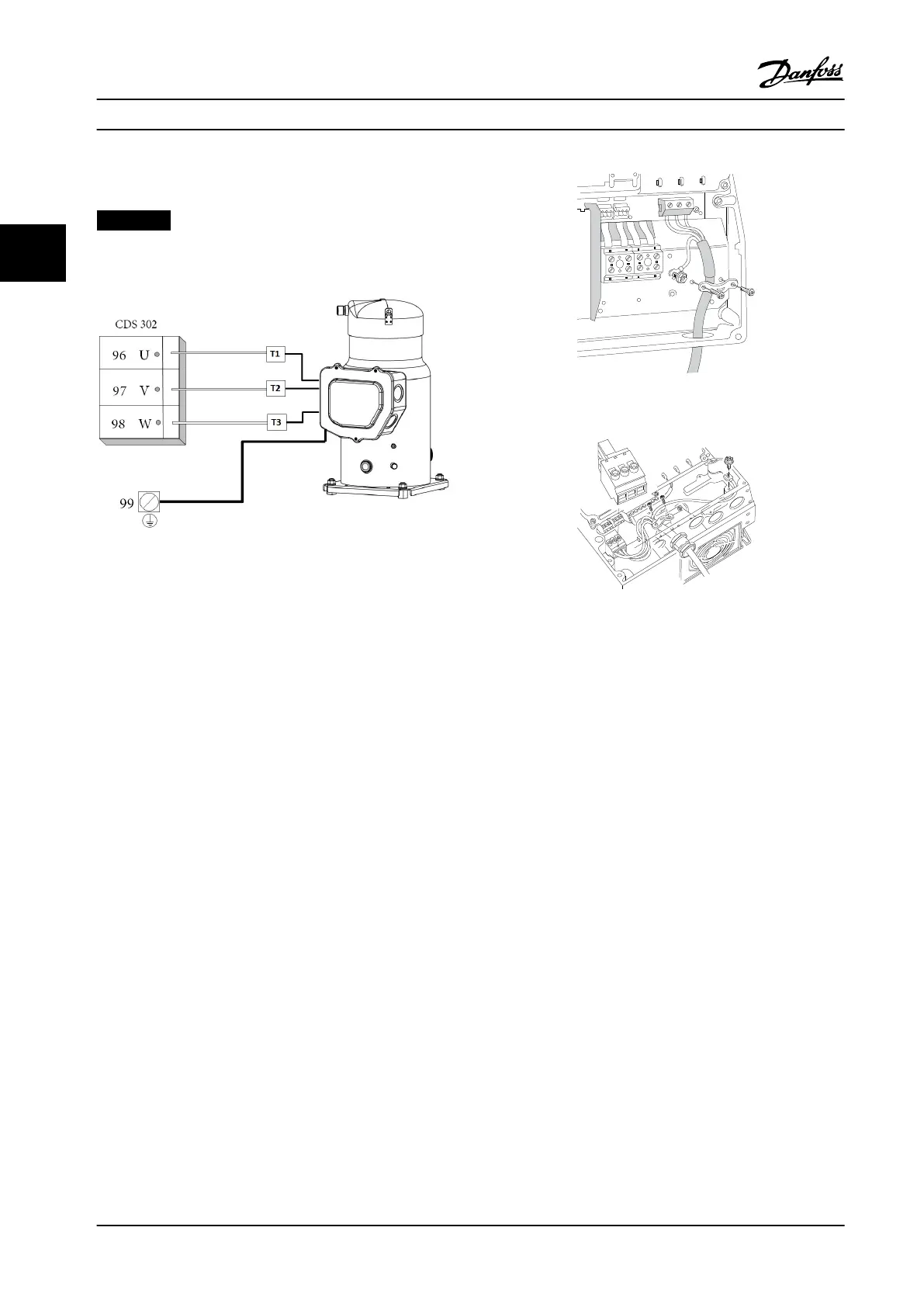

3.3.5 Motor Compressor Connection

NOTICE!

Always wire terminal 96 (U) to T1, 97 (V) to T2, and 98

(W) to T3.

Figure 3.13 Motor/Compressor Wiring

Motor compressor cable must be screened/armored. If an

unscreened/unarmored cable is used, some EMC

requirements are out of compliance. For more information,

see EMC specications.

1. Fasten decoupling plate to the bottom of the

frequency converter with screws and washers

from the accessory bag.

2. Attach motor compressor cable to terminals 96

(U), 97 (V), 98 (W).

3. Connect to ground connection (terminal 99) on

decoupling plate with screws from the accessory

bag.

4. Insert terminals 96 (U), 97 (V), 98 (W) and motor

compressor cable to terminals labeled MOTOR.

5. Fasten screened cable to decoupling plate with

screws and washers from the accessory bag.

