Chapter 12 Troubleshooting

12-5

12.2

Troubleshooting for CPU Modules

Check the LED indicators and the error codes from the CPU module and refer to the following table for troubleshooting. V

in the Log column indicates the error is recorded in the log. X in the Log column indicates the error is not recorded in the

log. H in the Log column indicates whether or not you can set recording the error in the log in HWCONFIG.

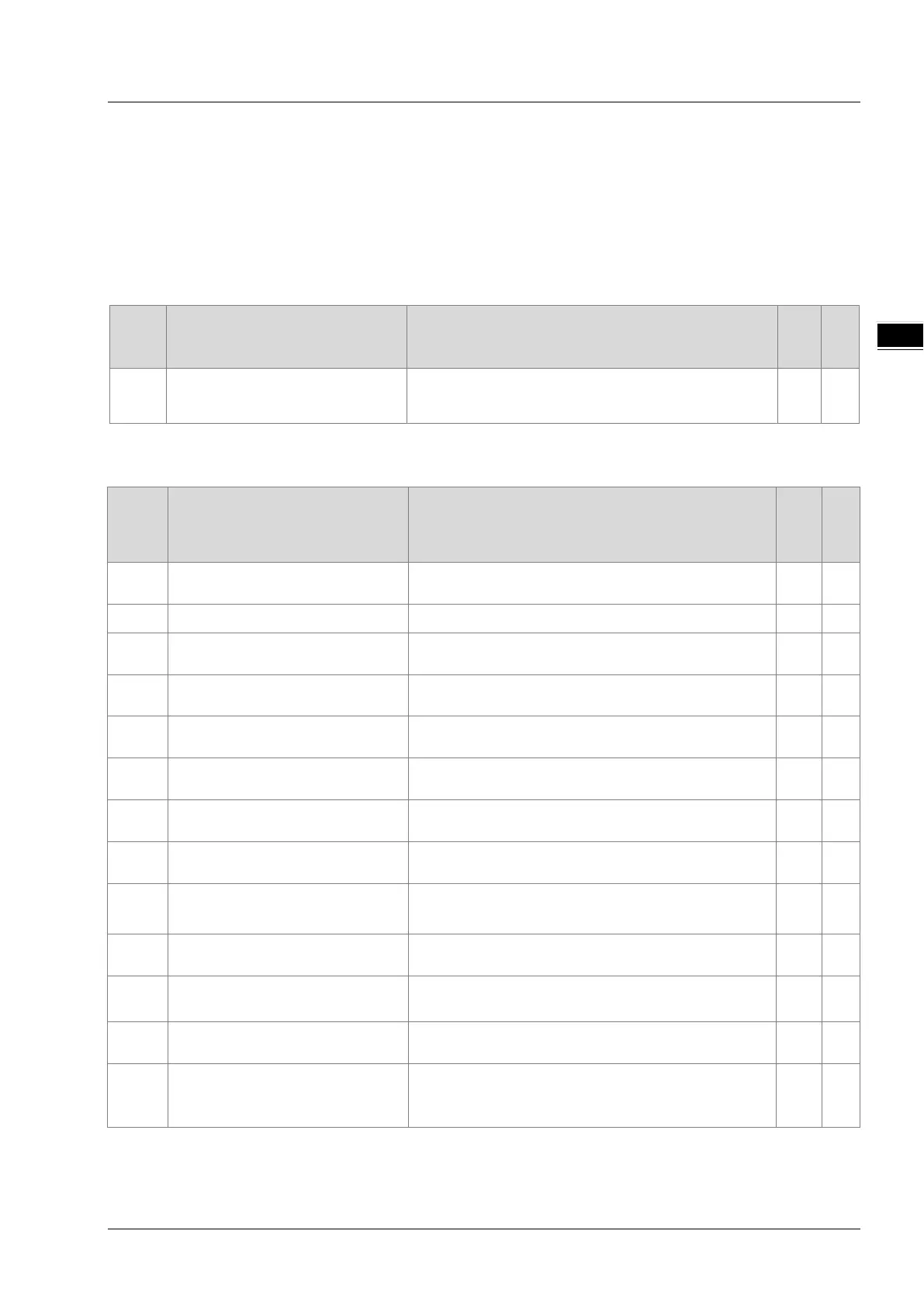

12.2.1

ERROR LED Indicators Are ON

Error

Code

Description Solution Flag Log

000A Scan timeout

1. Check the setting of the watchdog timer in HWCONFIG.

2. Check whether the program causes a long scan time

SM8 V

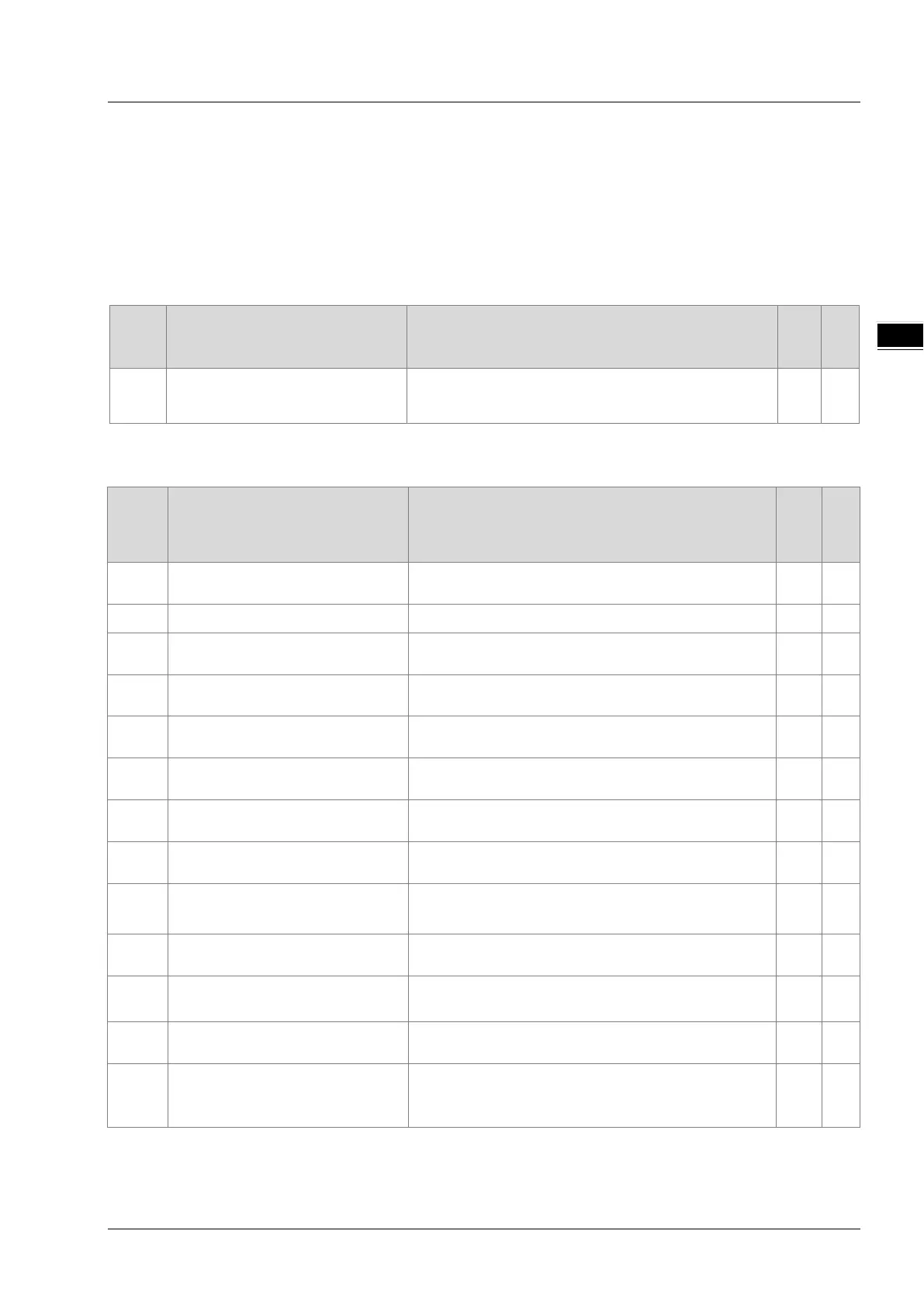

12.2.2

ERROR LED Indicators Blinking Every 0.5 Seconds

Error

Code

(16#)

Description Solution Flag Log

000C

The program in the PLC is

damaged.

Download the program again. SM9 V

0010 CPU memory is denied. Contact the factory. SM9 V

002E

CPU external memory access is

Contact the factory. SM9 V

002F

PLC programs are not consistent

with the system logs.

Download the program again.

SM34

V

0102

The interrupt number exceeds the

range.

Check the program, compile the program again, and

download the program again.

SM5 X

0202

The MC instruction exceeds the

range.

Check the program, compile the program again, and

download the program again.

SM5 X

0302

The MCR instruction exceeds the

Check the program, compile the program again, and

download the program again.

SM5 X

0D03

The operands used in DHSCS are

Check the program, compile the program again, and

download the program again.

SM5 X

0E05

The operands HCXXX used in

DCNT are not used properly.

Check the program, compile the program again, and

download the program again.

SM5 X

200A Invalid instruction

Check the program, compile the program again, and

download the program again.

SM5 V

6010

The number of MODBUS TCP

connections exceeds the range.

Check the number of superior devices (maximum is 32).

SM

1092

V

6011

The number of EtherNet/IP

connections exceeds the range.

Check the number of connections (maximum is 16).

SM

V

C000

-

The program syntax is incorrect.

Save the PLC program and hand the file to the company

or the technicians.

Loading...

Loading...