Common attributes for Motion instructions

664 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

For example:

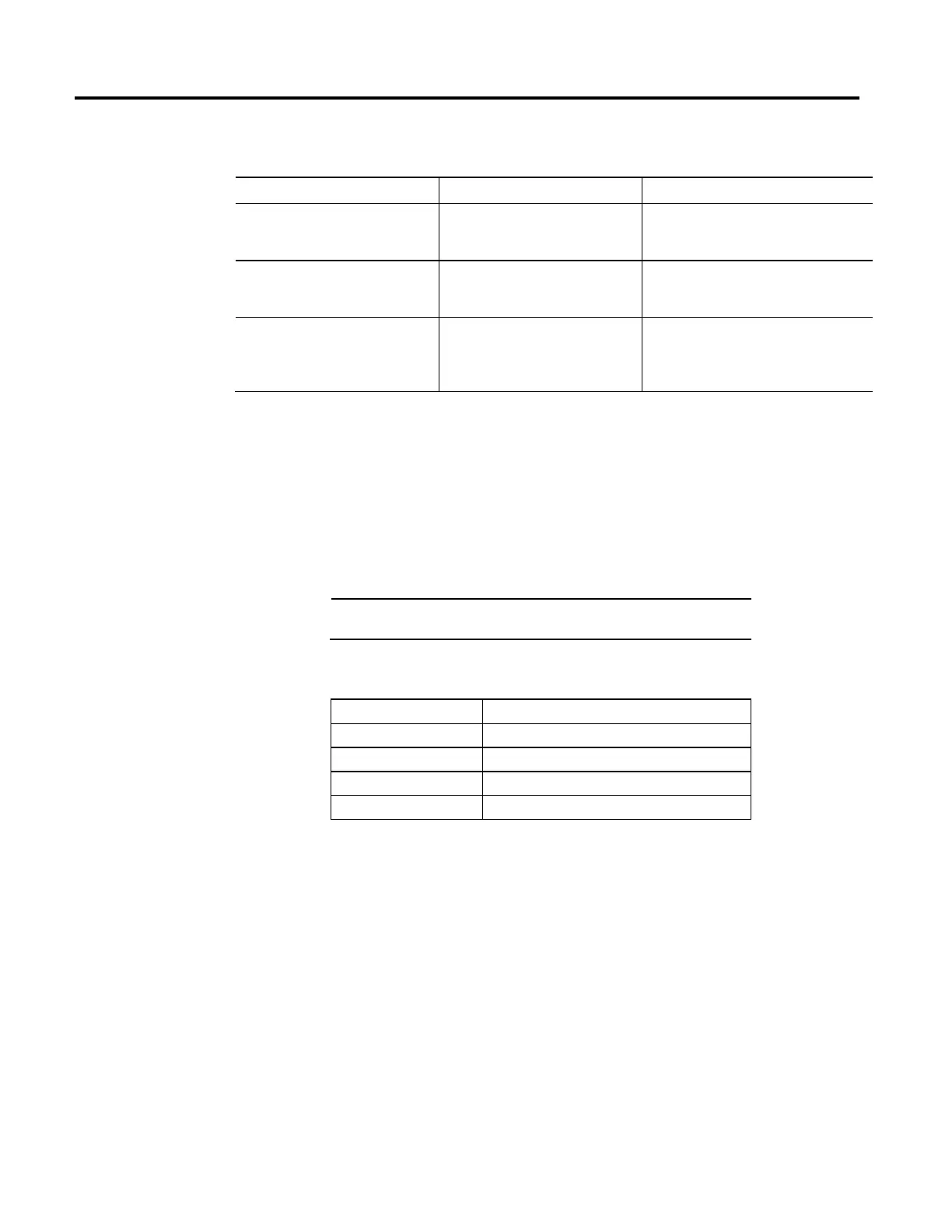

Definitions Example Description

my_list defined as DINT[10] my_list[5] This example references element 5 in the array. The

reference is static because the subscript value

remains constant.

my_list defined as DINT[10]

position defined as DINT

MOV the value 5 into position

my_list[position]

This example references element 5 in the array. The

reference is dynamic because the logic can change

the subscript by changing the value of position.

my_list defined as DINT[10]

position defined as DINT

offset defined as DINT

MOV the value 2 into position

MOV the value 5 into offset

my_list[position+offset]

This example references element 7 (2+5) in the

array. The reference is dynamic because the logic

can change the subscript by changing the value of

position or offset.

Make sure any array subscript you enter is within the boundaries of the specified

array. Instructions that view arrays as a collection of elements generate a major

fault (type 4, code 20) if a subscript exceeds its corresponding dimension.

