Actual signals and parameters

Parameters in the Long parameter mode

Sets the maximum display value for the signal selected by parameter 3415

SIGNAL3 PARAM. See parameter 3402 SIGNAL1 MIN.

Setting range depends on parameter 3415 SIGNAL3 PARAM setting.

Process PID (PID1) control parameter set 1.

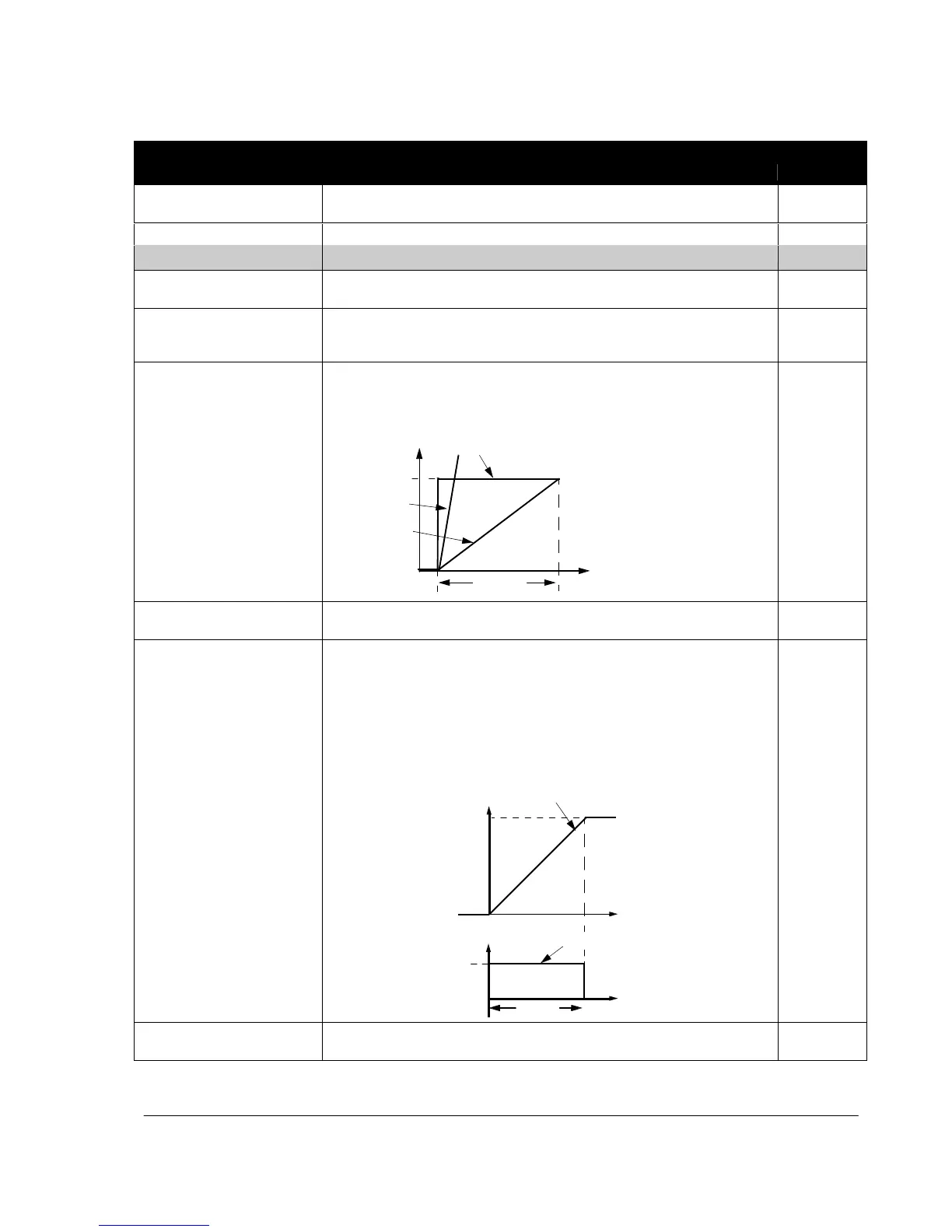

Defines the gain for the process PID controller. High gain may cause speed

oscillation.

Gain. When value is set to 0.1, the PID controller output changes one-tenth

as much as the error value. When value is set to 100, the PID controller

output changes one hundred times as much as the error value.

Defines the integration time for the process PID1 controller. The integration

time defines the rate at which the controller output changes when the error

value is constant. The shorter the integration time, the faster the continuous

error value is corrected. Too short an integration time makes the control

unstable.

