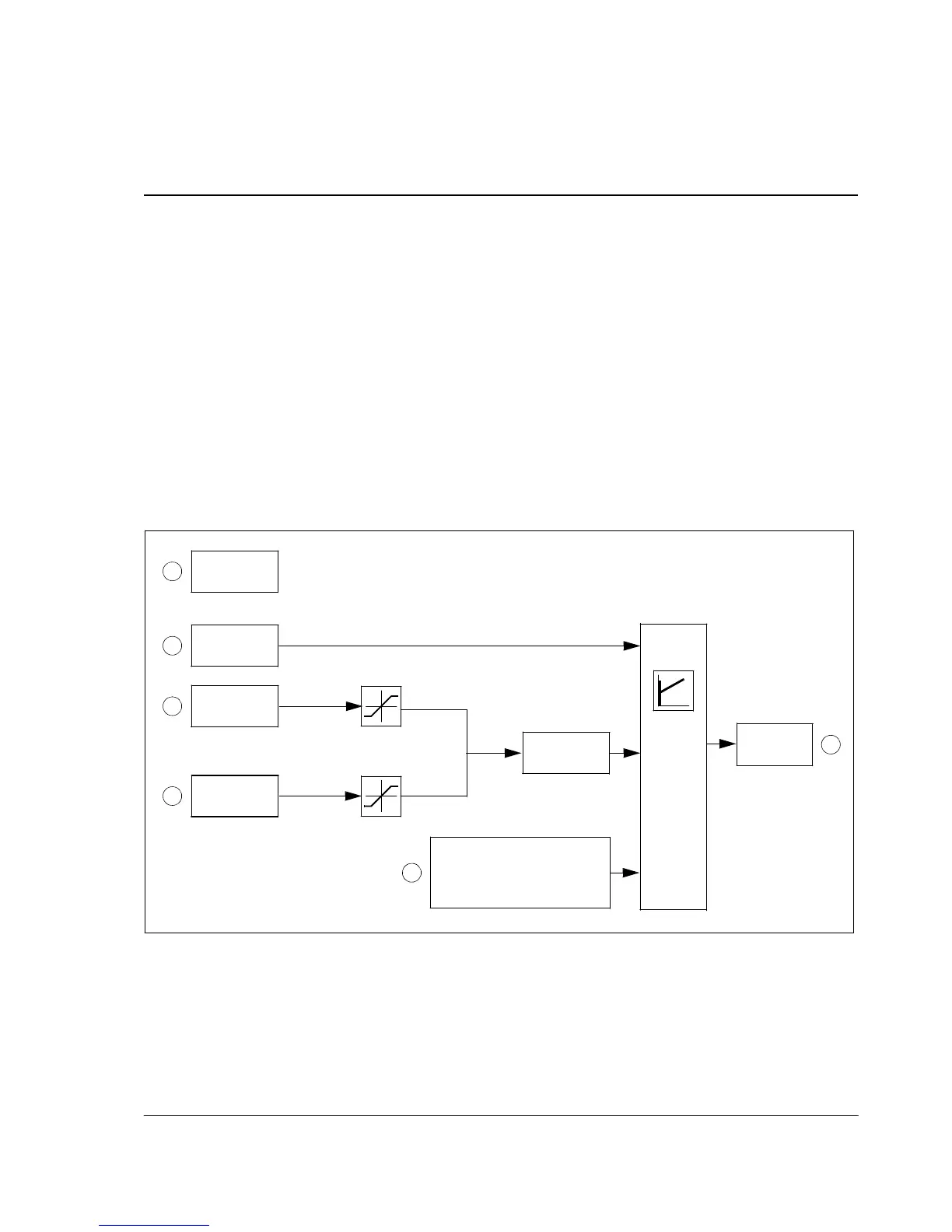

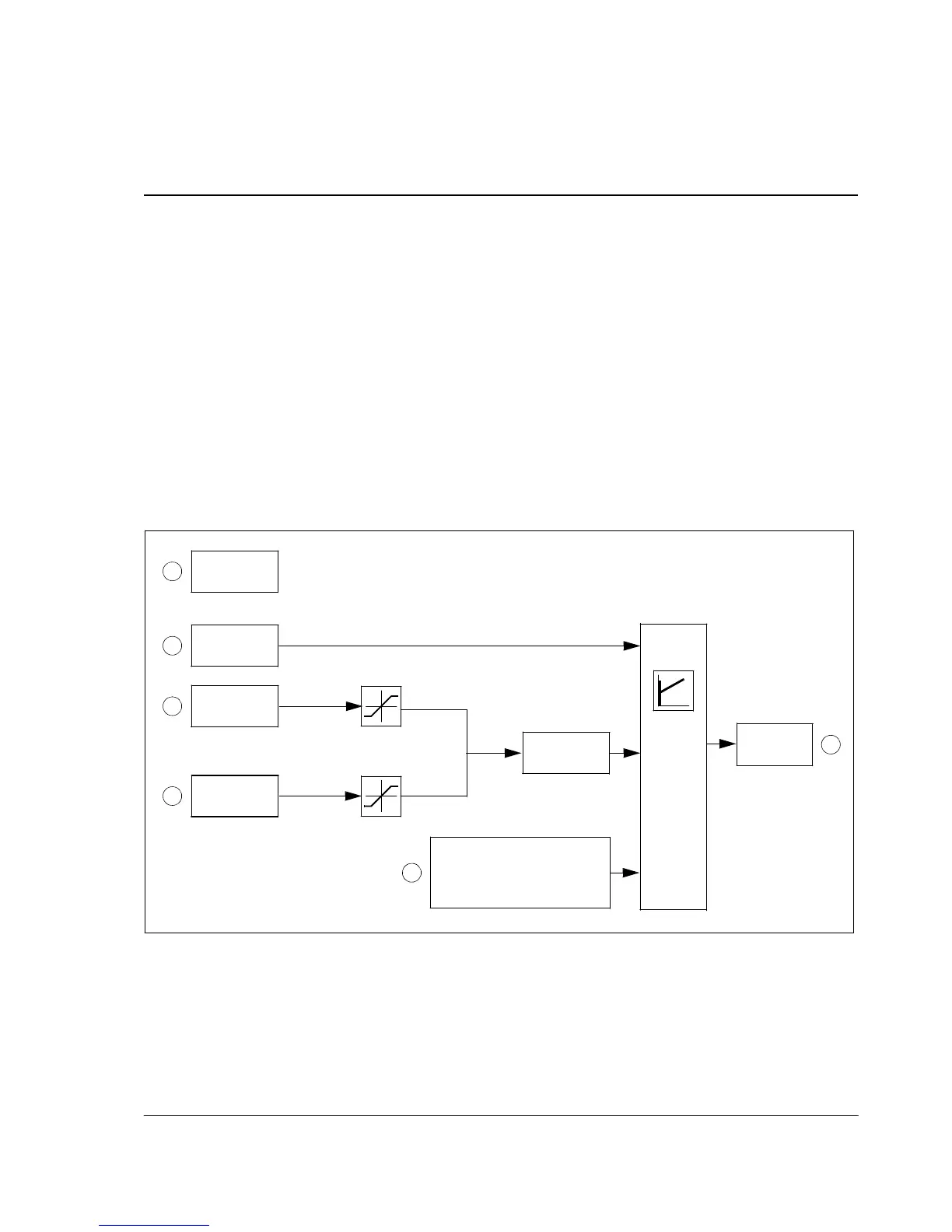

Quick configuration of process PID control

9902 APPLIC

1

MACRO

4010 SET

2

POINT SEL

Process

PID

4018 ACT1

MINUMUM

4016 ACT1

3

INPUT

4019 ACT1 MAXIMUM

4019 AC

T1

MAXIMUM

4017 ACT2

4

INPUT

4018 ACT1 MINIMUM

4021 ACT2 MAXIMUM

4020 ACT2 MINUMUM

4001 GAIN

4014 FBK

SEL

PID output

6

4002 INTEGRATION

TI

ME

5

4003 DERIVATION

TIME

4005 ERROR VALUE

INV

1. 9902 APPLIC MACRO: Set 9902 APPLICATION MACRO to 6 (PID CONTROL).

2. 4010 SET POINT SEL: Determine the source for the PID reference signal (PID

setpoint) and define its scale (4006 UNITS, 4007 UNIT SCALE).

3. 4014 FBK SEL and 4016 ACT1 INPUT: Select the process actual value

(feedback signal) for the system and configure feedback levels (4018 ACT1

MINUMUM, 4019 ACT1 MAXIMUM).

Loading...

Loading...