When you enter an immediate value (constant) in decimal format (for example,

-2, 3) the controller stores the value by using 32 bits. If you enter a value in a radix

other than decimal, such as binary or hexadecimal, and do not specify all 32 bits,

the controller places a zero in the bits that you do not specify (zero-fill).

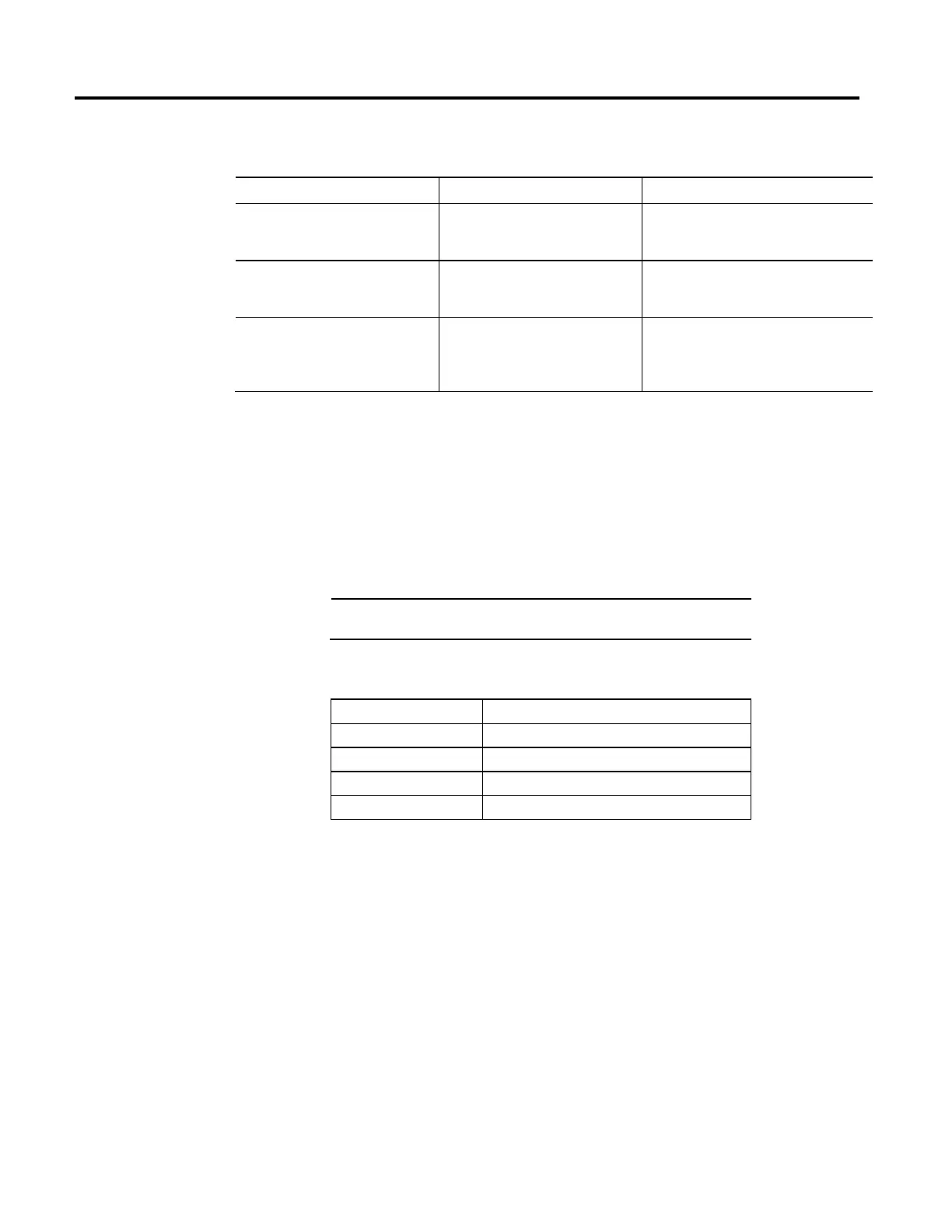

Important:

Zero-fill of immediate binary, octal or hexadecimal values less than 32

bits.

If you enter The controller stores

-1 16#ffff ffff (-1)

16#ffff (-1) 16#0000 ffff (65535)

8#1234 (668) 16#0000 029c (668)

2#1010 (10) 16#0000 000a (10)

Logix controllers handle floating point values according to the IEEE 754 standard

for floating-point arithmetic. This standard defines how floating point numbers

are stored and calculated. The IEEE 754 standard for floating point math was

designed to provide speed and the ability to handle very large numbers in a

reasonable amount of storage space.

A REAL tag stores a single-precision, normalized floating-point number

Denormalized numbers and -0.0 are treated as 0.0

If a computation results in a NAN value, the sign bit could be positive or negative.

In this situation, the software displays 1#.NAN with no sign.

Loading...

Loading...