2 Machine Synchronization

2.9.3. I/O signals

773HAC18154-1 Revision: F

© Copyright 2004-2008 ABB. All rights reserved.

2.9.3. I/O signals

Overview

Sensor Synchronization provides several I/O signals which allow a user or RAPID program

to monitor and control the object queue on the encoder interface unit. The object queue is

designed for the option Conveyor Tracking and has more functionality than required by

Sensor Synchronization. Since each closing of a press is considered an object in the object

queue, signals for the object queue may occasionally be useful.

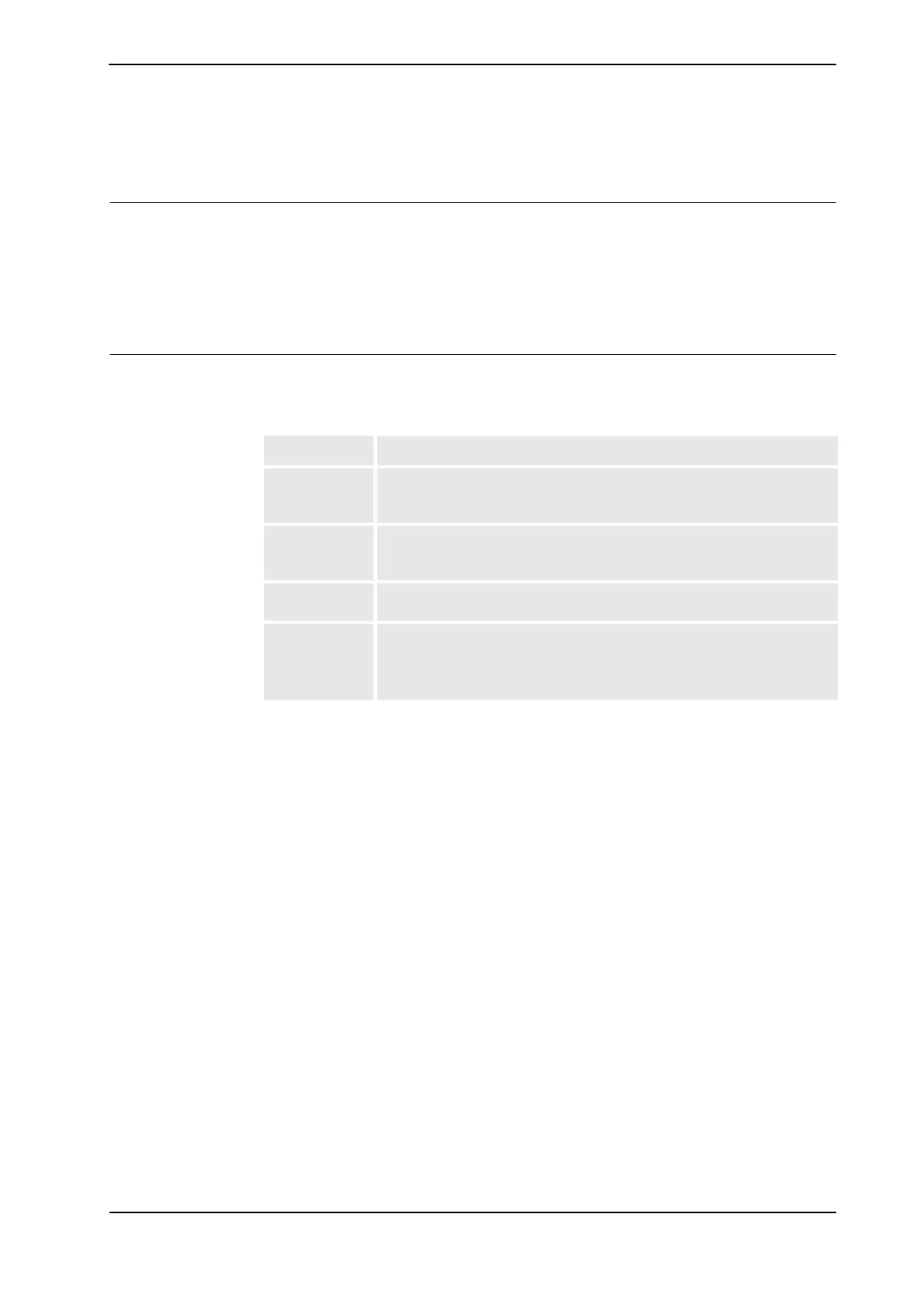

Object queue signals

The following table shows the I/O signals in the encoder unit DSQC 354 which impact the

object queue.

Instruction Description

c1ObjectsInQ Group input showing the number of objects in the object queue. These

objects are registered by the synchronization switch and have not been

dropped.

c1Rem1PObj Digital output that removes the first pending object from the object queue.

Pending objects are objects that are in the queue but are not connected to

a work object.

c1RemAllPObj Digital output that removes all pending objects. If an object is connected,

then it is not removed.

c1DropWObj Digital output that will cause the encoder interface unit to drop the tracked

object and disconnect it. The object is removed from the queue.

Do not use c1DropWObj in RAPID code. Use the DropWobj instruction

instead.

Loading...

Loading...