A

A = Error

B

B = Error value step

C = Controller output with gain = 1

D (4001 = 10)

D = Controller output with gain = 10

C (4001 = 1)

t

4002

Integration time. If parameter value is set to zero, integration (I-part of the

PID controller) is disabled.

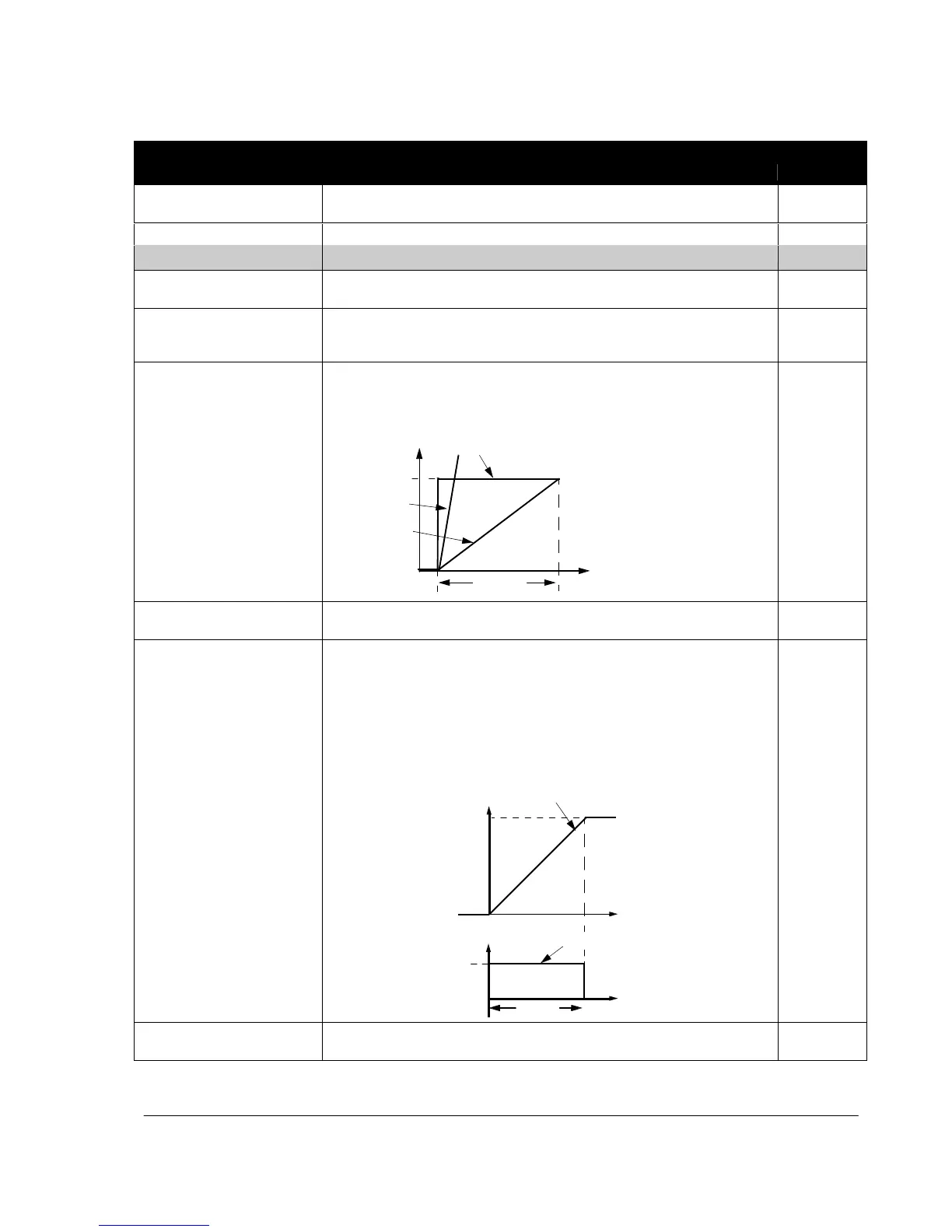

Defines the derivation time for the process PID controller. Derivative action

boosts the controller output if the error value changes. The longer the

derivation time, the more the speed controller output is boosted during the

change. If the derivation time is set to zero, the controller works as a PI

controller, otherwise as a PID controller.

The derivation makes the control more responsive for disturbances.

The derivative is filtered with a 1-pole filter. Filter time constant is defined by

parameter 4004 PID DERIV FILTER.

Error

Process error value

100%

0%

t

PID output

D-part of controller ou

tput

Gain

4001

4003

Derivation time. If parameter value is set to zero, the derivative part of the

PID controller is disabled.

Loading...

Loading...