PID sleep functionality

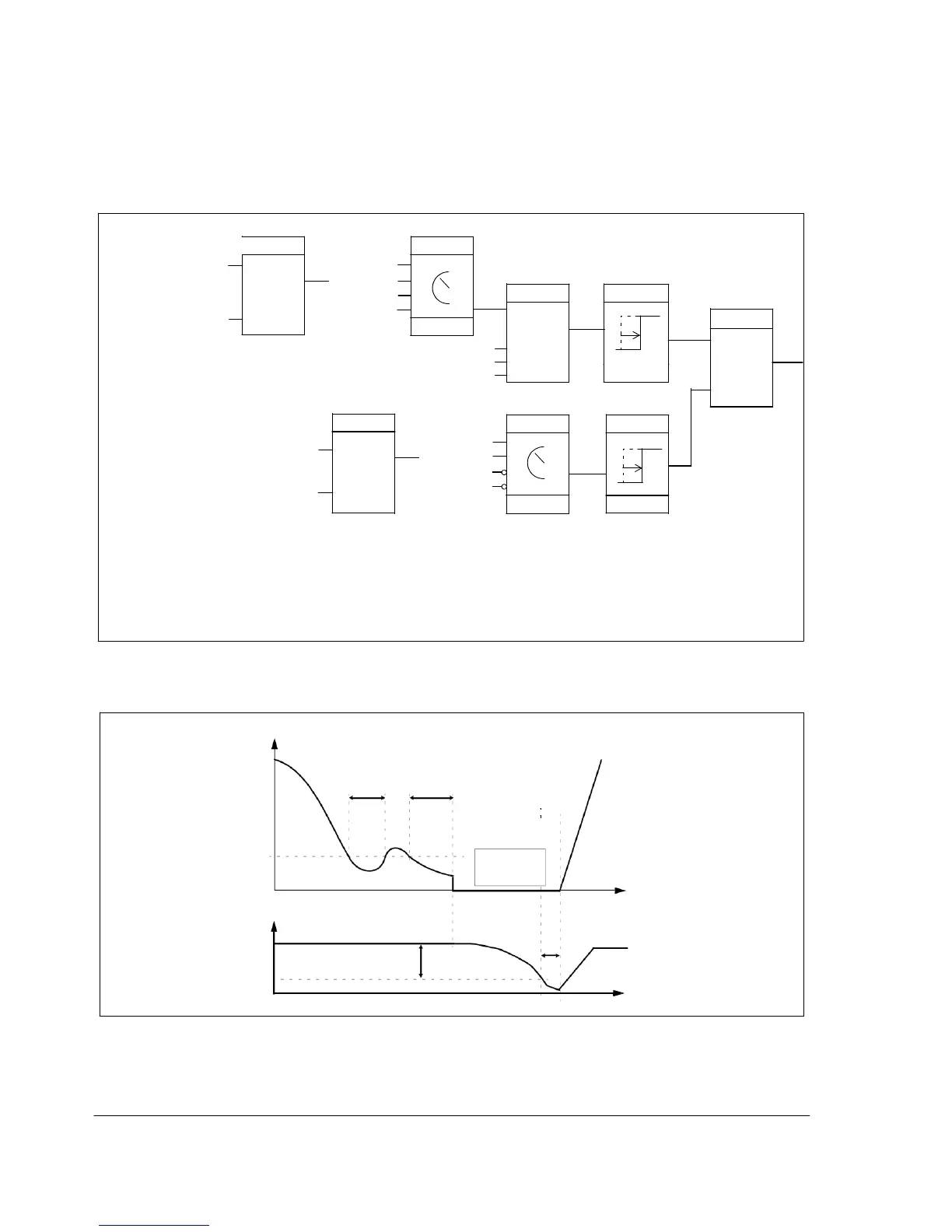

The block diagram below illustrates the sleep function enable/disable logic. The

sleep function can be put into use only when the PID control is active.

output

frequency

Compare

1

NOT SEL

INTERNAL

Select

1<2

DI1

And

.

Delay

4023

2

.

4022

%refActive

&

PIDCtrlActive

modulating

t

4024

Set/Reset

S

S/R

1)

R

0132

Compare

1

1>2

NOT SEL

INTERNAL

D

I

.

1

.

Select

Delay

t

4025

2

.

