113

EN

Press the Parameter selection button. The LED indicator on the button must light up.

Use the adjusting dial to set the desired amperage.

The amperage value is shown in the left-hand digital display.

All welding parameter set values that have been set using the adjusting dial remain

stored until the next time they are changed. This applies even if the power source is

switched off and on again in the meantime.

Open the gas stop valve on the TIG gas valve torch

Set the desired shielding gas flow rate on the pressure regulator

Start welding (ignite the arc)

Igniting the arc The welding arc is ignited by touching the workpiece with the tungsten electrode.

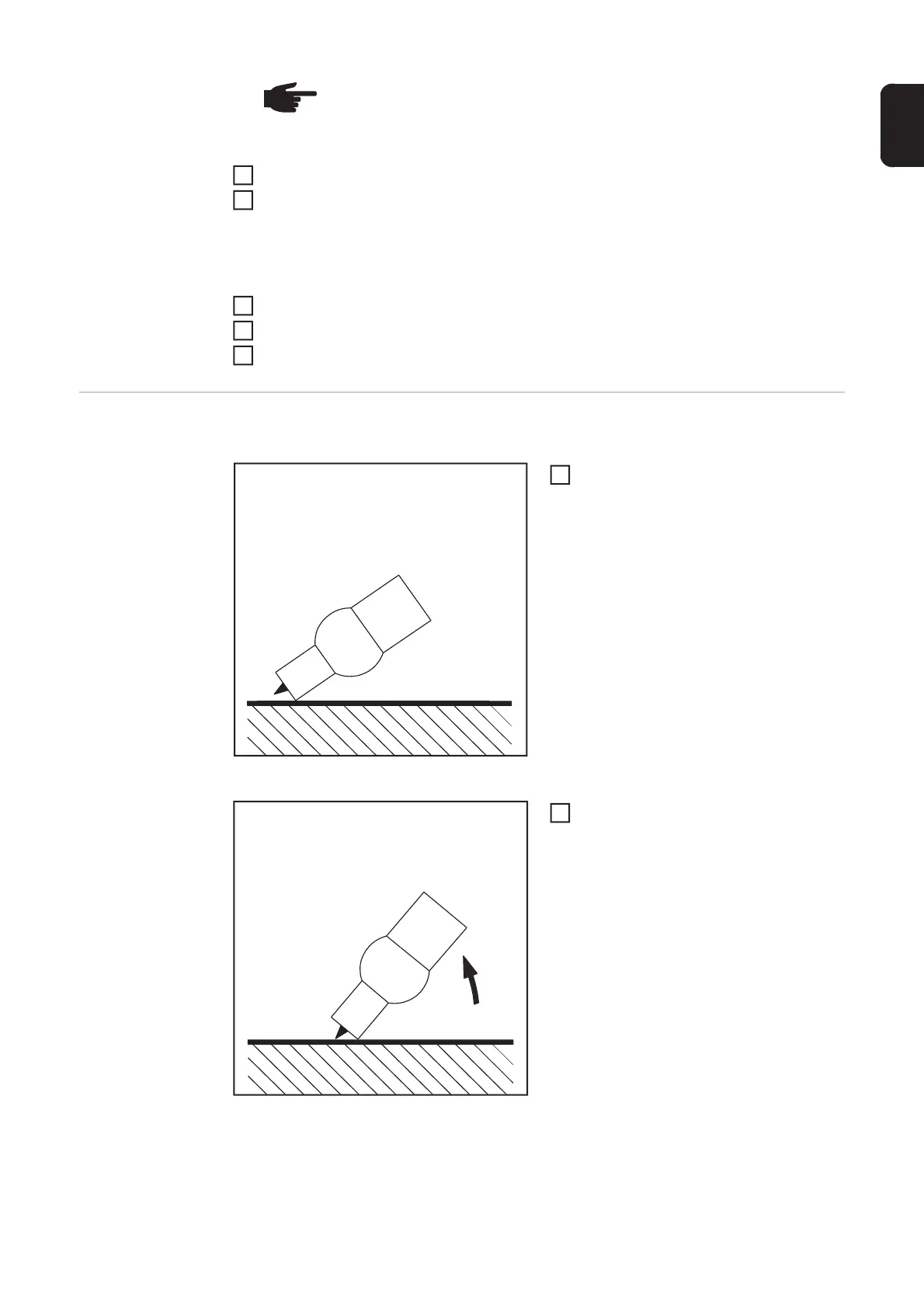

Placing the gas nozzle down

Place the gas nozzle on the ignition lo-

cation so that there is a gap of 2-3 mm

(0.08 - 0.12 in.) between the tip of the

tungsten electrode and the workpiece.

