Figure 2.2 Jumper between Terminal 12/13 (24 V) and 37

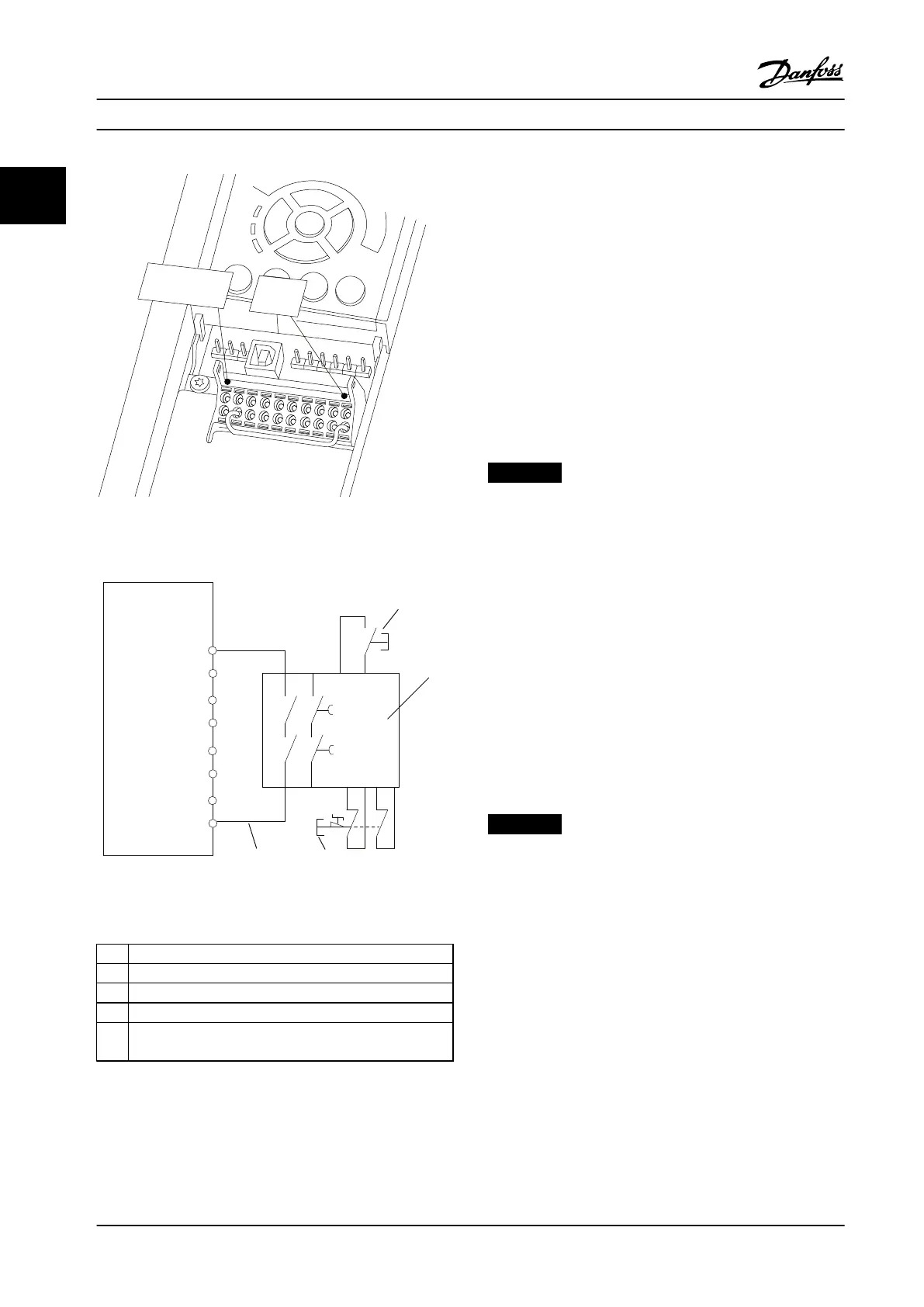

Figure 2.3 Installation to Achieve a Stopping Category 0 (EN

60204-1) with Cat. 3 /PL “d” (ISO 13849-1) or SIL 2 (EN 62061).

1 Frequency converter

2 [Reset] key

3 Safety relay (cat. 3, PL d or SIL2

4 Emergency stop button

5 Short-circuit protected cable (if not inside installation IP54

cabinet)

Table 2.2 Legend to Figure 2.3

Safe Torque O Commissioning Test

After installation and before rst operation, perform a

commissioning test of the installation using Safe Torque

O. Moreover, perform the test after each modication of

the installation.

Example with STO

A safety relay evaluates the E-Stop button signals and

triggers an STO function on the frequency converter in the

event of an activation of the E-Stop button (See Figure 2.4).

This safety function corresponds to a category 0 stop

(uncontrolled stop) in accordance with IEC 60204-1. If the

function is triggered during operation, the motor runs

down in an uncontrolled manner. The power to the motor

is safely removed, so that no further movement is possible.

It is not necessary to monitor plant at a standstill. If an

external force eect can occur, provide additional measures

to prevent any potential movement (for example

mechanical brakes).

NOTICE!

For all applications with Safe Torque O it is important

that short circuit in the wiring to T37 can be excluded.

Exclude the short circuit as described in EN ISO 13849-2

D4 by the use of protected wiring (shielded or

segregated).

Example with SS1

SS1 corresponds to a controlled stop, stop category 1

according to IEC 60204-1 (see Figure 2.5). When activating

the safety function, the frequency converter performs a

normal controlled stop. This can be activated through

terminal 27. After the safe delay time has expired on the

external safety module, the STO will be triggered and

terminal 37 will be set low. Ramping down as congured

in the frequency converter. If the frequency converter is

not stopped after the safe delay time, the activation of STO

will coast the frequency converter.

NOTICE!

When using the SS1 function, the brake ramp of the

frequency converter is not monitored with respect to

safety.

Example with Category 4/PL e application

Where the safety control system design requires two

channels for the STO function to achieve Category 4/PL e,

implement one channel via Safe Torque O T37 (STO) and

the other by a contactor. Connect the contactor in either

the frequency converter input or output power circuits and

controlled by the Safety relay (see Figure 2.6). The

contactor must be monitored through an auxiliary guided

contact, and connected to the reset input of the Safety

Relay.

Paralleling of Safe Torque O input the one Safety Relay

Safe Torque O inputs T37 (STO) may be connected

directly if it is required to control multiple frequency

converters from the same control line via one Safety Relay

Safety Instructions and Gen...

VLT

®

Compressor Drives CDS 302/CDS 303

10 Danfoss A/S © Rev. 2013-07-03 All rights reserved. MG34M422

22

Loading...

Loading...