4022 4026

1) 1 = Activate sleeping

0 = Deactivate sleeping

%refActive: The % reference (EXT REF2) is in use. See parameter 1102 EXT1/EXT2 SEL.

PIDCtrlActive: Parameter 9902 APPLIC MACRO = 6 (PID CONTROL).

modulating: Drive IGBT control is operating.

Example

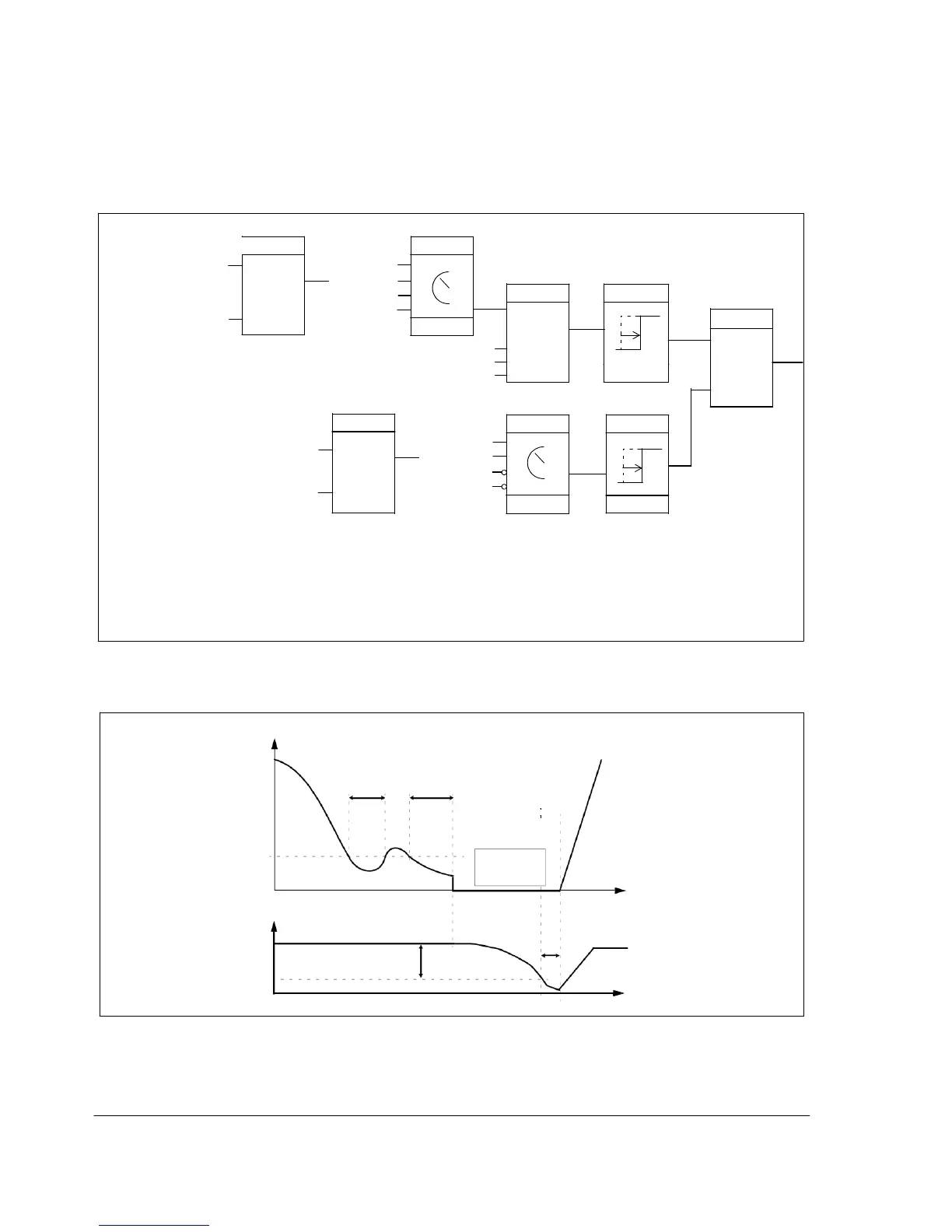

The time scheme below visualizes the operation of the sleep function.

Motor speed

t

d

= Sleep delay (4024)

t<t

d

t

d

Sleep

level

(4023

)

Actual value

Wake-up deviation

(4025)

Control panel

display

:

PID

S

L

EEP

t

Stop

St

ar

t

Wake-up delay

(4026)

t

Loading...

Loading...