DO NOT HIT THE BALLS AND/OR THE INTERNAL RING.

CHECK THAT ALL PARTS ARE IN GOOD CONDITION, ESPECIALLY THOSE LISTED AS FOL-

LOWS.

SWINGARM BEARINGS

Carry out the check with the bearings fitted on the swingarm.

ROTATION CHECK

•

Manually rotate the inside ring of each bearing. Rotation must be constant, smooth and

noiseless.

If one or both bearings do not fall within the control parameters:

•

Replace both swingarm bearings.

RADIAL AND AXIAL CLEARANCE CHECK

•

Check the radial and axial clearance.

Axial clearance: a minimum axial clearance is allowed.

Radial clearance: none.

If one or both bearings do not fall within the control parameters:

•

Replace both swingarm bearings.

ALWAYS REPLACE BOTH BEARINGS.

ALWAYS REPLACE THE BEARINGS WITH OTHERS OF THE SAME TYPE.

SWINGARM SEALS

•

Check that the gaskets are in good conditions; replace them if they show signs of damage

or excessive wear.

ALWAYS REPLACE BOTH GASKETS.

ALWAYS REPLACE THE GASKETS WITH OTHERS OF THE SAME TYPE.

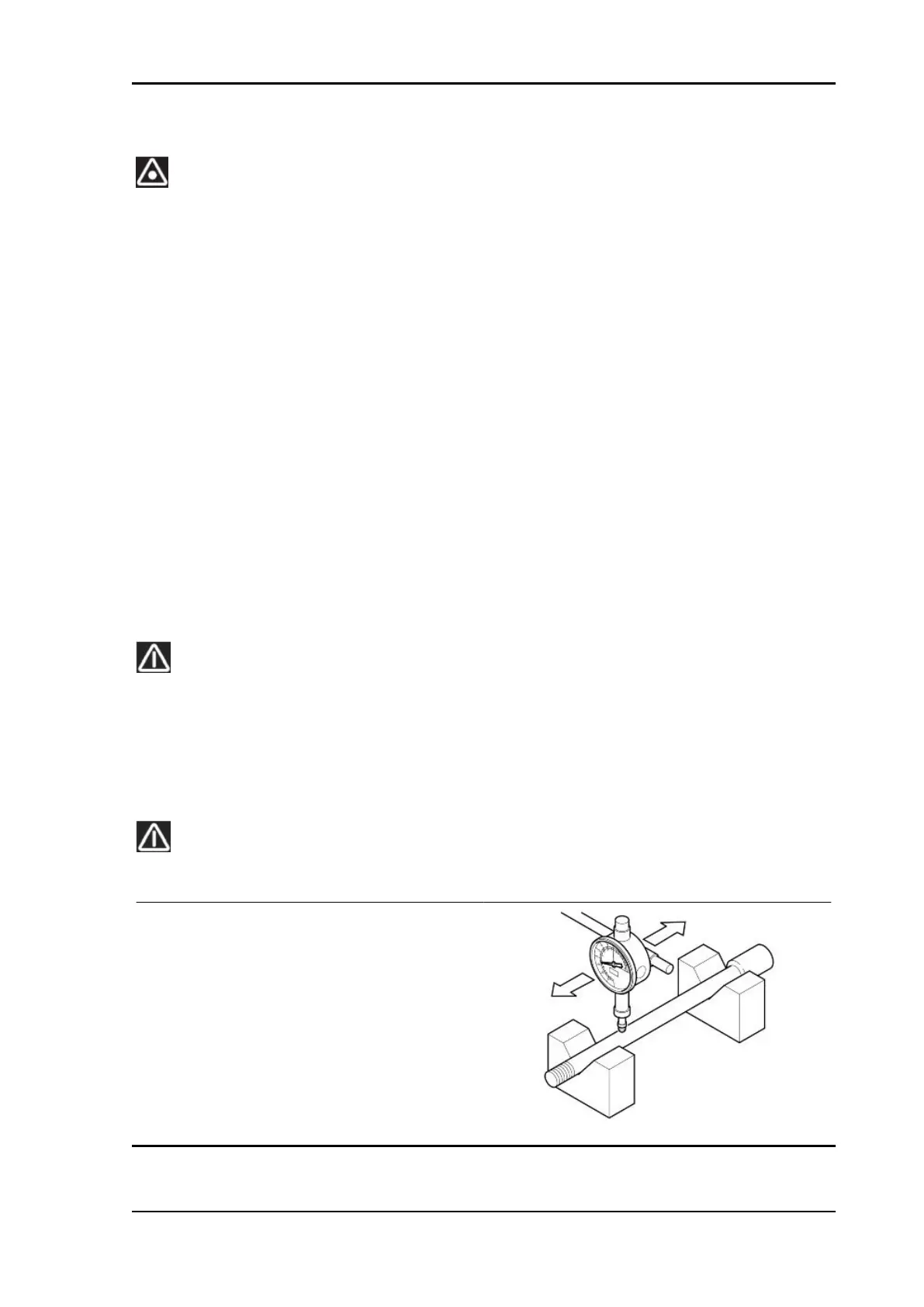

SWINGARM PIN

•

Use a dial gauge to check the swing-

arm pin eccentricity. If the eccentricity

exceeds the limit value, replace the

swingarm pin.

Maximum eccentricity: 0.3 mm (0.012 in)

TUONO V4 R Chassis

CHAS - 403

Loading...

Loading...