Maintenance 80

Cod. 523340

Rev. 10/1016

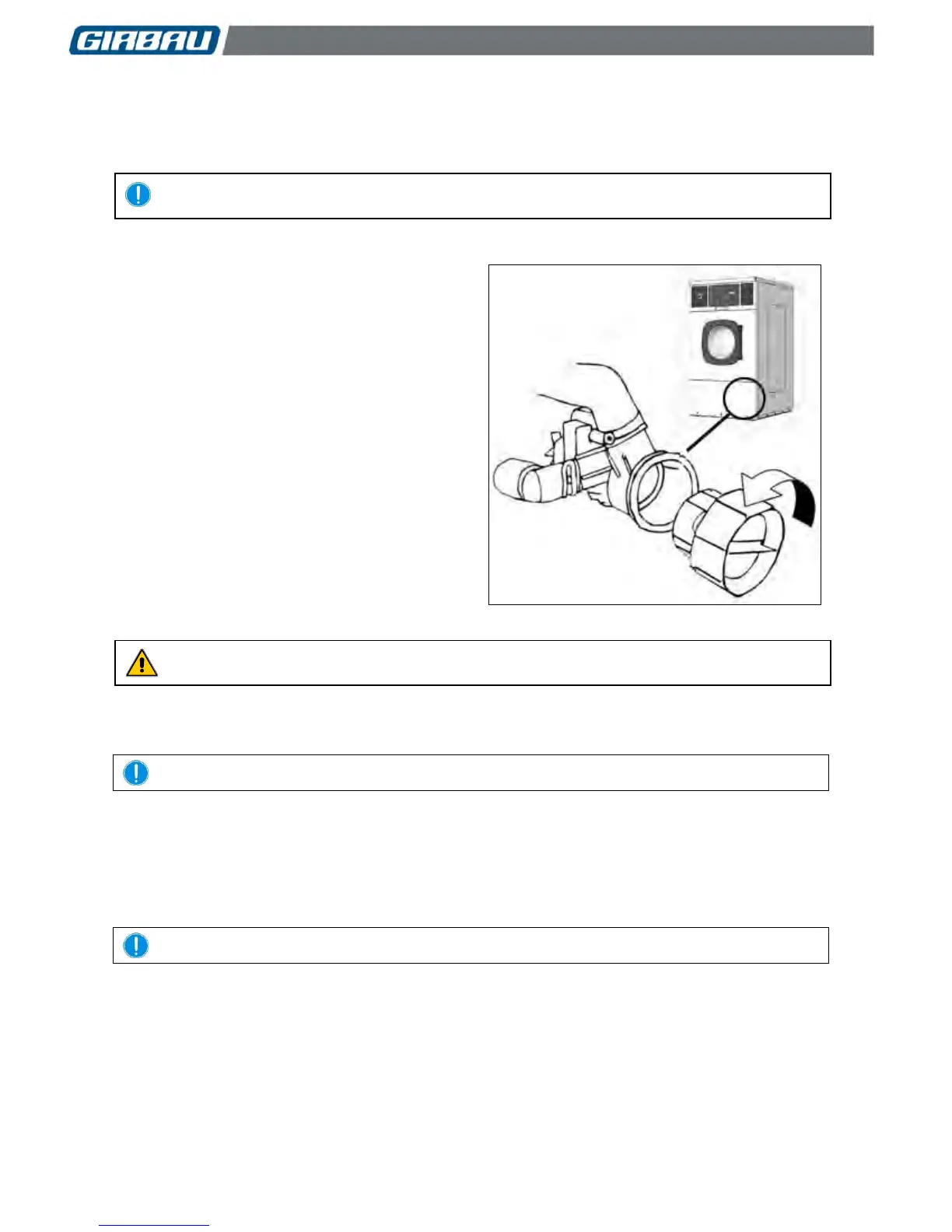

10.6. Cleaning the drain pump

(Drain pump washers. Fig. 10.3)

Only to be performed by the Authorised Technical Service

Required tools. Disassembly of the lower front panel: Torx. T25 screwdriver

Before disassembling the lower front panel of

the washing machine, disconnect and

mechanically lock the external switch, and close

and mechanically lock the manual water inlet

valves.

Empty any residual water contained in the drain

ducts, placing the corrugated rear tube

horizontally on the floor. The water will come out

of the end.

Disassemble the lower front panel. The draining

pump is accessible.

Turn the filter counter-clockwise and separate it

from the pump body.

Clean the filter and any possible deposits from

the inside of the pump body.

Assemble the filter and the draining pump.

Replace the bottom panel.

Connect the external switch and open the

manual water inlet valves.

Begin a washing program and check that there

are no water leaks.

The bottom front cover is a stabilising element of the washer cabinet. Make sure that it is

properly fitted and fastened.

10.7. Checking the condition of the bearing housing seals

Only to be performed by the Authorised Technical Service

At regular intervals check that no water is leaking out of the bearing drain pipe located at the back of the washer

at the bottom. Water loss indicates that the seals are in poor condition and need to be replaced.

10.8. General Overhaul

Only to be performed by the Authorised Technical Service

As preventive maintenance action, it is very important to request the Authorised Technical Service for a

periodic overhaul of the washing machine.

Recommended periodicity: once a year or every 3000 washing cycles.

When performing this overhaul on HS-6008 / EH020 models, due to the wear and tear it is subject to, we

recommend carefully checking the door seal and replacing it if wear is noticed.

Loading...

Loading...