REV.-A

a. Push Tractor Feed

1. Use the pull-out unit.

2. Do not perform reverse

feeding greater than 1/6 inch.

3. After paper end detection, accuracy of paper feed cannot be assured and reverse feeding cannot

be performed.

b. Push Pull Feed

1. Remove the pull-out unit and attach the pull tractor unit.

2. Do not loosen the paper between the platen and pull tractor unit.

3. Adjust precisely the horizontal position of the pull and push tractor.

4. Do not perform reverse feeding greater than 1/6 inch.

5. Do not perform reverse feeding after

the paper end is detected.

c. Pull Tractor Feed

1. Remove the pull-out unit and attach the pull tractor unit.

Line Spacing

1/6 inch, 1/’8 inch, or programmable in units of 1/216 inch

Paper Insertion

From rear

Paper-Feed Speed

Approximately 95 ins/line (1/6 inch line feeding)

Approximately 75 ins/line (1/6 inch in page feed)

Paper Specifications See Table 1-3 through 1-6

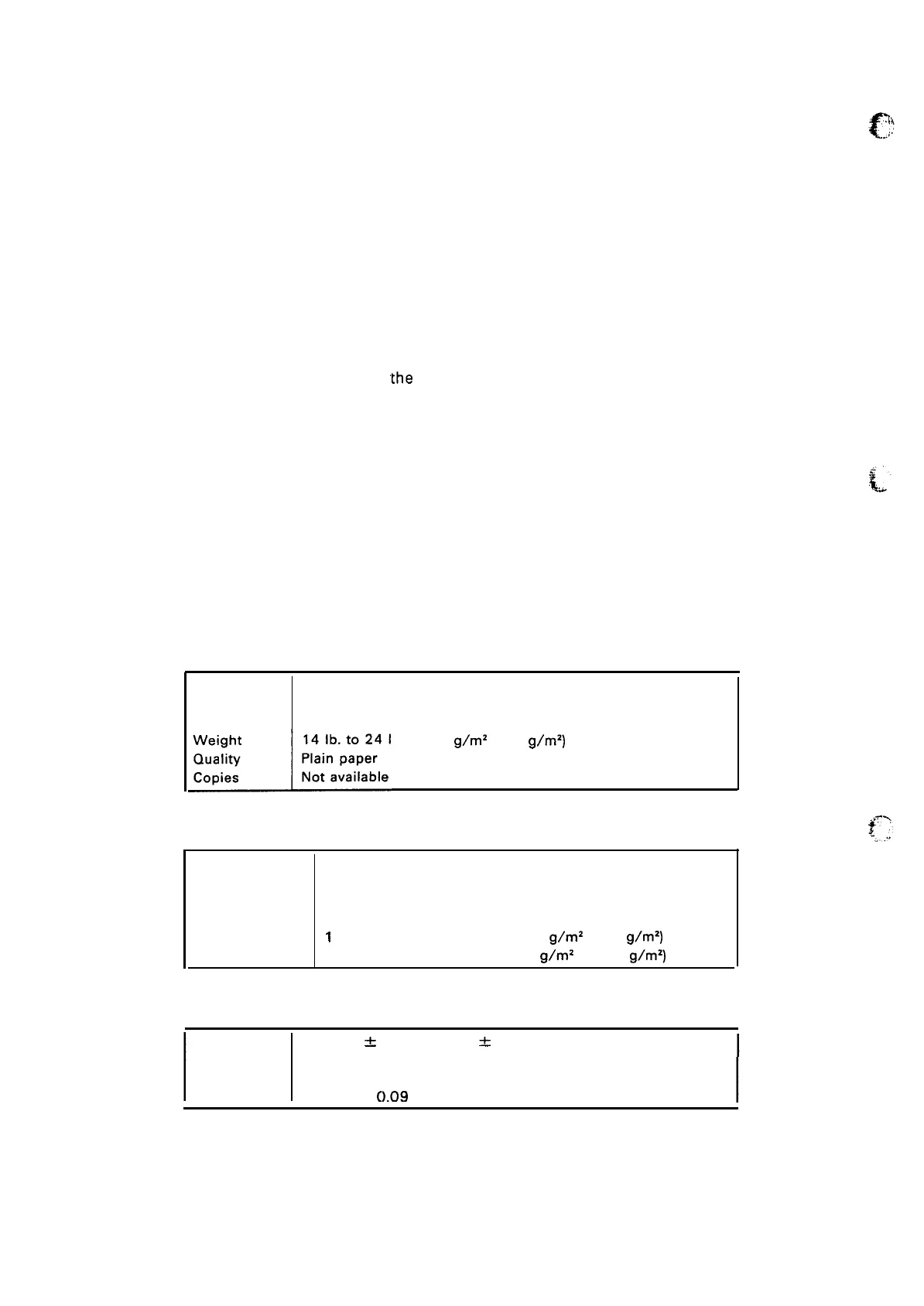

Table 1-3. Cut-Sheet Specifications

Width

182 mm to 257

mm (7.15 in. to 10.1 in.)

