Do you have a question about the Danfoss VLT CDS 303 and is the answer not in the manual?

Overview of the VLT® Compressor Drives and their application.

Details the operational sequence and startup behavior of the drives.

General safety advice, warnings, and precautions for operating the drives.

Details the Safe Torque Off (STO) safety function and its implementation.

Covers ambient temperature, altitude, and environmental requirements for installation.

Details physical installation aspects including mounting and dimensions.

Covers cable general guidelines, connections, and protection.

Recommendations for selecting fuses and circuit breakers for component protection.

Illustrates application examples of compressor drive systems.

Guides through the initial setup procedures for running the frequency converter.

Guide on programming the frequency converter using the Graphical Local Control Panel (LCP).

Details the functions of the keys on the Local Control Panel (LCP).

Overview of the Local Control Panel (LCP) display and its sections.

Parameters related to operating modes and display settings.

Parameters related to motor data, load compensation, and selection.

Parameters for reference handling, limitations, and ramp configuration.

Parameters for adjusting warning limits for current, speed, and reference.

Parameters for configuring digital inputs and outputs.

Parameters for configuring analog input and output signals.

Parameters for PID controllers, including speed and process control.

Parameters for configuring communication protocols and options.

Parameters for configuring Smart Logic Control (SLC) for user-defined actions.

Parameters for configuring special functions of the frequency converter.

Information on operating data, hardware, and software versions.

Parameters used for reading drive status and motor parameters.

Parameters for configuring the Cascade Controller for multi-compressor systems.

Parameters for configuring compressor functions like short cycle protection and oil return.

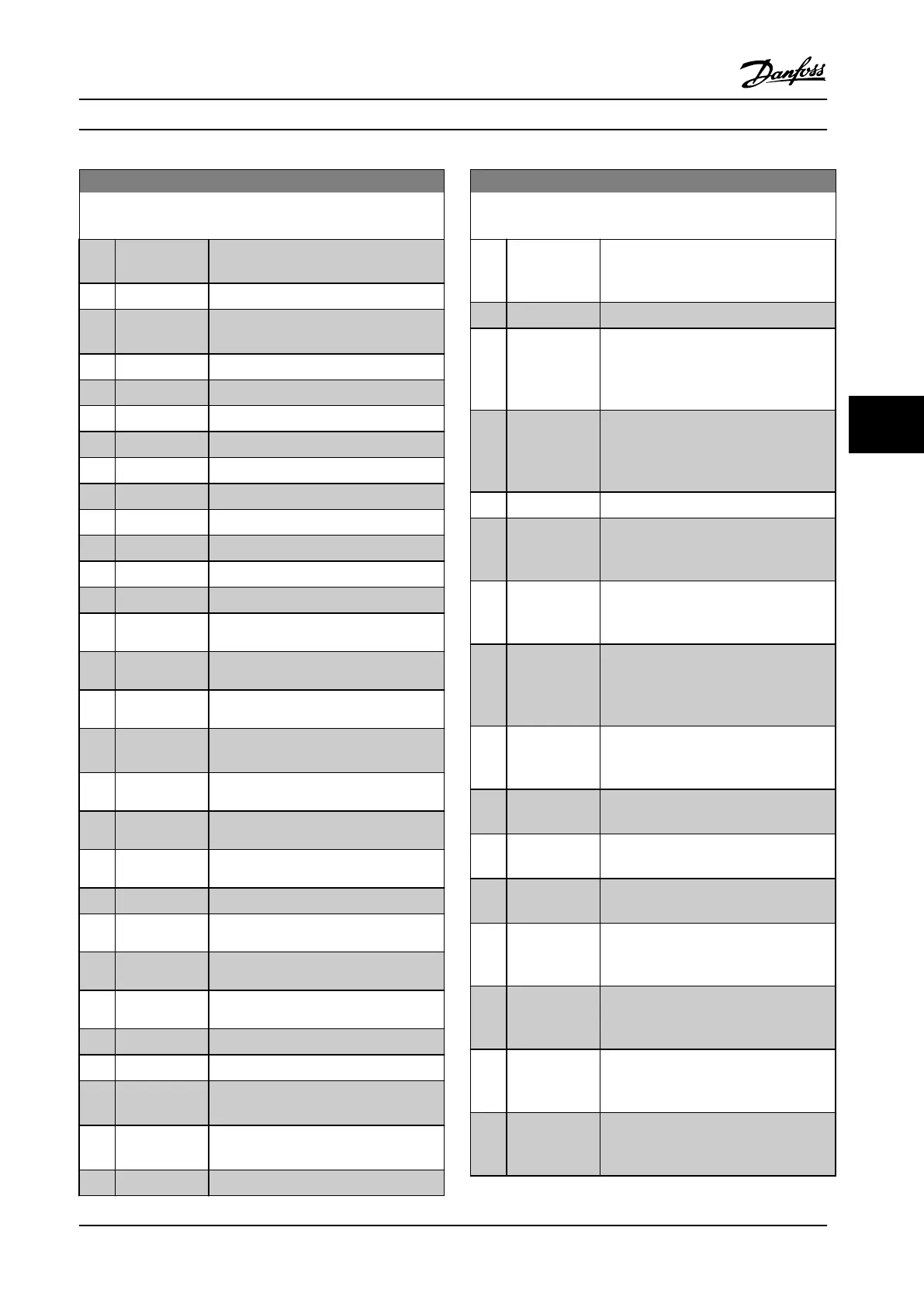

Lists parameters with descriptions, default values, and types.

Table of parameters related to operation and display settings.

Parameters related to motor data, load compensation, and selection.

Parameters for setting reference limits and ramp configurations.

Parameters for adjusting warning limits for current, speed, and reference.

Parameters for configuring digital inputs and outputs.

Parameters for configuring analog input and output signals.

Parameters for PID controllers, including speed and process control.

Parameters for configuring communication protocols and options.

Parameters for configuring special functions of the frequency converter.

Information on operating data, hardware, and software versions.

Parameters for configuring the Cascade Controller for multi-compressor systems.

Parameters for configuring compressor functions like short cycle protection and oil return.

Information on status messages, including warnings and alarms.

Specifications for mains supply of 3x200-240 V AC, including output and current.

Specifications for mains supply of 3x380-480 V AC, including output and current.

Specifications for mains supply of 3x525-600 V AC, including output and current.