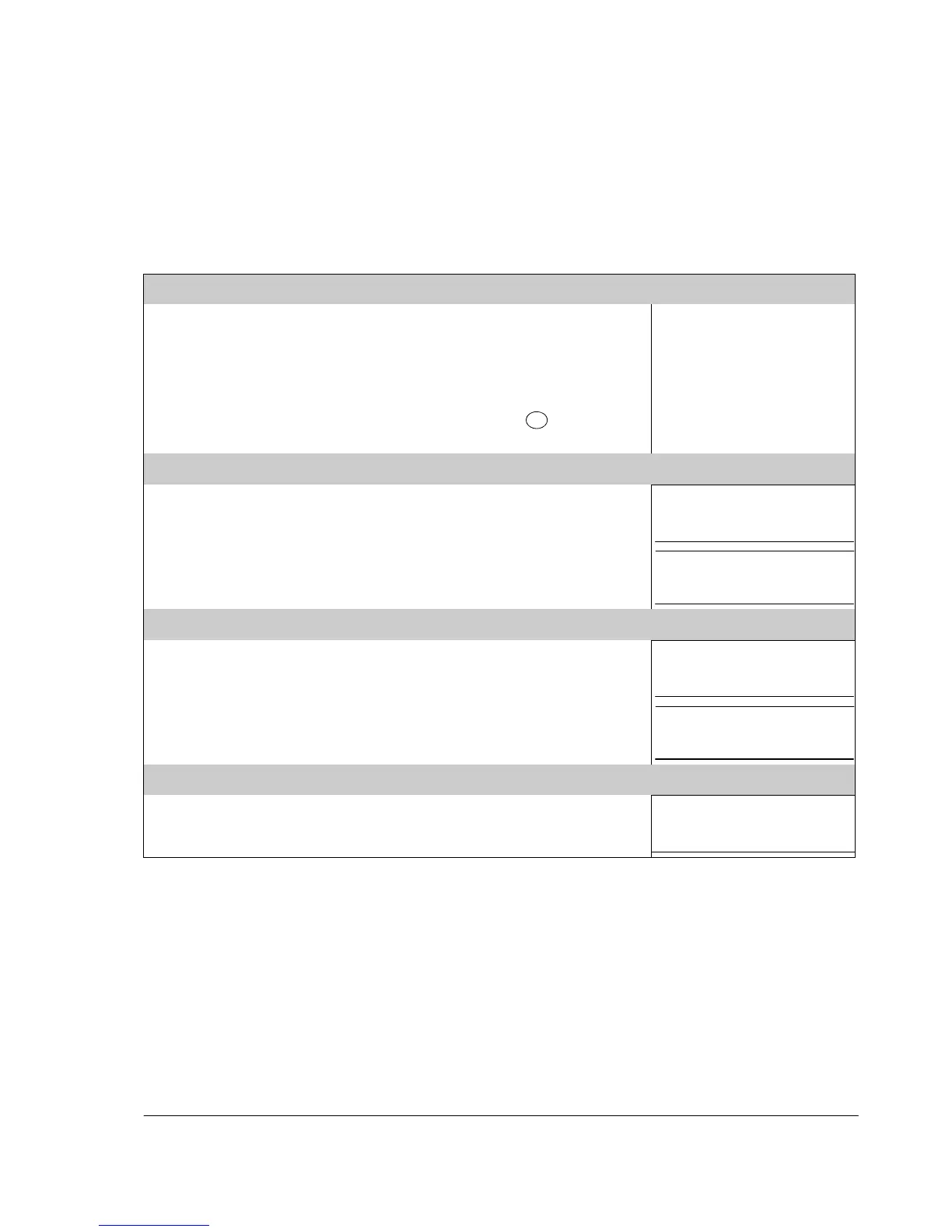

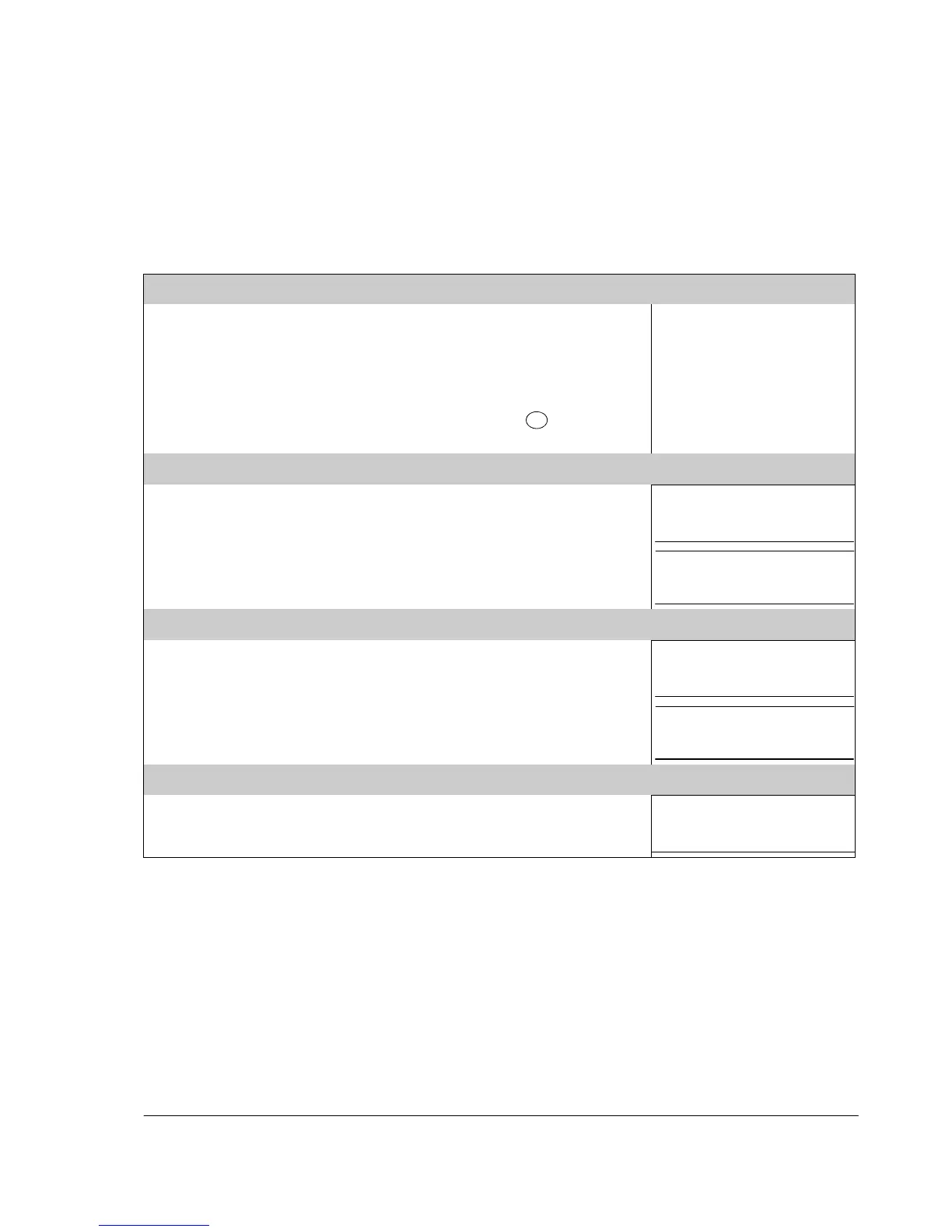

Start-up and control with I/O

How to control the drive through the I/O interface

The table below instructs how to operate the drive through the digital and analog

inputs when:

• the motor start-up is performed, and

• the default (standard) parameter settings are valid.

If you need to change the direction of rotation, check that parameter

1003 DIRECTION is set to 3 (REQUEST).

Ensure that the control connections are wired according to the

connection diagram given for the ABB standard macro.

Ensure that the drive is in remote control. Press key

LOC

to switch

REM

between remote and local control.

See Default I/O connection

diagram on page 46.

In remote control, the panel

display shows text REM.

STARTING AND CONTROLLING THE SPEED OF THE MOTOR

Start by switching digital input DI1 on.

Text FWD starts flashing fast and stops after the setpoint is reached.

Regulate the drive output frequency (motor speed) by adjusting the

voltage or current of the analog input AI(1).

REM

0

.

0

Hz

OUTPUT FWD

REM

50

.

0

Hz

OUTPUT FWD

CHANGING THE DIRECTION OF THE MOTOR ROTATION

Reverse direction: Switch digital input DI2 on.

Forward direction: Switch digital input DI2 off.

REM

50

.

0

Hz

OUTPUT REV

REM

50

.

0

Hz

OUTPUT FWD

Switch digital input DI1 off.

The motor stops and text FWD starts flashing slowly.

Loading...

Loading...