8 Programming: Cycles

152

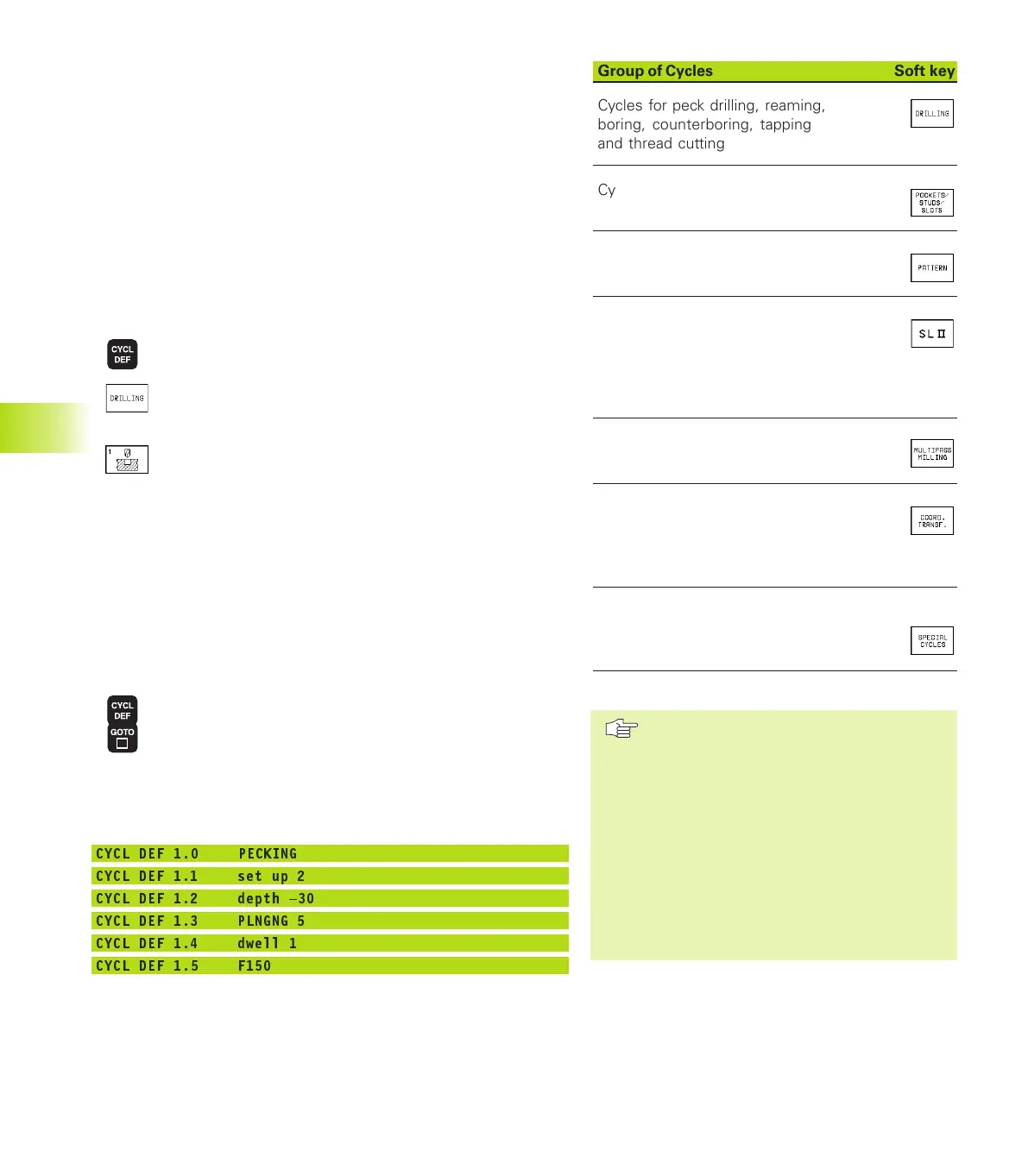

8.1 General Information on Cycles

Frequently recurring machining cycles that comprise several

working steps are stored in the TNC memory as standard cycles.

Coordinate transformations and other special cycles are also

provided as standard cycles. The table at right lists the various cycle

groups.

Fixed cycles with numbers 200 and over use Q parameters as

transfer parameters. Parameters with specific functions that are

required in several cycles always have the same number: For

example, Q200 is always assigned the setup clearance, Q202 the

plunging depth, etc.

