Proper maintenance assures

occurrence of malfunctions.

REV.-A

optimal and long-term printer performance and and minimizes the

6.1 PREVENTIVE MAINTENANCE

The case exterior should be regularly cleaned with alcohol. Occasionally

the mechanism to remove accumulated dirt, dust, and paper particles.

vacuum clean the interior of

After the unit has been cleaned, check that it is adequately lubricated (refer to Section 6.2, below). Before

returning the printer to the customer, inspect the springs, paper-feed rollers, and the basic operation

of the unit.

WARNING

Be sure to disconnect the printer from the power supply before maintenance. Do not apply thinner,

trichloroethylene,

or ketone-based solvents to any of the printer’s plastic components.

6.2

LUBRICATION AND ADHESIVE APPLICATION

EPSON recommends lubrication at the points illustrated in Figure 6-2. Table 2 provides a list of these

points, and the recommended lubricant to be used for each. The lubricants-EPSON O-2, EPSON G-20,

EPSON G-26, and EPSON G-37–have all been thoroughly tested and fully meet the needs of this printer.

(Table 6-1 lists details of these lubricants.)

Before applying any lubricant, make sure that the part to be lubricated is clean. Do not apply excess

lubrication, as this can potentially cause damage.

Following its disassembly or replacement, adhesive must be applied to the part indicated in Table 6-3.

EPSON recommends application of

Neji lock #2 (G) adhesive to the point illustrated in Figure 6-1. When

applying the adhesive, be careful that no excess overflows onto nearby parts.

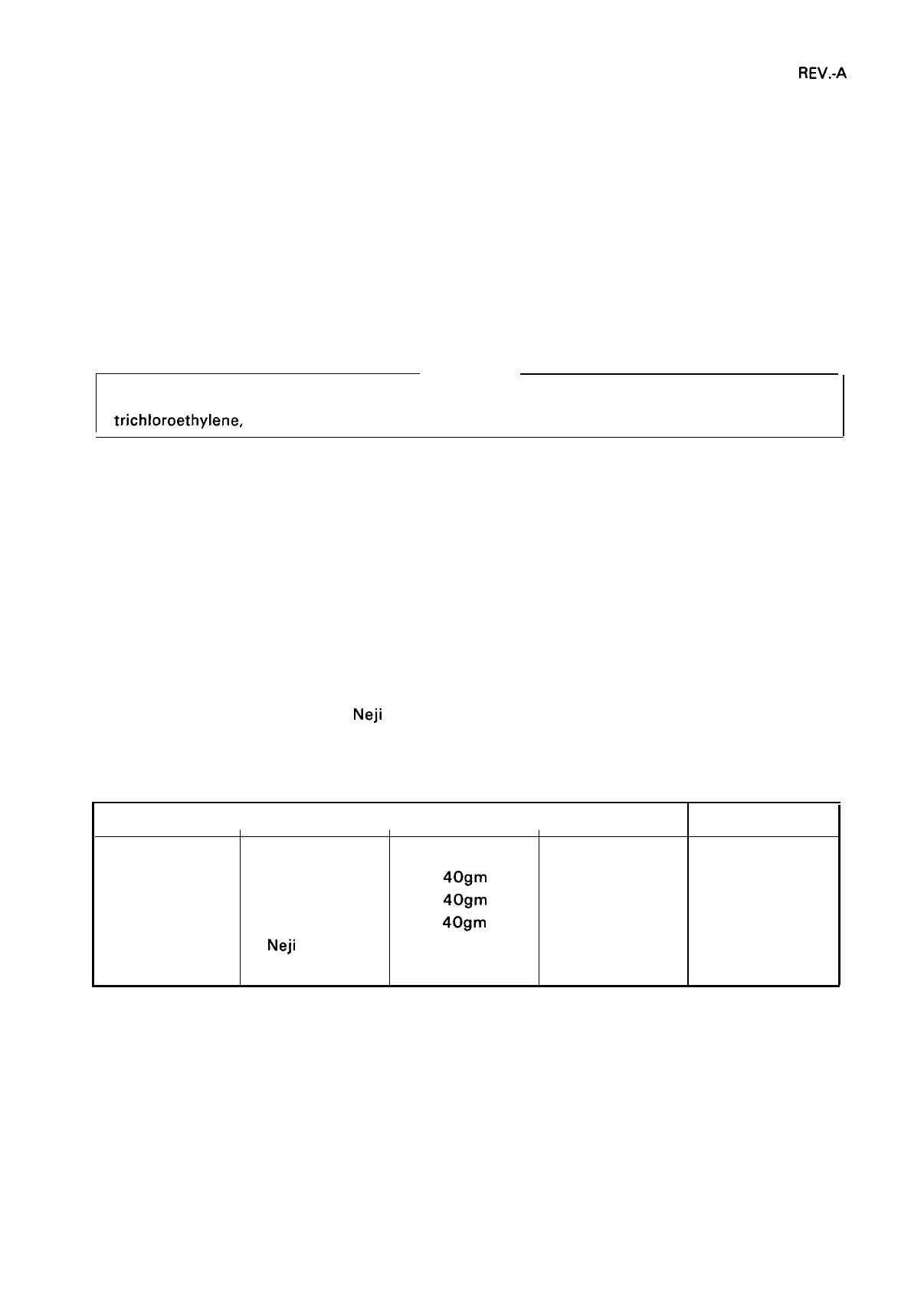

Table 6-1. Lubrication and Adhesive

Type

I

Name

I

Capacity

I

Availability

Oil

Grease

Grease

Grease

Adhesive

o-2

G-20

G-26

G-37

Neji lock #2

(G)

40CC

40gm

40gm

40gm

E

E

E

E

E

Parts No.

B7 10200001

B702000001

B702600001

B703700001

B730200200

E: EPSON-exclusive product

6-1

Loading...

Loading...