66

TPS 2700 CMT

power source

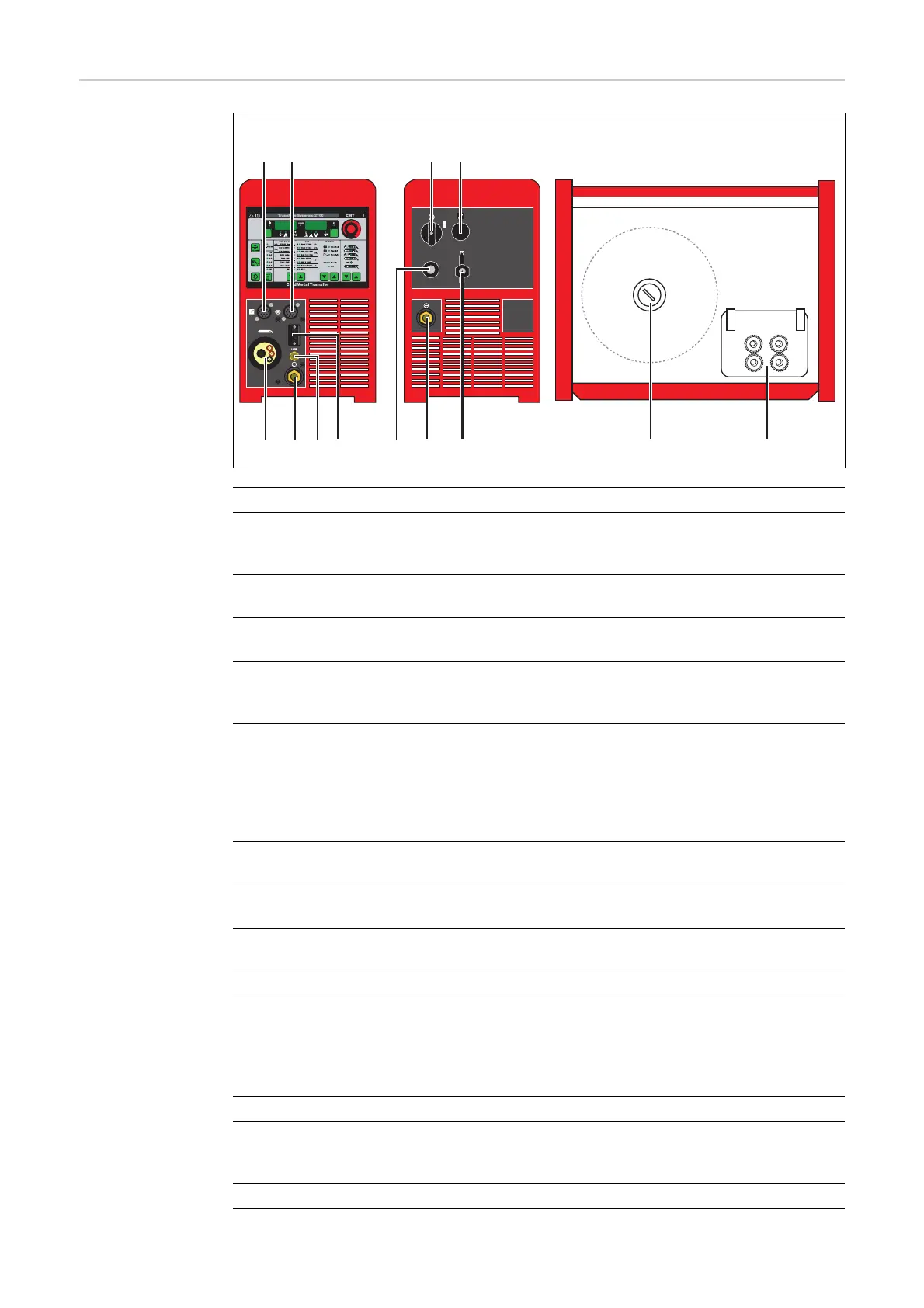

Front view Rear view Side view

No. Function

(1) LocalNet connection

Standardised connection socket for system add-ons (e.g. remote control, Job-

Master torch, etc.)

(2) Motor control connection

for connecting the control line from the CMT drive unit

(3) Welding torch control connection

for the welding torch control plug

(4) LHSB connection

for connecting the LHSB cable from the CMT drive unit (LHSB = LocalNet High-

Speed Bus)

(5) (-) - Current socket with bayonet latch

for:

- connecting the grounding (earthing) cable during MIG/MAG welding

- the current connection for the TIG welding torch

- connecting the electrode cable or grounding (earthing) cable during MMA

welding (depending on the type of electrode used)

(6) Welding torch connection

for connecting the welding torch

(7) Mains switch

for switching the power source on and off

(8) Blanking cover

reserved for a LocalNet connection

(9) Shielding gas connection

(10) (+) - Current socket with bayonet latch

for:

- connecting the grounding (earthing) cable during TIG welding

- connecting the electrode cable or grounding (earthing) cable during MMA

welding (depending on the type of electrode used)

(11) Mains cable with strain relief device

(12) Wirespool holder with brake

for holding standard wirespools weighing up to 16 kg (35.27 lbs) and with a max.

diameter of 300 mm (11.81 in)

(13) 4 roller drive

(7) (8)

(9)

(10)(11) (13)(12)

Loading...

Loading...