6. Connect U, V, W for motor compressor clockwise.

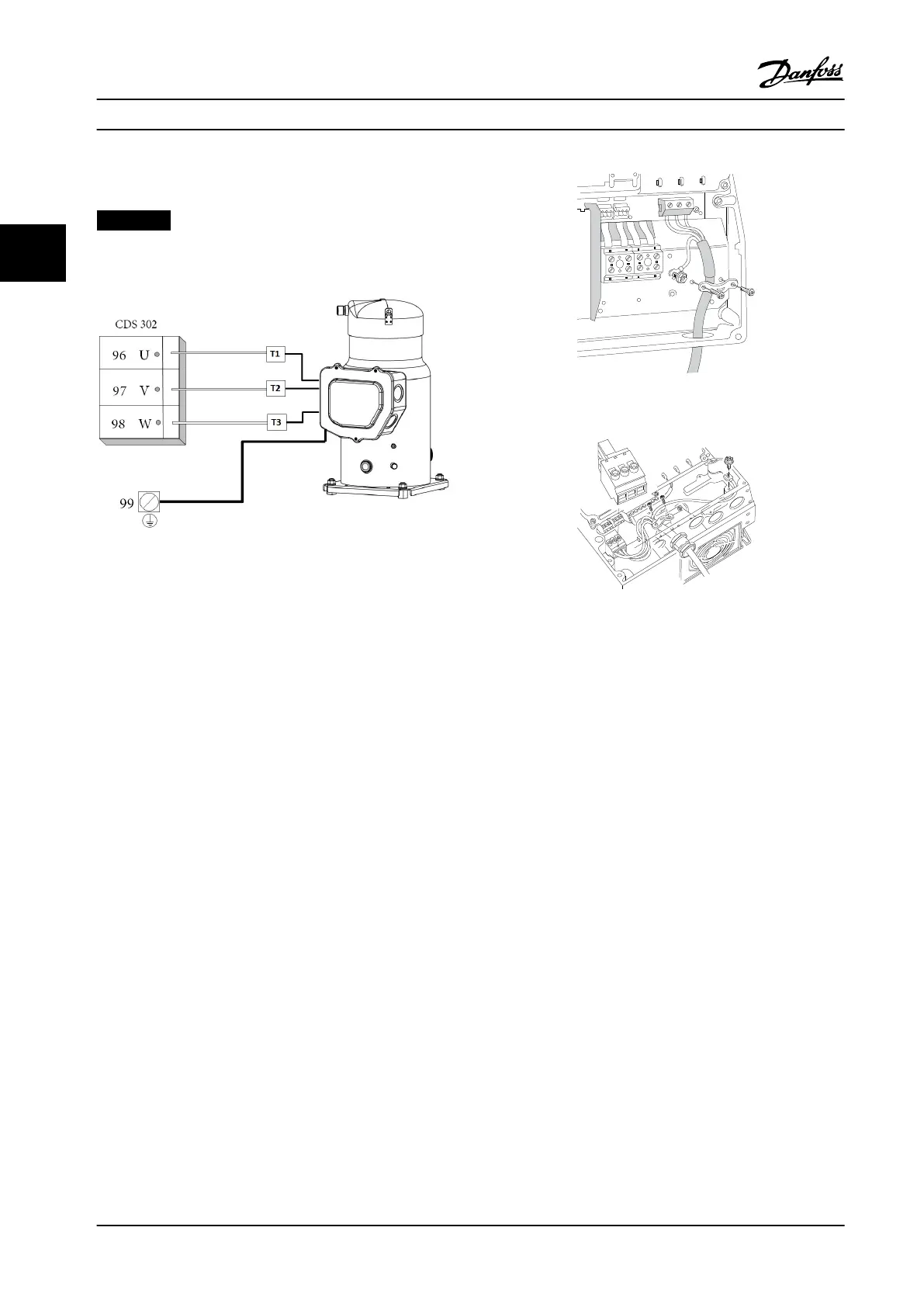

Figure 3.14 How to Connect to Motor Terminals B1/B2

L 1

L 2

L 3

91

92

93

130BT336.10

Figure 3.15 How to Connect to Mains and Ground without

Mains Disconnect

3.3.6 Motor Compressors Cables

Correct dimensioning of motor compressor cable cross-

section and length is described in the application manual.

•

Use a screened/armored motor compressor cable

to comply with EMC emission specications

•

Keep the motor compressor cable as short as

possible to reduce the noise level and leakage

currents

•

Connect the motor compressor cable screen to

both the decoupling plate of the frequency

converters and to the metal cabinet of the motor

compressor

•

Make the screen connections with the largest

possible surface area (cable clamp). Use the

supplied installation devices in the frequency

converter for making the screen connections.

How to Install

VLT

®

Compressor Drives CDS 302/CDS 303

20 Danfoss A/S © Rev. 2013-07-03 All rights reserved. MG34M422

33

Loading...

Loading...