Length

182 mm to 364 mm (7.15 in. to 14.3 in.)

Thickness

0.065 mm to 0.14 mm (0.0025 in. to 0.0055 in.)

Si_k&lL

14 lb. to 24 lb. (52.3 g/mz to 90

g/m2)

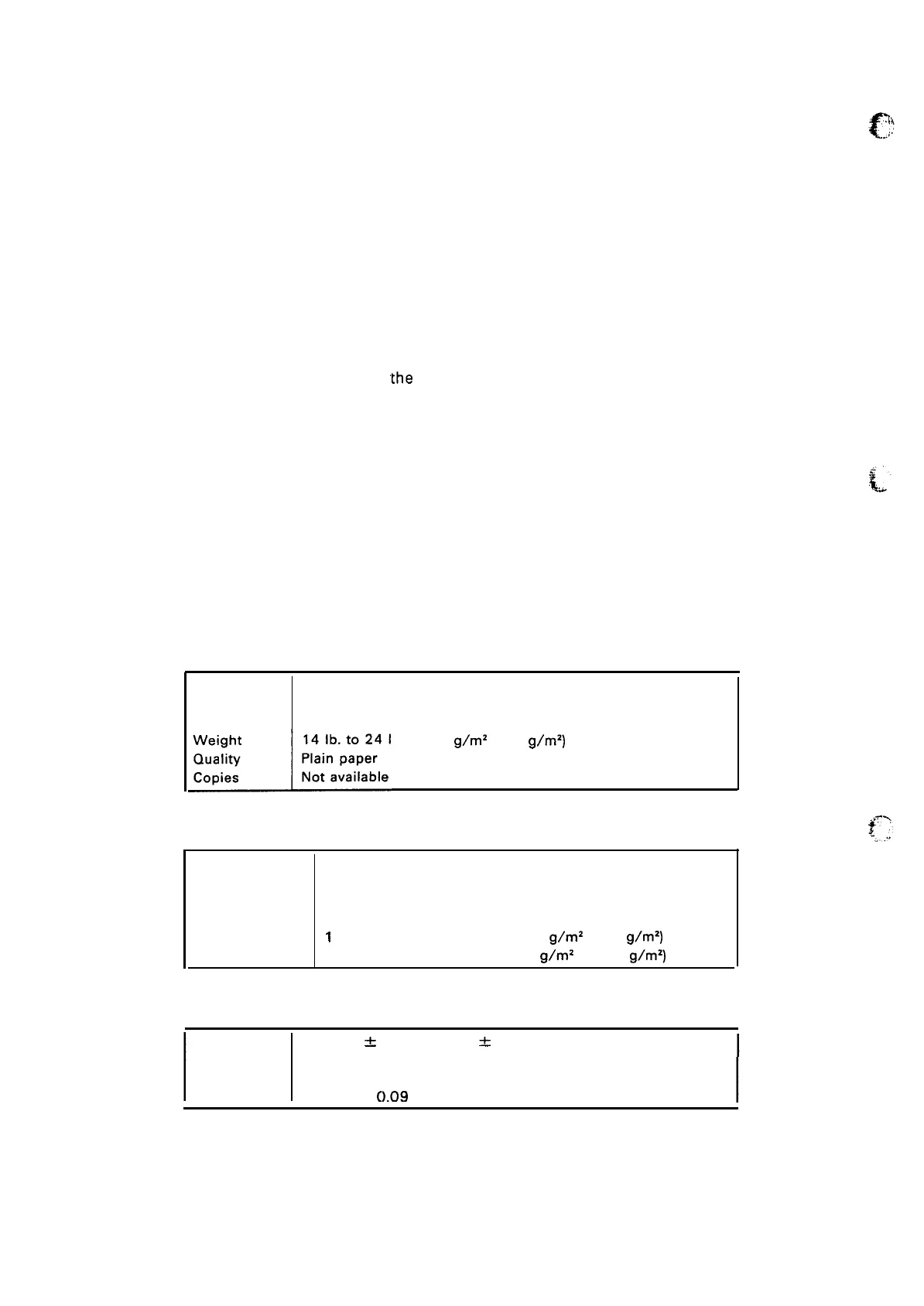

Table 1-4. Continuous Paper Specifications

Width

101 mm to 254 mm (4.0 in. to 10.0 in.)

Copies

3 sheets (1 original and 2 copies)

Quality

Plain paper

Total Thickness

0.065 mm to 0.25 mm (0.0025 in. to 0.01 in.)

Weight

1

sheet - 14 lb. to 22 lb., (52.3 g/m2 to 82

g/m2)

3 sheets -- 12 lb. to 15 lb., (40 g/mz to 58.2

g/m2)

each

Table 1-5. Roll Paper Specifications

Width

216 mm

& 3 mm (8.5 in. & 0.12 in.)

Weight 14 lb. to 17 lb. (45 kg to 55 kg)

Quality

Plain paper

Thickness

0.07 mm to

C).09

mm (0.0028 in. to 0.0035 in.)

1-4

Loading...

Loading...