Defining a cycles via soft-key structure

ú

The soft-key row shows the available groups of cycles

ú

Press the soft key for the desired group of cycles, for

example DRILLING for the drilling cycles

ú

Select the desired cycle, for example PECKING. The

TNC initiates the programming dialog and asks all

required input values. At the same time a graphic of

the input parameters is displayed in the right screen

window. The parameter that is asked for in the dialog

prompt is highlighted

ú

Enter all parameters asked by the TNC and conclude

each entry with the ENT key

ú

The TNC terminates the dialog when all required data

have been entered

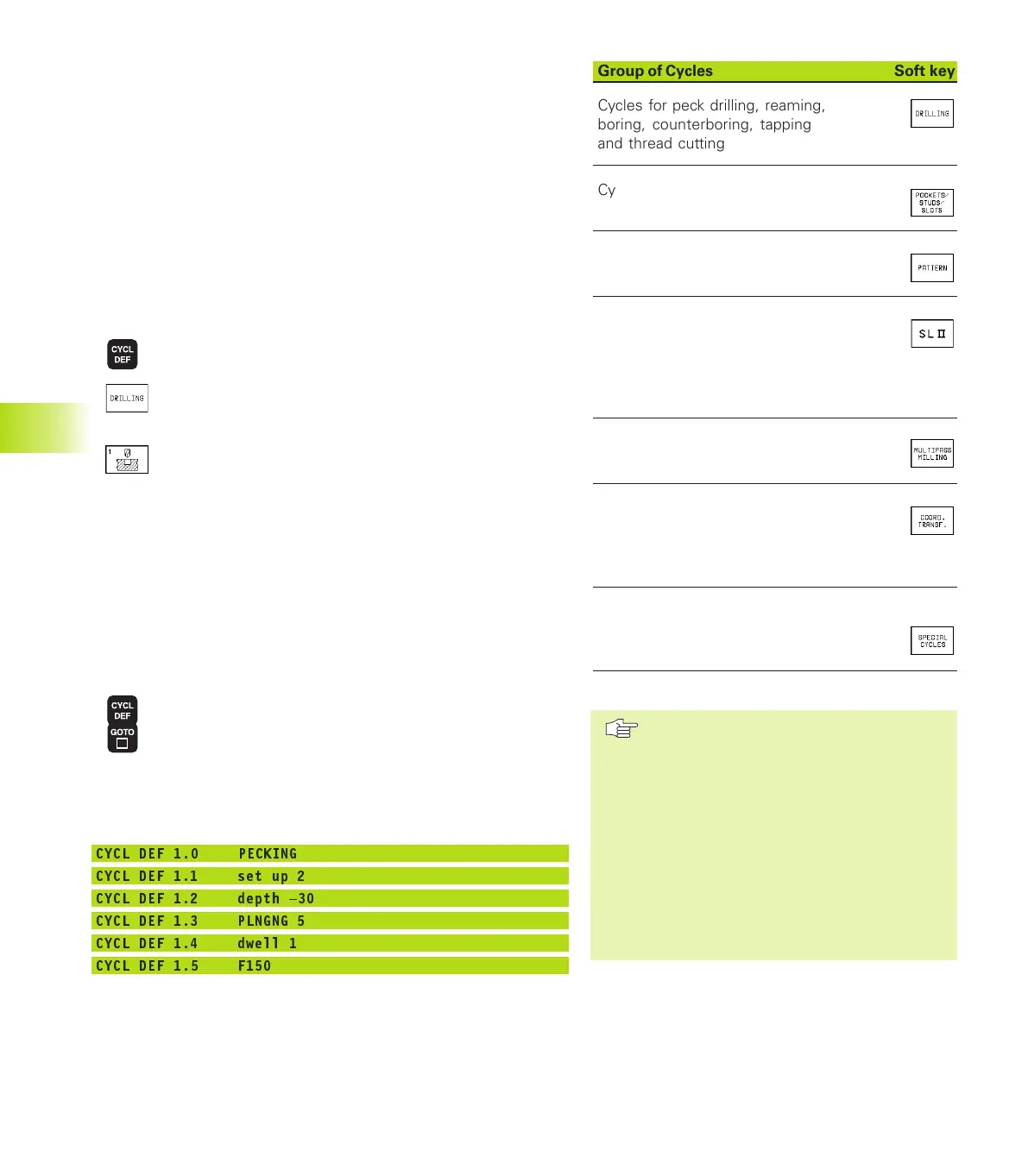

Defining a cycle using the GOTO function

ú

The soft-key row shows the available groups of cycles

ú

Overview of all cycles available in the TNC

ú

Enter the cycle number, or use the cursor key to select

the number from the list. Then confirm your entry or

selection with ENT.

Example NC blocks

CYCL DEF 1.0 PECKING

CYCL DEF 1.1 set up 2

CYCL DEF 1.2 depth 30

CYCL DEF 1.3 PLNGNG 5

CYCL DEF 1.4 dwell 1

CYCL DEF 1.5 F150

Group of Cycles Soft key

Cycles for peck drilling, reaming,

boring, counterboring, tapping

and thread cutting

Cycles for milling pockets, studs

and slots

Cycles for producing hole patterns,

such as circular or linear patterns

SL (Subcontour List) cycles, which

allow the contour-parallel machining of

relatively complex contours consisting

of several overlapping subcontours,

cylinder surface interpolation

Cycles for face milling of flat or

twisted surfaces

Coordinate transformation cycles

which enable datum shift, rotation,

mirror image, enlarging and reducing

for various contours

Special cycles such as dwell time,

program call, oriented spindle stop

and tolerance

8.1 General Information on Cycles

If you use indirect parameter

assignments in fixed cycles with

numbers greater than 200 (e.g. Q210 =

Q1), any change in the assigned

parameter (e.g. Q1) will have no effect

after the cycle definition. Define the

cycle parameter (e.g. Q210) directly in

such cases.

In order to be able to run cycles 1 to 17

on older TNC models, you must program

an additional negative sign before the

values for safety clearance and plunging

depth.

kkap8.pm6 30.06.2006, 07:03152

www.EngineeringBooksPdf.com

Loading...

Loading...