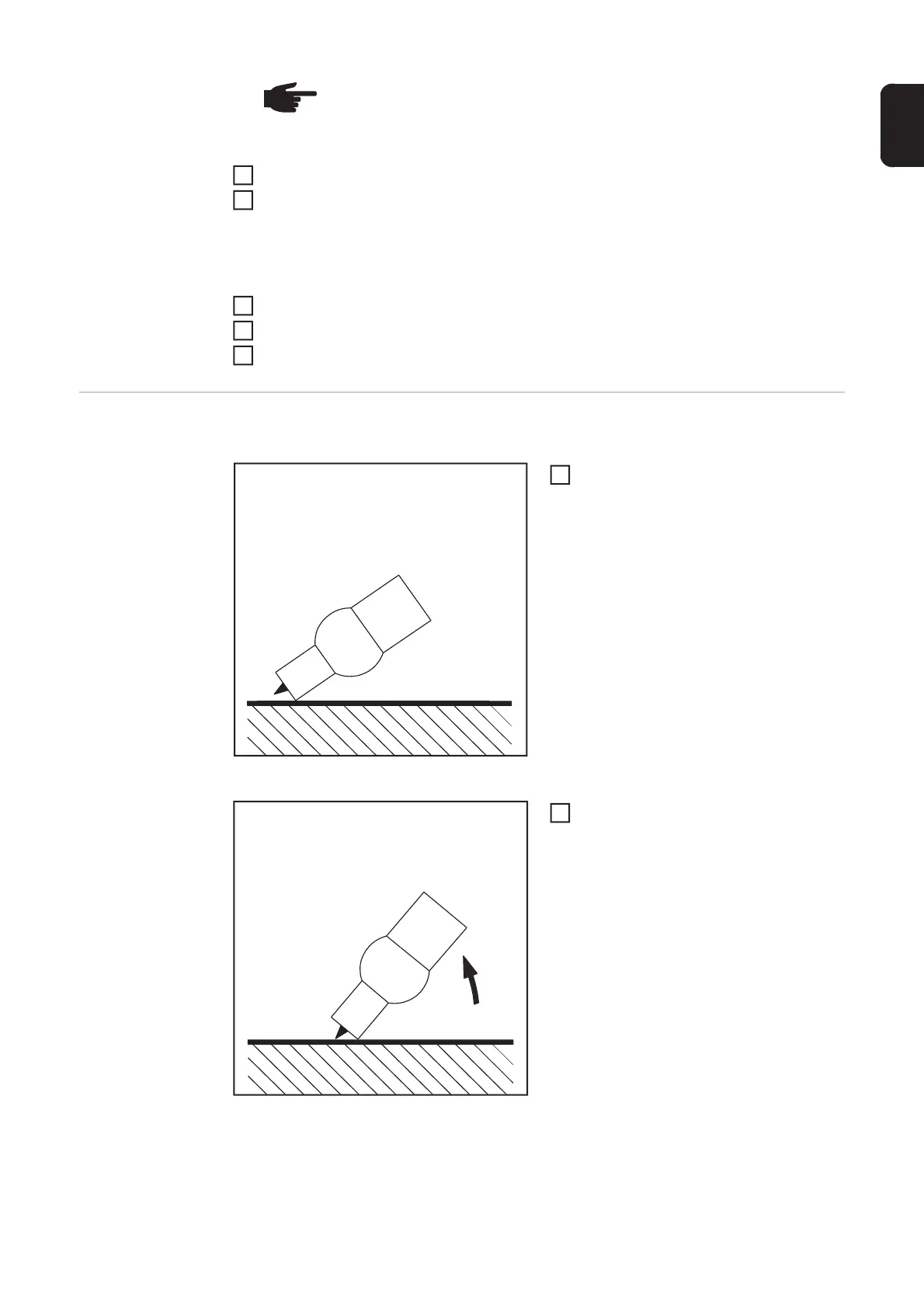

Arc ignites when electrode is touched down on workpi-

ece

Gradually tilt the welding torch up until

the tungsten electrode touches the

workpiece

NOTE! Parameters that have been set on a system component control panel

(e.g. wire feed unit or remote control) might not be able to be changed on the

power source control panel.

3

4

5

7

1

2

Loading...

Loading...