REV.-A

3.2.4 Cut Sheet Feeder Preventive Maintenance

The cut sheet feeder C806 12* is well designed and requires only a minimum of preventive maintenance,

as follows:

a) General cleaning of the device.

b) Checking the mechanical functions.

3.2.4.1 Cleaning

a) Brush off all paper dust.

b) Check the surfaces of the paper loading and paper ejecting rollers.

NOTE: If one of the paper loading rollers is damaged, or if wear is uneven, both rollers must be replaced.

WARNING

Regularly check the shafts of the paper loading and paper ejecting rollers. If the printer fails to move

*.

,.

$:

the paper, open the right side cover and check the gear wheels for wear or damage.

f“

...,

:,,

,.,,

,,

3.2.4.2 Lubrication

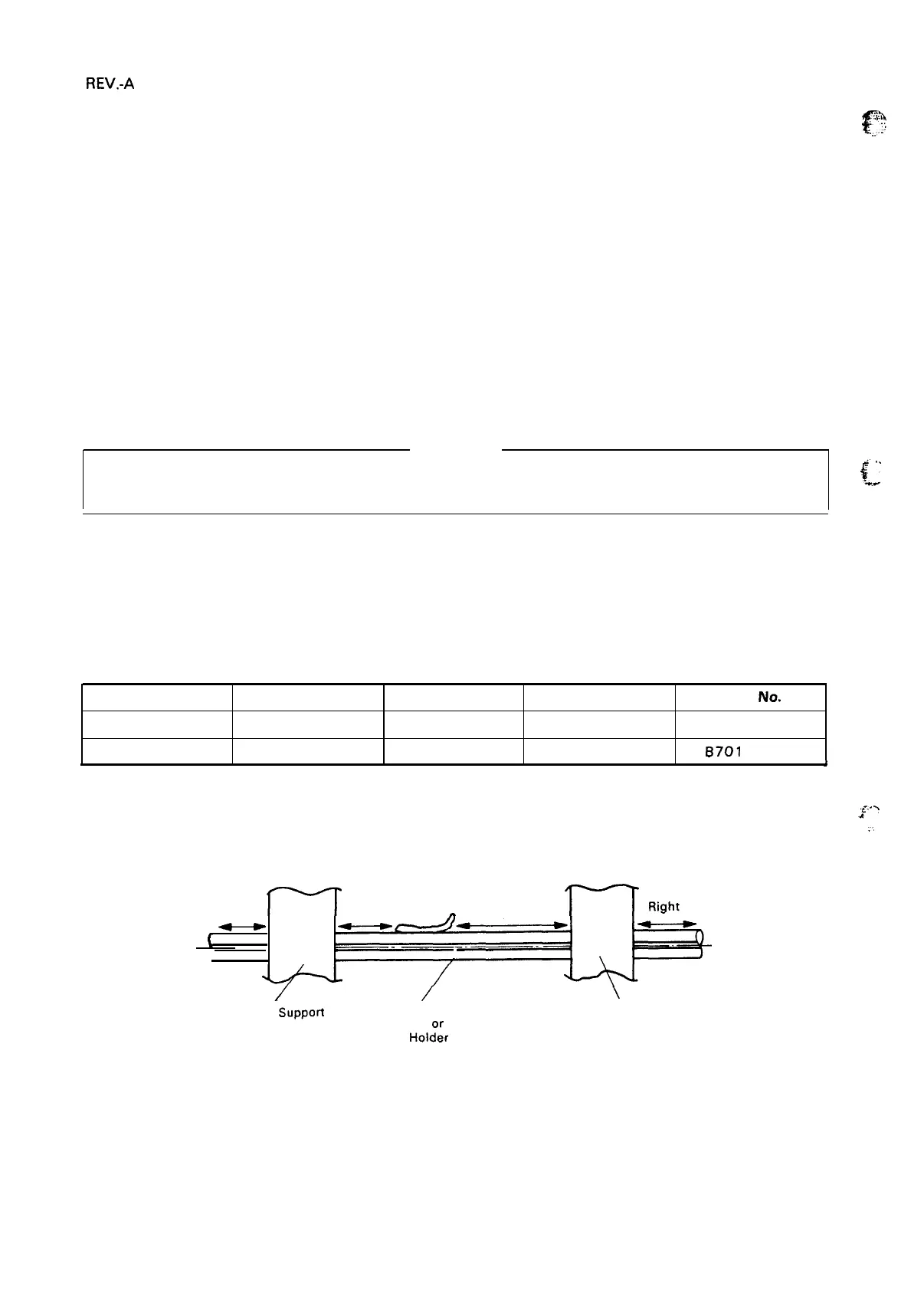

EPSON recommends that the points indicated in Figures 3-10 and 3-11 be lubricated with EPSON O-3

and G-1 4 (see Table 3-7). These lubricants have been thoroughly tested and have been found to fully

comply with the needs of the cut sheet feeder.

Table 3-7. Lubricants

Classification

Designation

Capacity

Availability

Part

No.

Oil

o-3

40 cc

E

B7 10300001

Grease

G-1 4

40 g

E

B701

400001

J

E: EPSON exclusive

Lubricate the paper

product

support shaft and the paper holder shaft using a cloth moistened with O-3.

Left

~

Cloth

-

m

R,,,

(

—

/

Paper’

SuppOr’t

Paper Support Shaft

Pager

Hol;~r Shaft

Figure 3-10. Lubrication

\

Paper Support

Point (1)

.$.-.

*

.

-

,.,

.

3-14

Loading...

Loading...